Product Description

In the sterilized, high-pressure world of modern manufacturing, a single rust-flecked component can shut down an entire production line. Our American Standard Custom-Made Stainless Steel Sprocket is born from the need to eliminate that risk forever. When you hold one of our custom sprockets, you don't feel the greasy residue of a standard iron part. Instead, you feel the cool, satin-smooth surface of surgical-grade stainless steel. It catches the factory light with a brilliant, clean sheen, signaling to every inspector that your facility operates at the highest tier of mechanical hygiene.

This product was inspired by the engineers who manage heavy-duty bottling and pharmaceutical lines, where traditional sprockets succumb to "pitting" and oxidation within months. Imagine a drive system that operates so silently and cleanly that it feels like a natural extension of your most sophisticated robotics. As the chain rollers meet the sprocket teeth, there is a distinct, rhythmic mechanical harmony—no jarring, no grinding, just the fluid transfer of power. We aren't just selling you a gear; we are selling you the peace of mind that comes from knowing your transmission will never contaminate your product or fail during a critical production window. It is the ultimate investment in the longevity and "health" of your machinery.

Product Features and Highlights

The core of our custom-made sprocket's value lies in our mastery of material science and precision gear geometry, offering four pillars of technical excellence:

Corrosion-Proof Metallurgy: We offer a selection of prime-quality stainless steels. Grade 304 provides excellent resistance to moisture and common detergents, while Grade 316L (Low Carbon) includes molybdenum, making it immune to the "pitting" corrosion caused by salt-water, chlorides, and harsh acidic sanitizers.

Precision CNC Tooth Profiling: Every sprocket is cut using computerized gear hobbing or wire-EDM technology. This ensures that the pressure angle and pitch circle diameter are identical to ANSI standards, reducing the "chordal action" that leads to chain vibration and premature motor failure.

Custom Bore and Keyway Integration: We eliminate the need for secondary onsite machining. Whether you require a splined bore, a tapered bore for a specific bushing, or multiple set-screw keyways, we deliver a "drop-in" component that fits your shaft perfectly from the first installation.

Passivated Surface Treatment: Every stainless sprocket undergoes a specialized nitric acid passivation process. This removes any trace of free iron from the surface and maximizes the natural chromium-oxide protective layer, ensuring your sprocket remains rust-free even under continuous "wash-down" conditions.

Custom Engineering & Made-To-Order Capabilities

No two industrial transmission challenges are identical. Our facility is optimized for "Project-Based" manufacturing, where we treat your technical drawing as a commitment to excellence. Following E-E-A-T principles, we provide a deep level of engineering expertise for your bespoke needs:

Material Selection Consultation: Our engineers analyze your operating environment—including chemical exposure, temperature ranges, and torque loads—to recommend the most cost-effective stainless steel grade.

Specialized Hub Configurations: Beyond standard Type A (Plate), Type B (Single Hub), and Type C (Double Hub), we can manufacture sprockets with extended hubs, offset hubs, or even "split" sprockets for easy installation on long shafts without disassembly.

Heat Treatment for Stainless: While stainless steel is naturally softer than carbon steel, we offer specialized flame or induction hardening for the teeth on certain grades (like 400 series) to significantly improve wear life in abrasive environments.

Rapid Prototyping and Production: We understand that a broken custom sprocket can paralyze your production. Our "Made-To-Order" workflow is designed to move from technical approval to final shipping with industry-leading lead times.

Manufacturing Mastery & Quality Assurance

Quality in the American Standard market is a matter of strict measurement and metallurgical truth. Our manufacturing protocols are designed to exceed North American engineering expectations:

Spectroscopic Material Verification: Every shipment of raw stainless steel plate or bar stock is verified using X-ray fluorescence (XRF) to ensure the alloying elements perfectly match the requested grade (304 vs 316).

Concentricity and Runout Testing: We monitor "total indicated runout" (TIR) on every custom bore. By ensuring the bore is perfectly centered on the pitch circle, we eliminate the uneven chain tension that ruins bearings and gearboxes.

3D Coordinate Measuring Machine (CMM): For high-precision custom teeth profiles, we utilize 3D CMM inspections to verify that every tooth curve follows the mathematical ideal, maximizing power transfer efficiency.

Full Certification Package: Every custom order can be delivered with a comprehensive technical file, including Material Test Certificates (MTC), dimensional reports, and heat-treatment logs for your quality audits.

Versatile Application Dimensions

Our American Standard Stainless Steel Sprockets are the preferred choice for mission-critical applications across a diverse spectrum of high-demand sectors:

Pharmaceutical & Medical Packaging: Used in cleanrooms where non-magnetic, non-rusting components are required to meet FDA and EMA compliance.

Food & Beverage Bottling: Standing up to the continuous high-pressure hot-water wash-downs and corrosive cleaning agents used in milk, juice, and beer production.

Marine & Offshore Engineering: Providing reliable power transmission for winch systems and conveyors exposed to constant salt spray and high-humidity oceanic air.

Chemical & Wastewater Treatment: Driving large-scale filtration and mixing systems where exposure to chlorine, acids, and industrial effluents would destroy a standard iron sprocket.

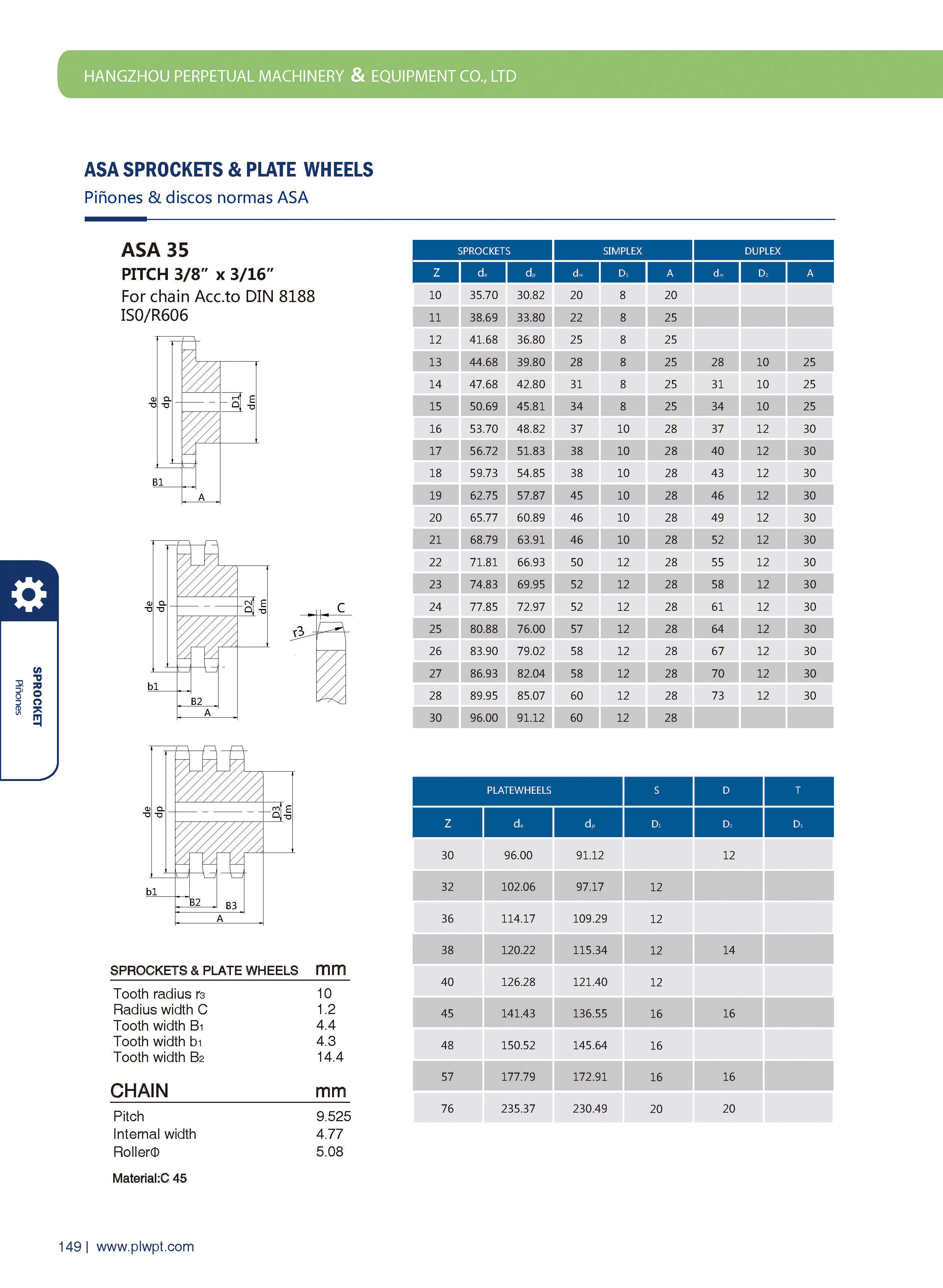

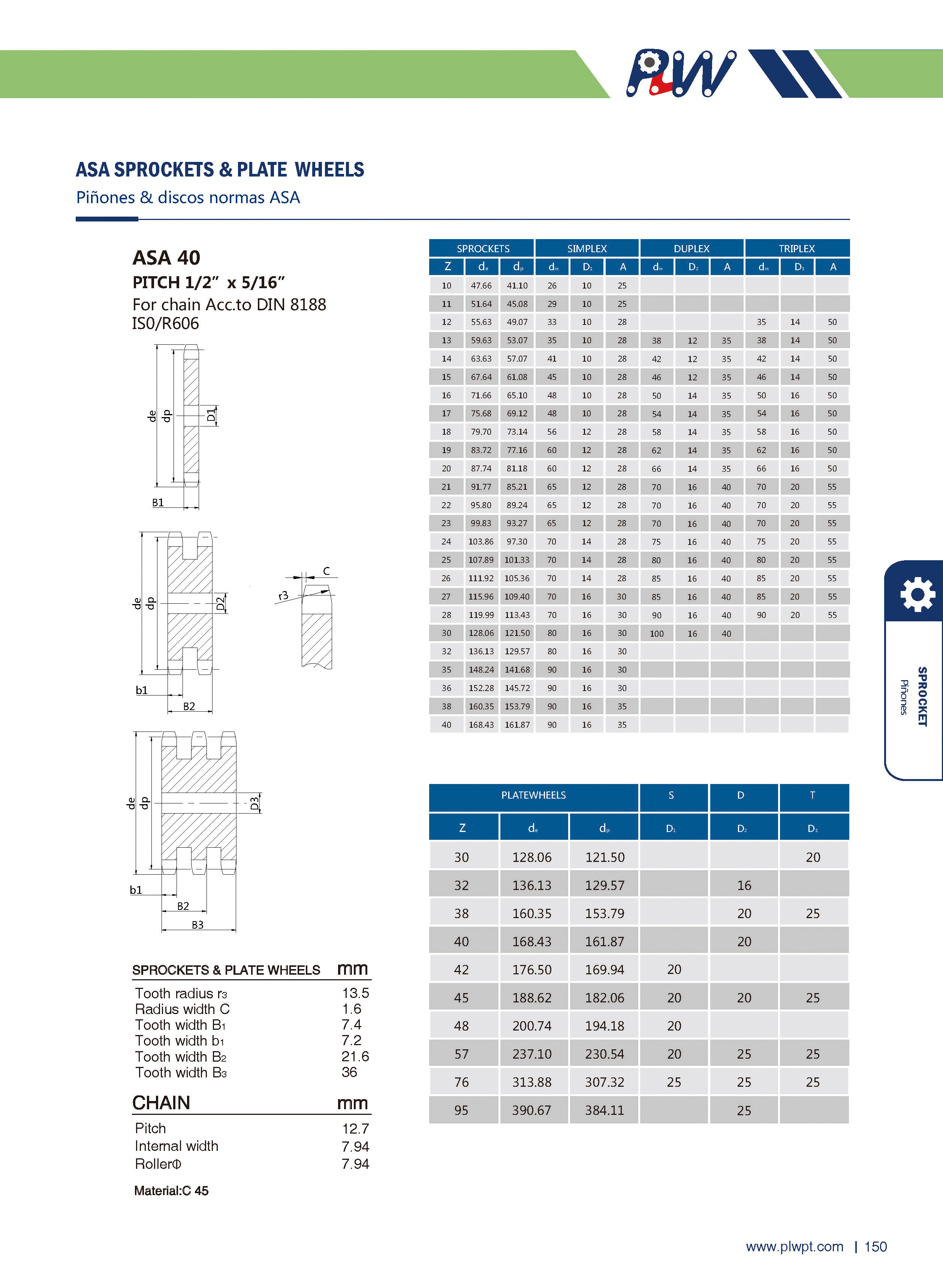

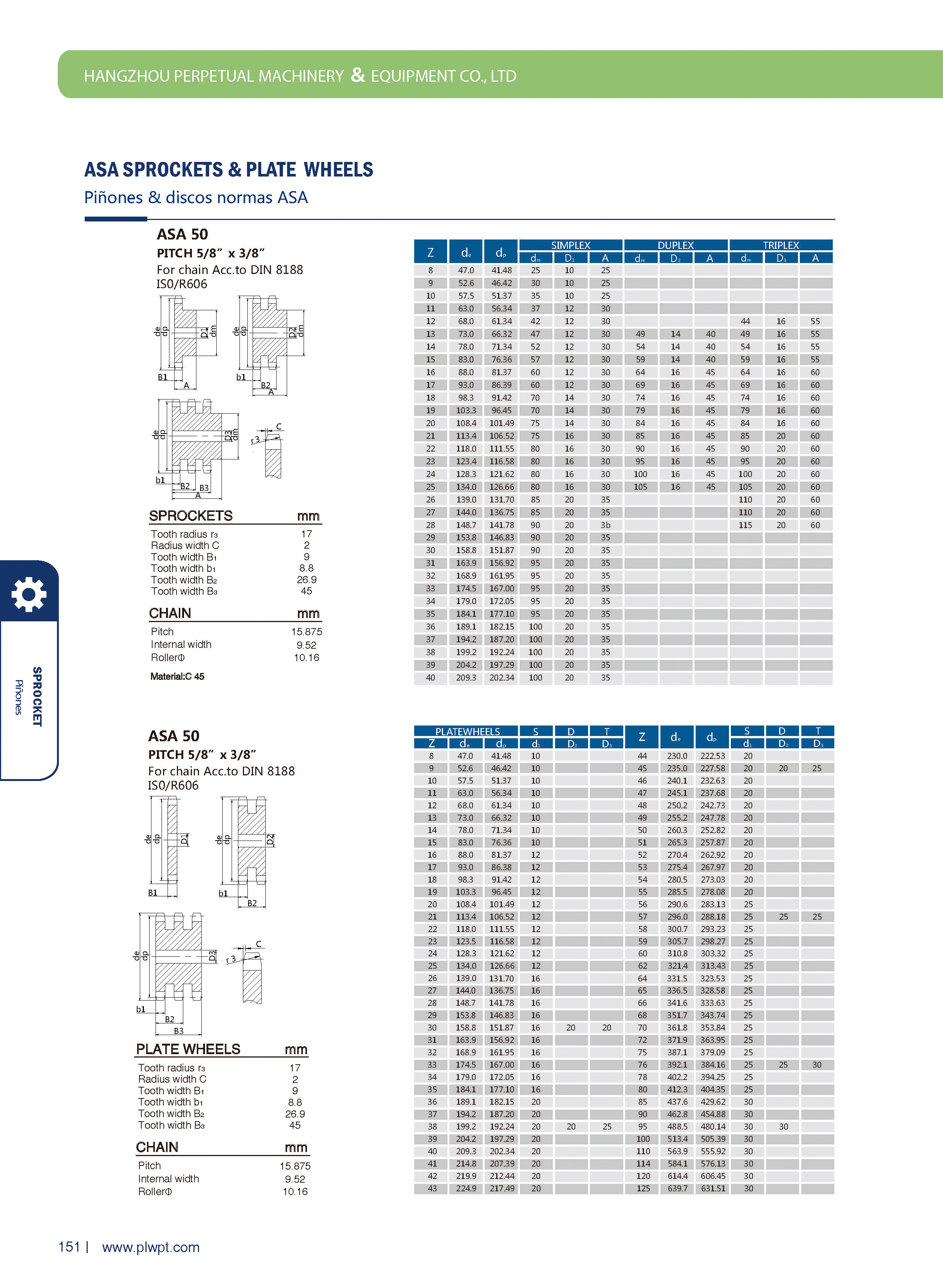

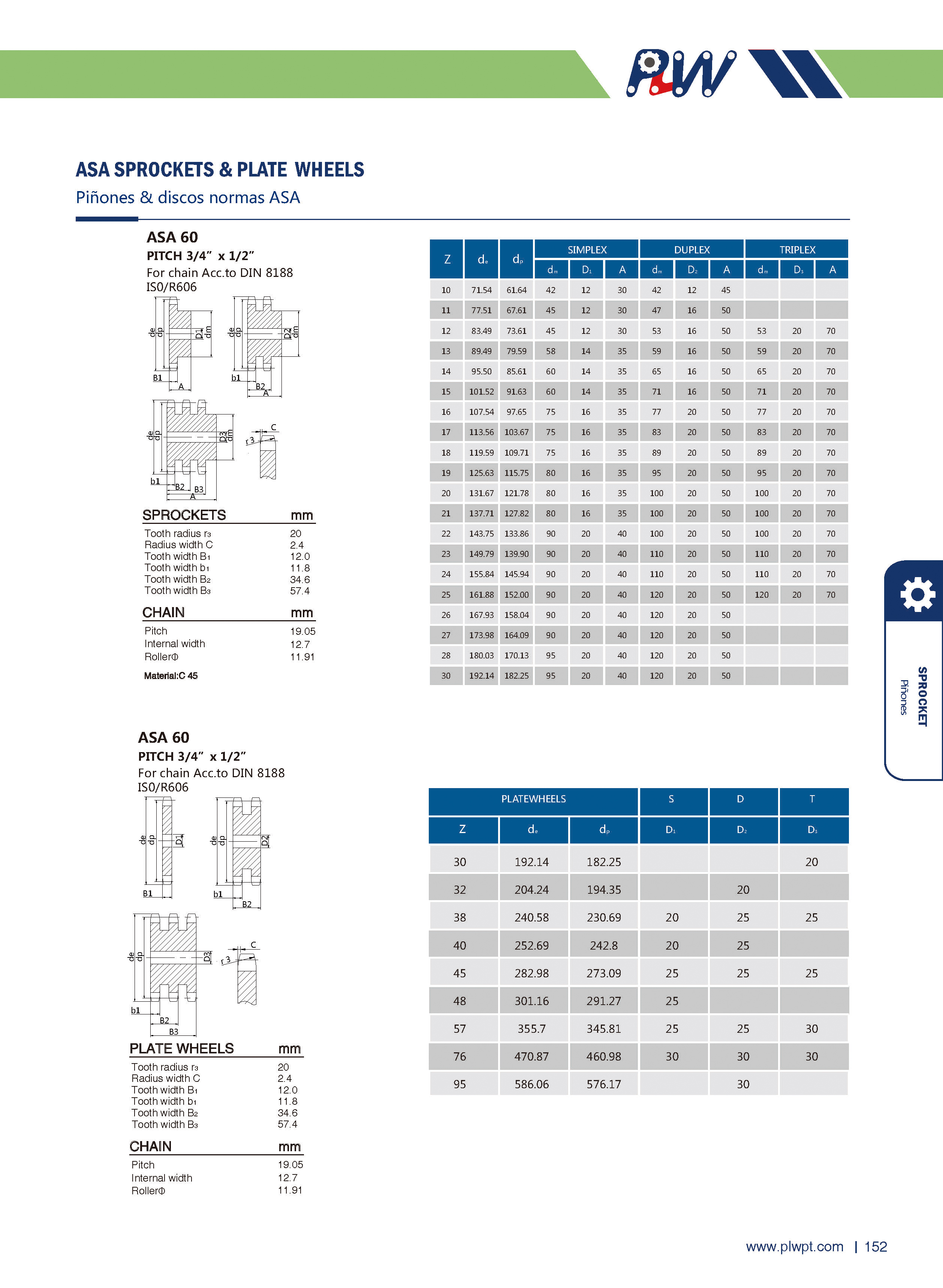

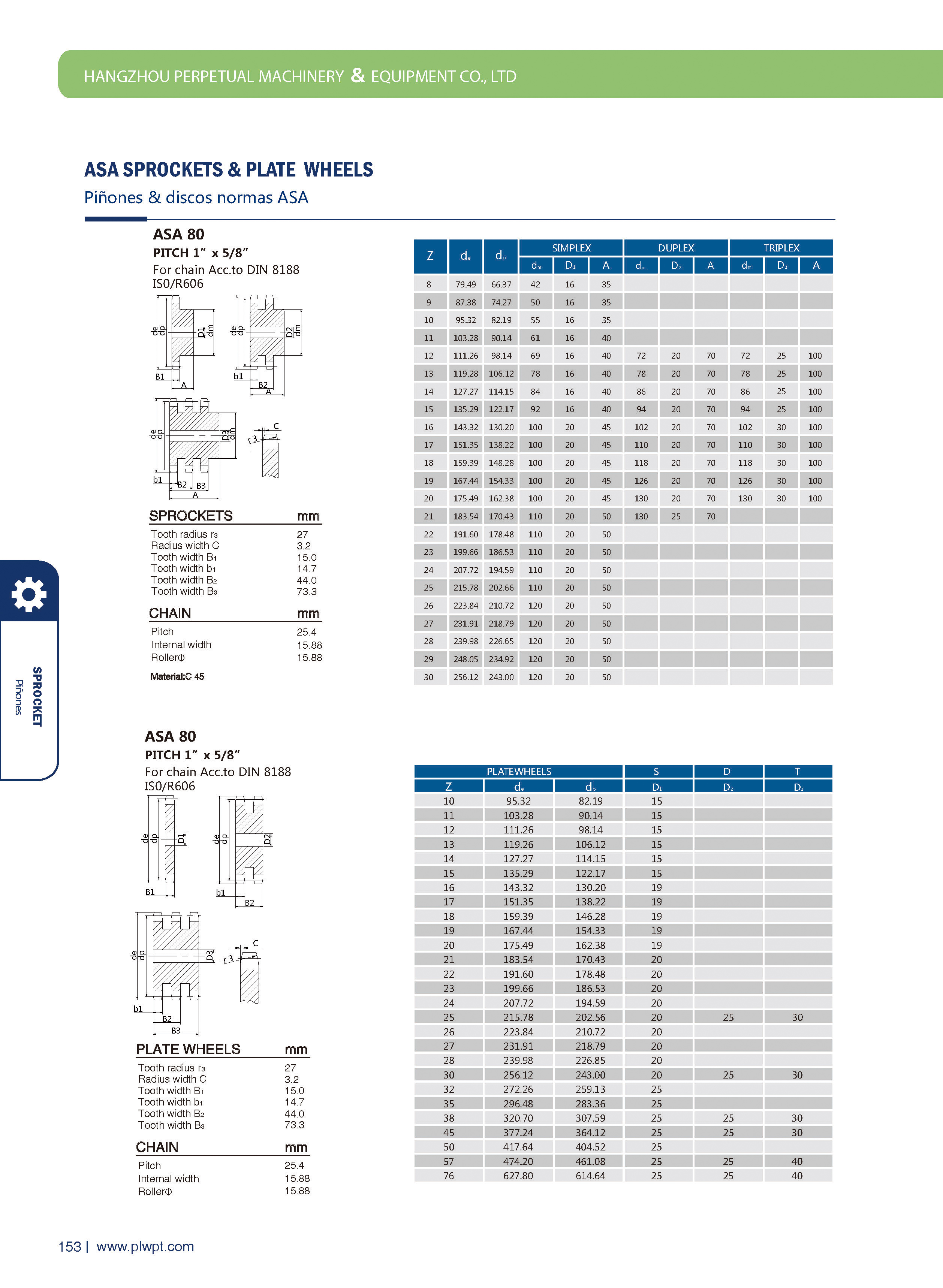

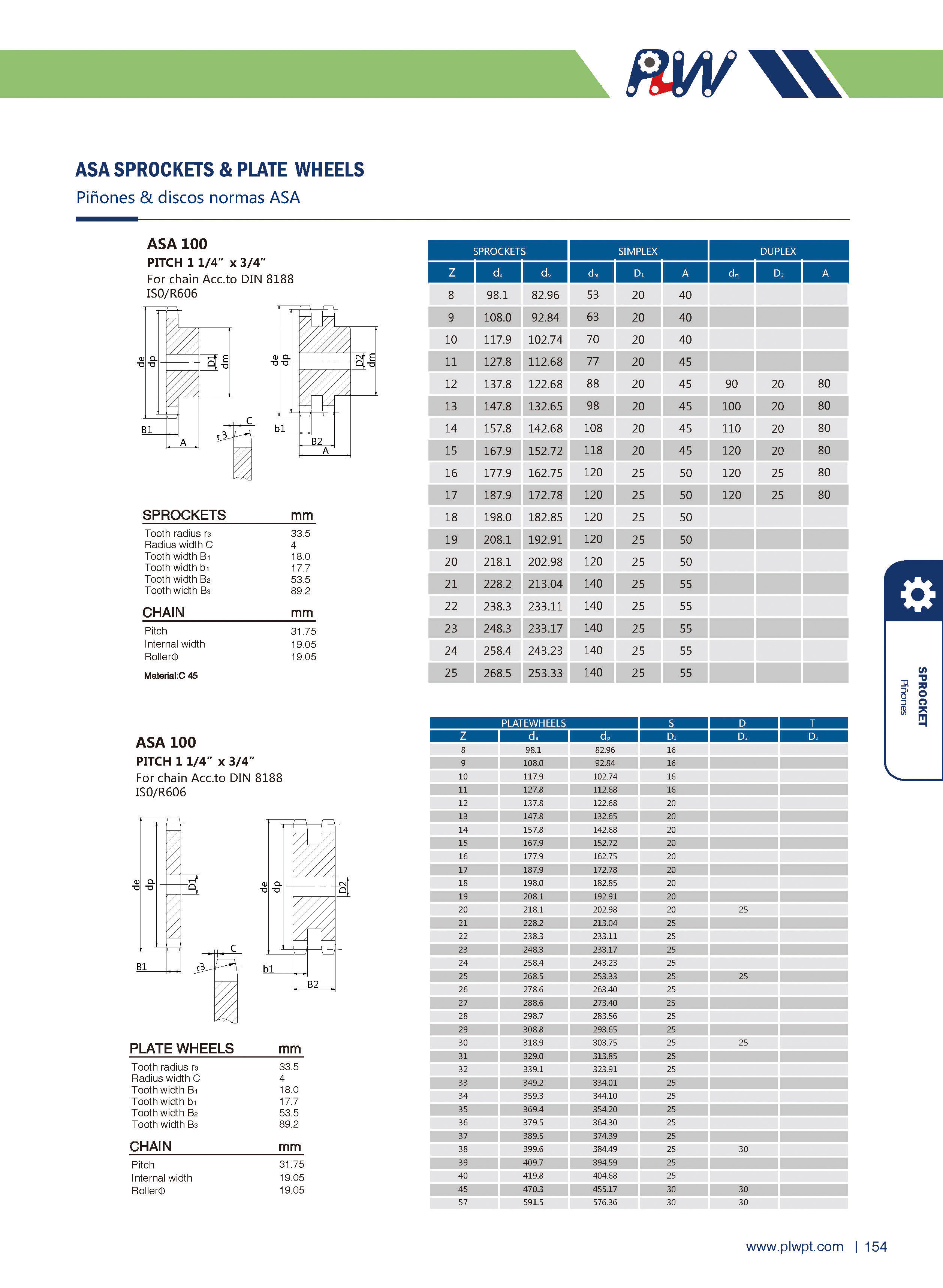

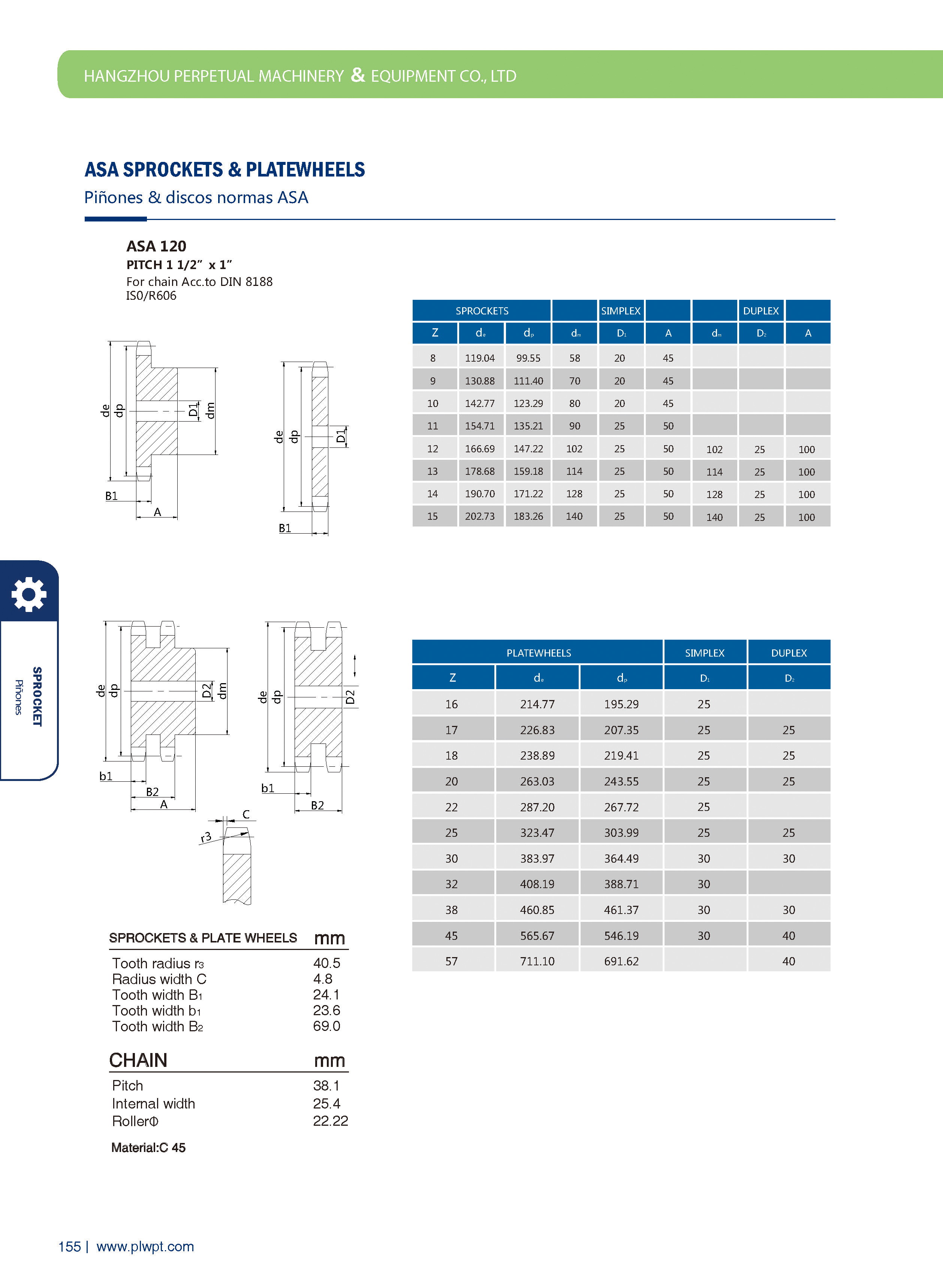

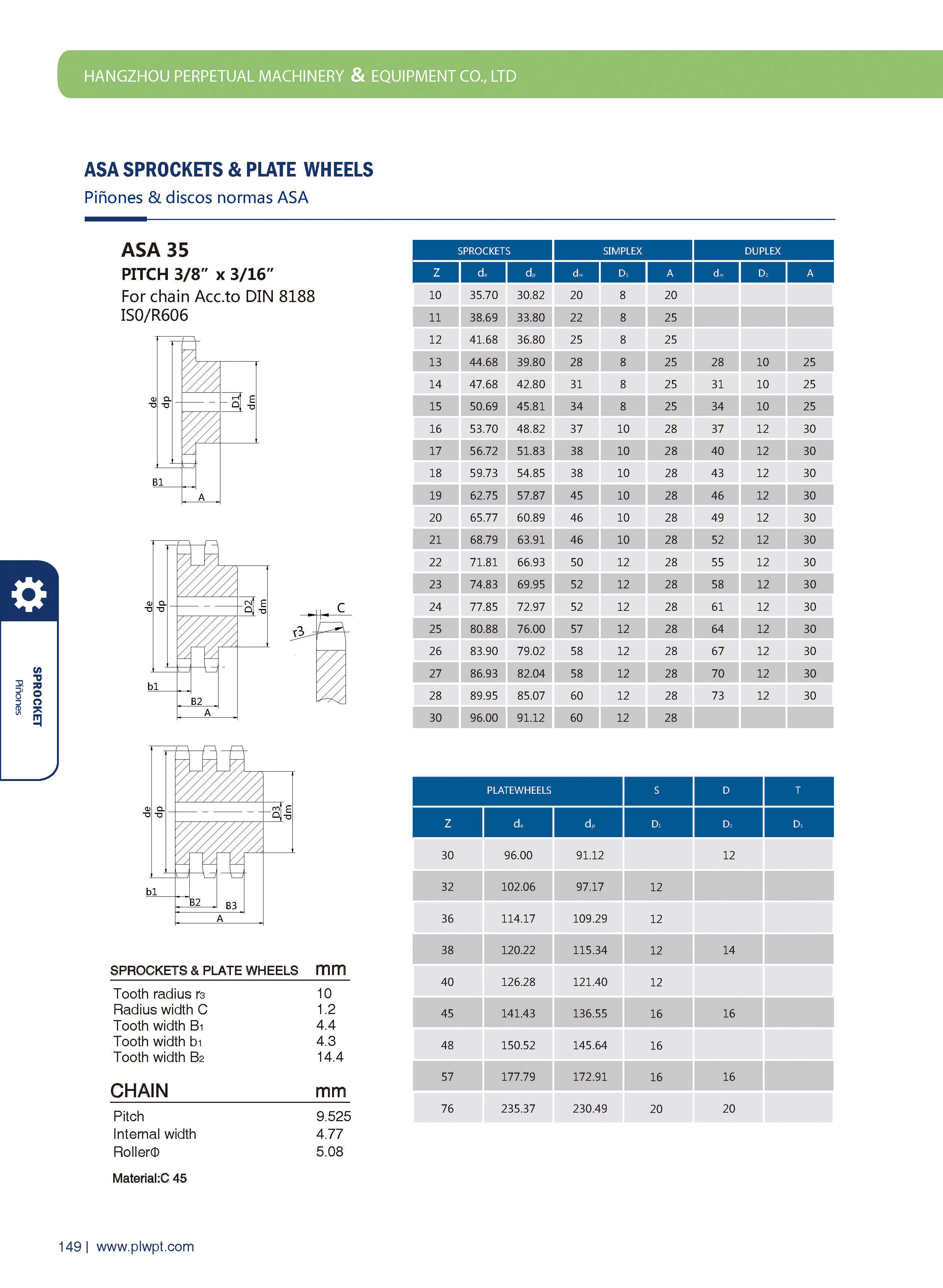

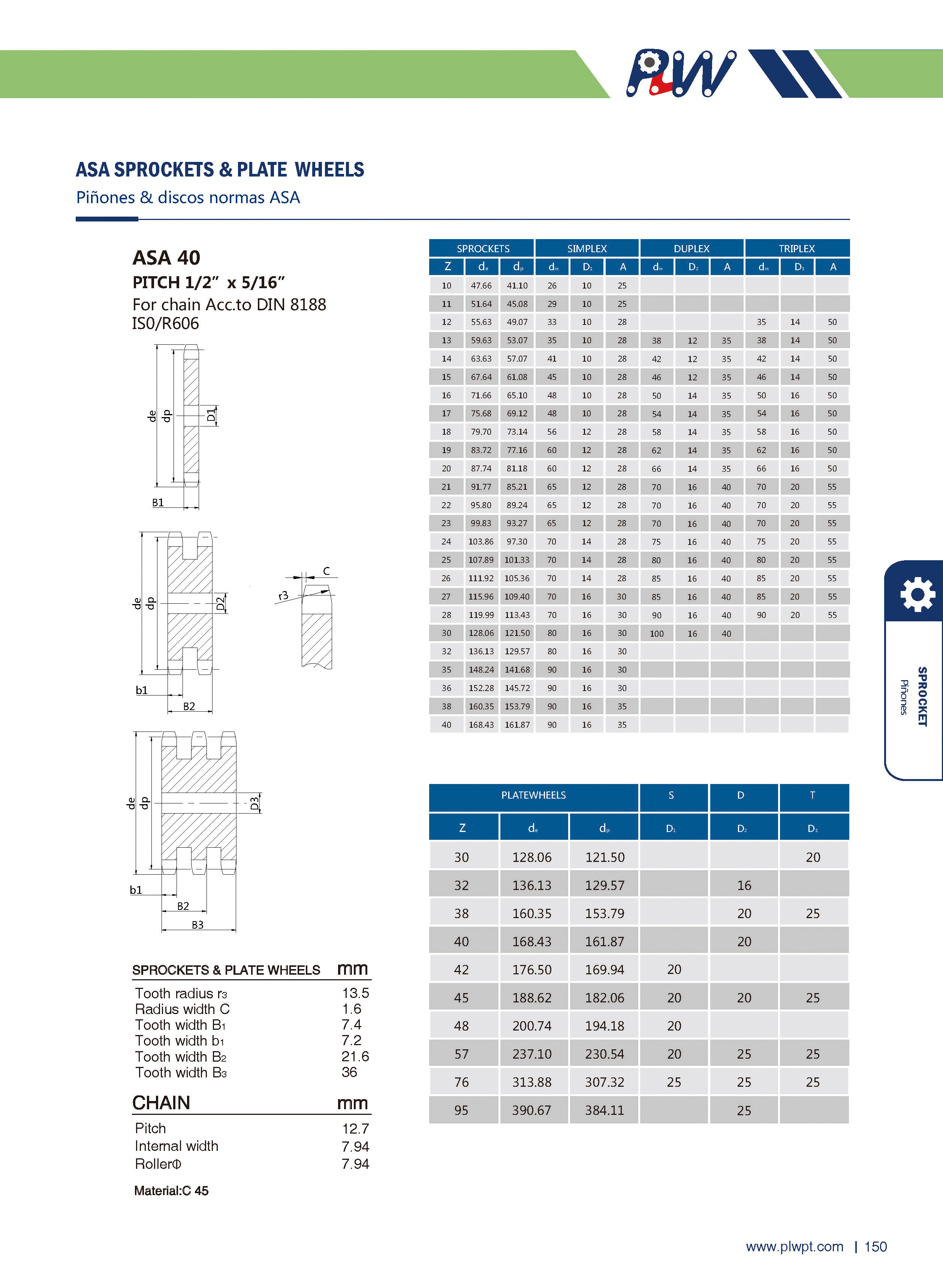

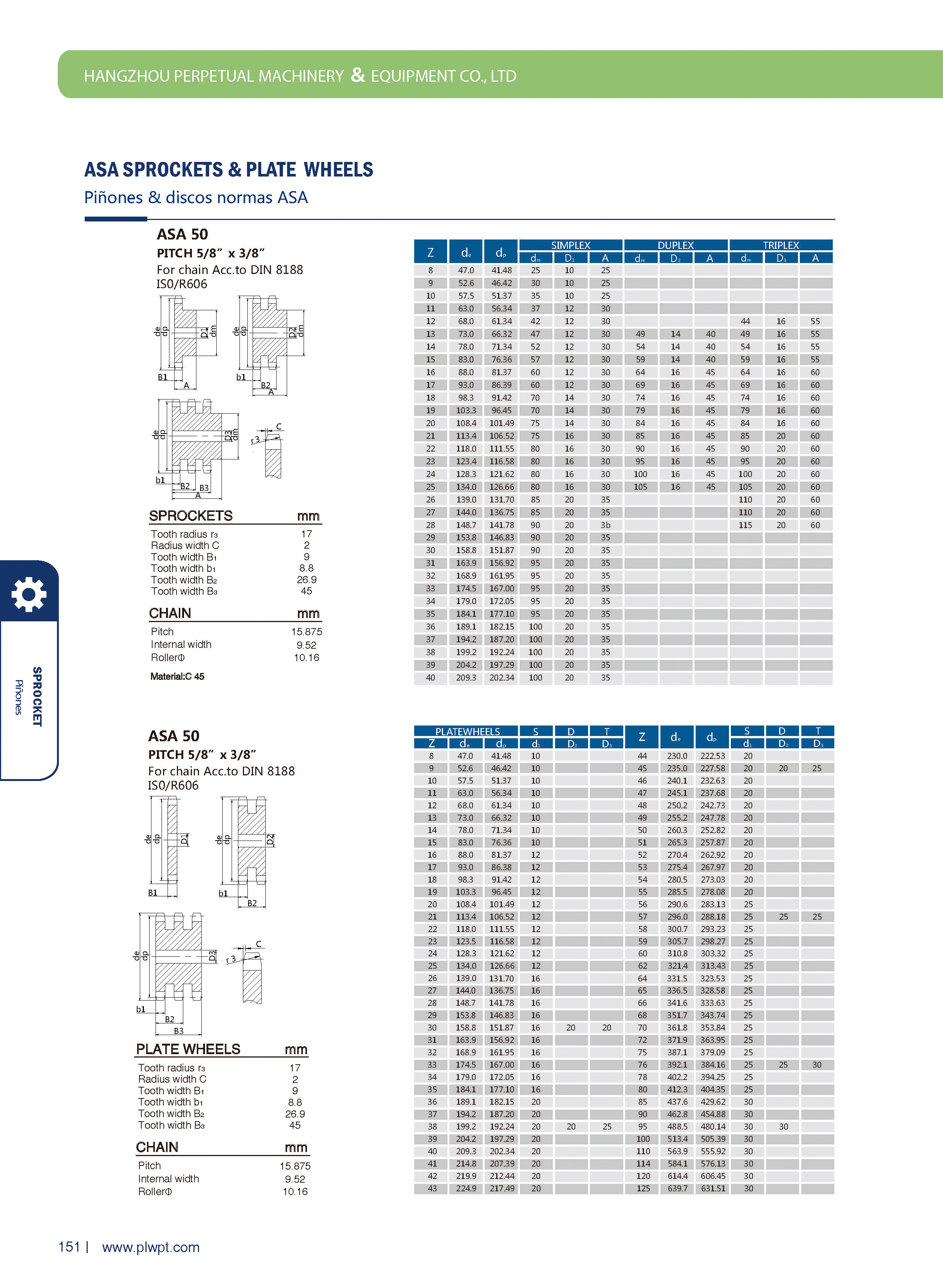

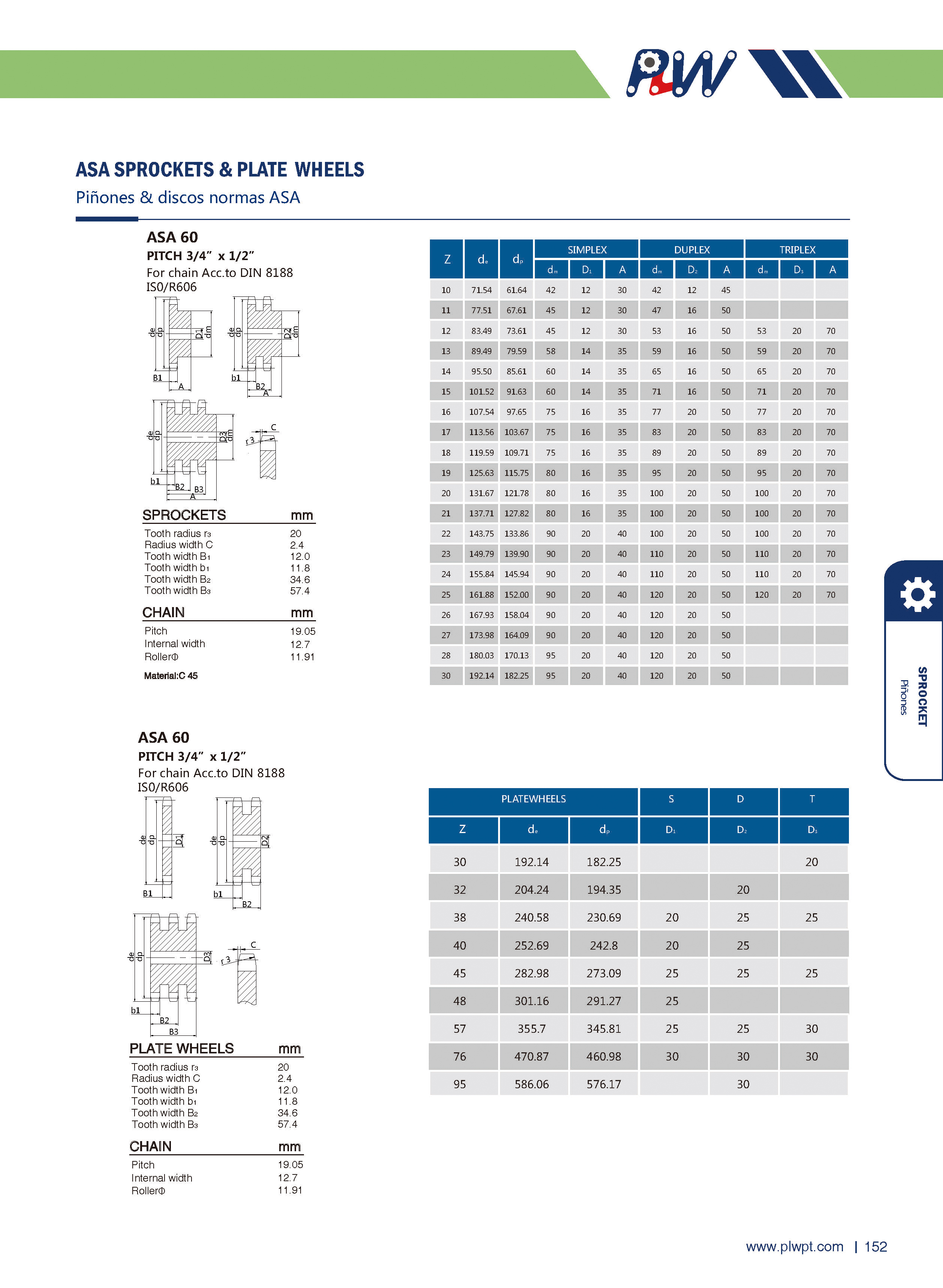

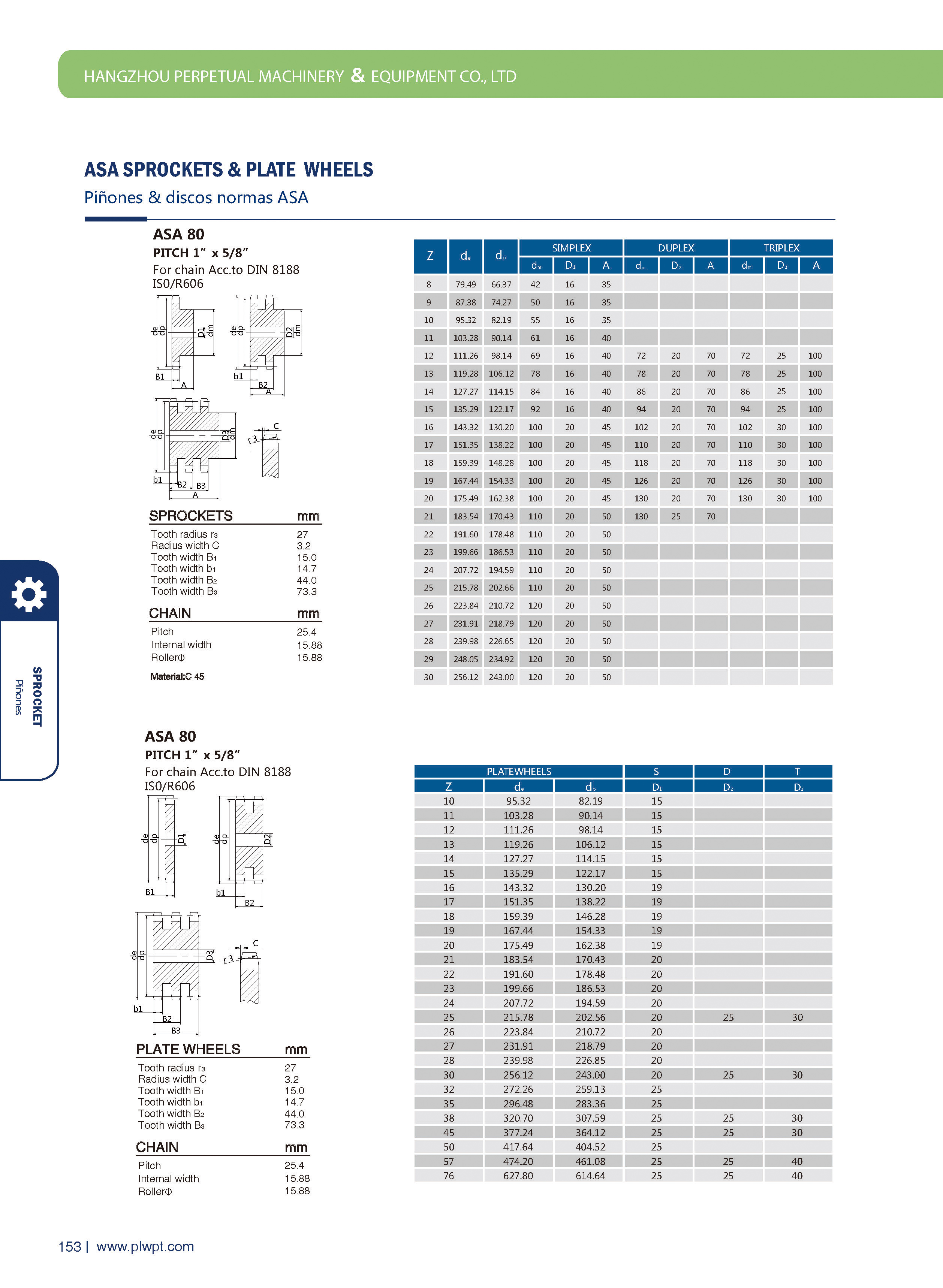

Technical Specifications & Parameter Table

FAQ: Frequently Asked Questions

Q: Can a stainless steel sprocket handle the same torque as a hardened carbon steel sprocket?

A: Standard 304 and 316 stainless steel have a lower surface hardness than induction-hardened carbon steel. However, in corrosive environments, the stainless sprocket is superior because it maintains its profile, whereas carbon steel will pit and wear away rapidly due to rust.

Q: Why should I choose 316L stainless steel over 304?

A: If your equipment is exposed to saltwater, marine air, or acidic chemicals (like those used in meat processing), 316L is essential. Its molybdenum content prevents "pitting" corrosion that can happen even to 304 in those specific conditions.

Q: Do you provide custom tooth profiles for non-standard chains?

A: Yes. As a custom manufacturer, we can hob teeth for any chain pitch, including non-standard or proprietary conveyor chains, provided we have the chain dimensions or a physical sample.

Q: Is it necessary to use a stainless steel chain with a stainless steel sprocket?

A: For maximum corrosion resistance and to prevent "galvanic corrosion," it is highly recommended. Using an iron chain on a stainless sprocket can cause the sprocket to rust where it touches the chain, defeating the purpose of the stainless material.

Would you like me to help you generate a "Custom Sprocket Design Template" to help your customers provide the exact dimensions you need for a quote?

English

Español

العربية

Français

Русский

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

አማርኛ

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Kiswahili

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

Հայերեն

עברית

Latine

Dansk

اردو

Shqip

বাংলা

Hrvatski

Afrikaans

Gaeilge

Eesti keel

Māori

සිංහල

नेपाली

Oʻzbekcha

latviešu

অসমীয়া

Aymara

Azərbaycan dili

Bamanankan

Euskara

Беларуская мова

भोजपुरी