Product Overview

Our Surface Blackening Treatment Sprocket is a premium transmission component crafted for seamless compatibility with standard chains (roller chains, silent chains, etc.). Manufactured with alloy steel or stainless steel and adhering to ISO 9001:2008, IATF 16949:2009, and ISO 14001:2004 certifications, this standard sprocket features a professional blackening process that forms a dense Fe₃O₄ film on the surface. Designed for mechanical transmission and material conveying, our corrosion-resistant sprocket delivers exceptional wear resistance, dimensional stability, and cost-effectiveness, making it ideal for global industrial and agricultural applications.

Core Selling Points & Benefits

Enhanced Corrosion & Rust Resistance

The blackening treatment creates a protective oxide film that isolates the sprocket substrate from air and moisture. When combined with oil immersion, it extends rust-free service life in dry/mildly humid environments, reducing transmission jamming risks.

Improved Surface Hardness & Wear Resistance

With a surface hardness of 200-300HV (higher than the 180HV substrate), the wear-resistant sprocket minimizes friction between teeth and chain rollers, reducing metal debris and extending the lifespan of both sprocket and chain.

Precision Dimensional Stability

The ultra-thin blackened film (0.5-1.5 microns) preserves the sprocket’s original dimensions and tooth profile accuracy, ensuring seamless meshing with chains in high-precision systems like machine tools and conveyors.

Cost-Effective & Scalable Production

Compared to electroplating or chrome plating, blackening offers lower equipment investment and processing costs. The simple process (pre-treatment → blackening → post-treatment) supports mass production, ideal for small-to-medium enterprises.

Superior Lubricity & Noise Reduction

The microporous oxide film adsorbs lubricants, forming an oil film that lowers friction coefficients, reduces power loss, and minimizes meshing noise for smoother transmission.

Technical Specifications

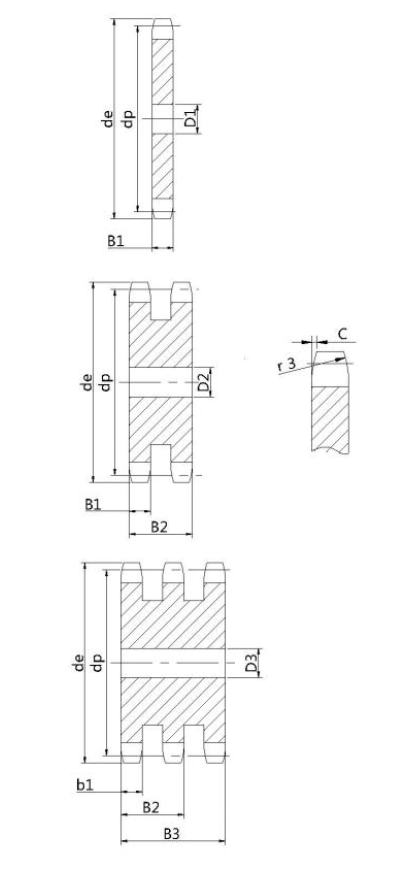

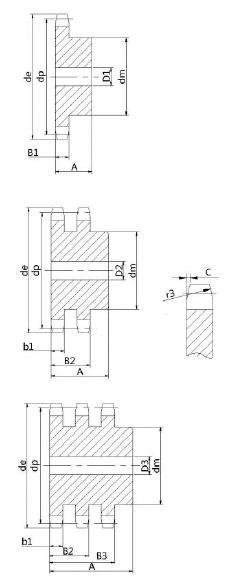

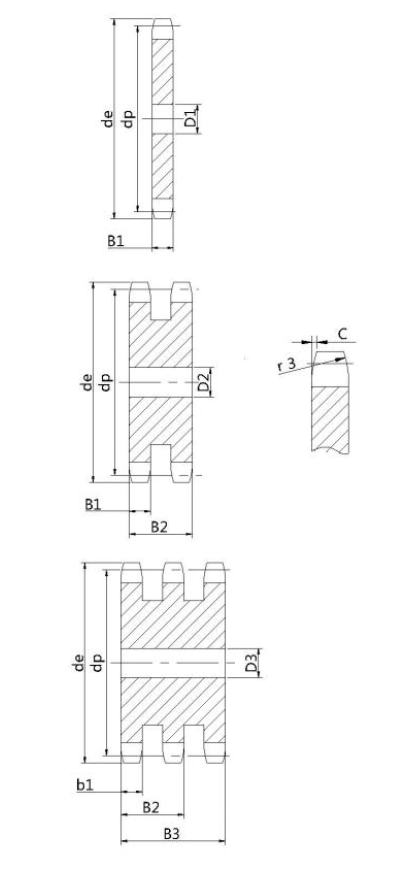

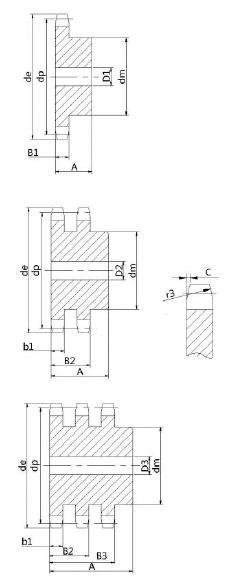

Type | P | Roller | B1 | b1 | B2-b1 | Intermal width |

04C | 6.35 | 3.3 | 2.7 | 2.5 | 6.4 | 3.18 |

04B | 6 | 4 | 2.3 |

|

| 2.8 |

05B | 8 | 5 | 2.6 | 2.4 | 5.64 | 3 |

06C | 9.525 | 5.08 | 4.2 | 4 | 10.13 | 4.77 |

06B | 9.525 | 6.35 | 5.2 | 5 | 10.24 | 5.72 |

08A | 12.7 | 7.95 | 7.2 | 6.9 | 14.38 | 7.85 |

08B | 12.7 | 8.51 | 7.1 | 6.8 | 13.92 | 7.75 |

10A | 15.875 | 10.16 | 8.7 | 8.4 | 18.11 | 9.4 |

10B | 15.875 | 10.16 | 8.9 | 8.6 | 16.59 | 9.65 |

12A | 19.05 | 11.91 | 11.7 | 11.3 | 22.78 | 12.57 |

12B | 19.05 | 12.07 | 10.8 | 10.5 | 19.46 | 11.68 |

16A | 25.4 | 15.88 | 14.6 | 14.1 | 29.29 | 15.75 |

16B | 25.4 | 15.88 | 15.9 | 15.4 | 31.88 | 17.02 |

20A | 31.75 | 19.05 | 17.6 | 17 | 35.76 | 18.9 |

20B | 31.75 | 19.05 | 18.3 | 17.7 | 36.45 | 19.56 |

24A | 38.1 | 22.23 | 23.5 | 22.7 | 45.44 | 25.22 |

24B | 38.1 | 25.4 | 23.7 | 22.9 | 48.36 | 25.4 |

28A | 44.45 | 25.4 | 24.5 | 22.7 | 48.87 | 25.22 |

28B | 44.45 | 27.94 | 30.3 | 28.5 | 59.56 | 30.99 |

32A | 50.8 | 28.58 | 29.4 | 28.4 | 58.55 | 31.55 |

32B | 50.8 | 29.21 | 28.9 | 27.9 | 58.55 | 30.99 |

Application Scenarios

Machine Tools: High-precision transmission systems benefit from the sprocket’s dimensional stability and low friction.

Agricultural Machinery: Tractors, harvesters, and irrigation equipment use the corrosion-resistant design to withstand farm environments.

Conveyor Systems: Logistics and manufacturing lines rely on the sprocket’s wear resistance for continuous operation.

High-Temperature/Corrosive Environments: Suitable for moderate harsh conditions where cost-effectiveness and durability are critical.

FAQ

What is the blackening treatment process?

It’s a chemical reaction forming a Fe₃O₄ film on the surface, followed by optional oil immersion for enhanced protection—eco-friendly and cost-effective.

Can this sprocket work with stainless steel chains?

Yes! It is compatible with all standard chains (roller, silent, leaf chains) and works seamlessly with stainless steel or carbon steel chains.

What is the service life in humid environments?

With regular lubrication, it lasts 2-3 years in mildly humid conditions; for high-humidity areas, we recommend stainless steel material.

Do you offer custom sprocket sizes?

Absolutely! We provide custom designs based on your machinery’s specifications, including non-standard pitches and tooth counts.

Call to Action

Elevate your transmission system with our Chinese High-Quality Blackening Treatment Sprocket—the perfect balance of performance, cost, and precision. Request a free sample, get a personalized quote, or consult our engineers for compatibility advice today. With fast delivery, ISO-certified quality, and competitive pricing, we’re your trusted partner for reliable mechanical transmission sprockets. Don’t wait—secure your sprockets now and experience long-lasting efficiency!

English

Español

العربية

Français

Русский

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

አማርኛ

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Kiswahili

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

Հայերեն

עברית

Latine

Dansk

اردو

Shqip

বাংলা

Hrvatski

Afrikaans

Gaeilge

Eesti keel

Māori

සිංහල

नेपाली

Oʻzbekcha

latviešu

অসমীয়া

Aymara

Azərbaycan dili

Bamanankan

Euskara

Беларуская мова

भोजपुरी