Corrosion Resistant/Zinc-Plated Chain (25ZP, 35ZP, 41ZP, 50ZP)

Galvanized chains refer to transmission or conveying chains with their surfaces treated by galvanization processes. They are widely used in machinery manufacturing, logistics transportation, agricultural equipment, outdoor facilities, and other fields. Their core feature is that the galvanized layer provides excellent corrosion resistance while retaining the chain’s inherent mechanical properties and transmission stability. Below is a detailed introduction covering process principles, types, performance advantages, application scenarios, and maintenance key points:

I. Principle of Galvanization Process

Galvanization is a common metal surface anti-corrosion treatment technology. It forms a uniform, dense zinc coating on the chain surface, utilizing zinc’s sacrificial anode protection (zinc corrodes preferentially over iron) and physical isolation effect to block contact between the chain substrate (usually carbon steel) and air, moisture, or corrosive media. This delays chain rusting and extends service life.

A typical galvanization process for chains includes:

Pretreatment: Removal of oil, rust, and scale from the chain surface (e.g., pickling, alkaline cleaning, grinding) to ensure a clean surface, providing a good foundation for coating adhesion.

Galvanization Treatment: Deposition of a zinc layer on the chain surface via electroplating or hot-dip galvanization.

Post-treatment: Including passivation (forming a passivation film to enhance corrosion resistance), cleaning, and drying. In some cases, oiling or sealing is added to further improve protective effects.

II. Main Types of Galvanized Chains

Based on different galvanization processes, common galvanized chains are categorized into two types:

1. Electro-Galvanized Chains

Process Characteristics: Zinc ions are deposited onto the chain surface via electrolysis, forming a uniform zinc coating with a relatively thin thickness (typically 5-20 microns).

Advantages: The coating is fine, smooth, and uniform in appearance (silver-white), with minimal impact on dimensional accuracy. Suitable for scenarios requiring high 外观 and size precision.

Limitations: The thin coating offers weaker corrosion resistance compared to hot-dip galvanization, with limited protection in long-term outdoor or high-humidity environments.

2. Hot-Dip Galvanized Chains

Process Characteristics: Chains are immersed in molten zinc (approximately 450°C), forming a zinc-iron alloy layer and a pure zinc layer on the surface, with a thicker coating (typically 50-150 microns).

Advantages: The coating adheres firmly to the substrate, providing strong corrosion resistance and adapting to harsh environments (e.g., outdoor, humid, dusty, or mildly corrosive scenarios).

Limitations: The thick coating may slightly affect the chain’s fitting precision; the surface appears slightly rough with a silver-gray color and possible zinc spangles.

III. Core Performance Advantages of Galvanized Chains

1. Excellent Corrosion Resistance and Rust Resistance

The galvanized layer effectively blocks moisture, oxygen, and contaminants from eroding the chain substrate. Especially in humid, rainy, high-humidity, or mildly acidic/alkaline environments, it significantly delays rusting and aging, extending service life by 3-5 times or more compared to untreated carbon steel chains.

2. Retains Original Mechanical Properties

Galvanization does not significantly affect the chain’s base material strength, hardness, or toughness. Core mechanical properties such as tensile strength, wear resistance, and transmission precision are preserved, ensuring stable and reliable performance in transmission or conveying processes.

3. Wide Environmental Adaptability and Scenario Compatibility

Outdoor Scenarios: Agricultural machinery (harvesters, seeders), outdoor conveying equipment, construction machinery, etc., resisting corrosion from wind, rain, and weather.

Humid Scenarios: Food processing (non-direct food contact conveying links), aquaculture equipment, sewage treatment equipment, etc., resisting moisture erosion.

Mildly Corrosive Scenarios: Auxiliary chemical equipment, mining conveying systems, coastal area equipment, etc., tolerating salt spray or mild chemical corrosion.

4. Clean Appearance with Both Protection and Basic Decorativeness

The galvanized layer has a uniform silver-white or silver-gray surface, appearing neat and consistent. It can be used as an exposed component without additional painting, suitable for equipment with basic 外观 requirements (e.g., exposed transmission parts of logistics conveyor lines or automated equipment).

5. Low Maintenance Costs and Easy Usage

Galvanized chains require simple daily maintenance: no frequent rust removal or painting is needed, and only regular lubrication is sufficient to maintain good performance, reducing long-term maintenance labor and material costs.

IV. Applicable Scenarios and Typical Applications

Galvanized chains play a vital role in multiple fields due to their corrosion resistance and reliability:

Agricultural Machinery: Tractor transmission chains, harvester conveying chains, adapting to humid farmland and soil environments.

Logistics and Conveying: Warehouse shelf conveyor chains, sorter chains, especially in humid warehouses or outdoor transfer stations.

Outdoor Facilities: Sunshade awning drive chains, gate opening/closing chains, billboard rotation chains, resisting outdoor climate erosion.

Light Industry Equipment: Laundry equipment drive chains, packaging machinery conveying chains, adapting to humid or moisture-rich environments.

Mining and Construction: Small mining conveyor chains, auxiliary chains for construction elevators, resisting dust and moisture.

V. Usage and Maintenance Notes

Avoid Severe Impact or Overloading: Although the galvanized layer is durable, severe impact may cause coating peeling, affecting protection. Always adhere to the chain’s rated load requirements.

Regular Lubrication: The galvanized layer is not self-lubricating. Regularly apply suitable lubricants (e.g., mineral oil, grease) to reduce wear on chain joints; lubricants also help isolate moisture.

Avoid Long-Term Contact with Strong Corrosives: Galvanized chains are only suitable for mildly corrosive environments. For contact with strong acids, alkalis, or high-concentration salt spray, choose higher-grade anti-corrosion treatments (e.g., stainless steel chains or plastic-coated chains).

Store in Dry Environments: For long-term storage, avoid damp, dark environments. Apply anti-rust oil or wrap in moisture-proof paper to prevent localized coating rusting.

Regularly Inspect Coating Integrity: If coating damage or peeling is found during use, repair promptly (e.g., apply anti-rust paint) to prevent rapid rusting of exposed substrates

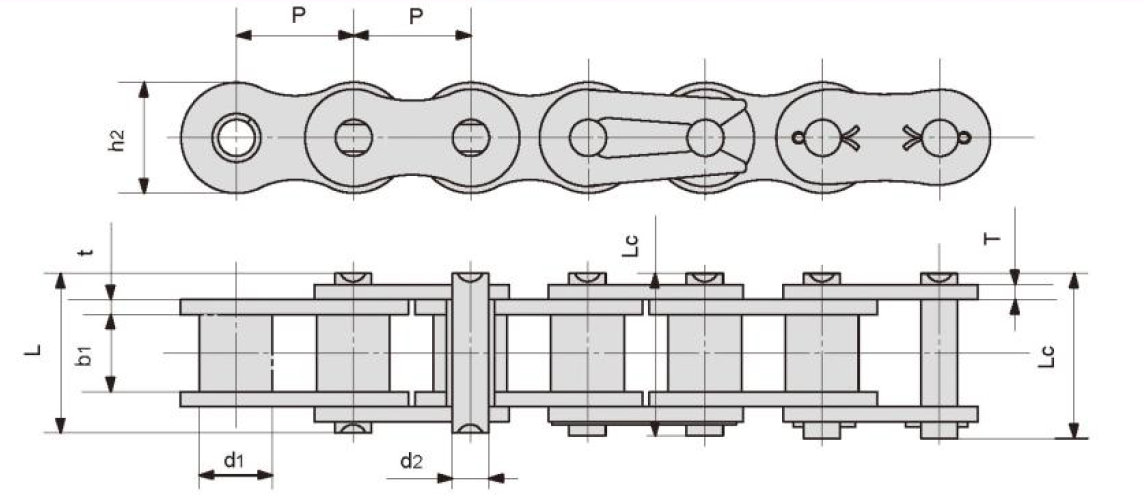

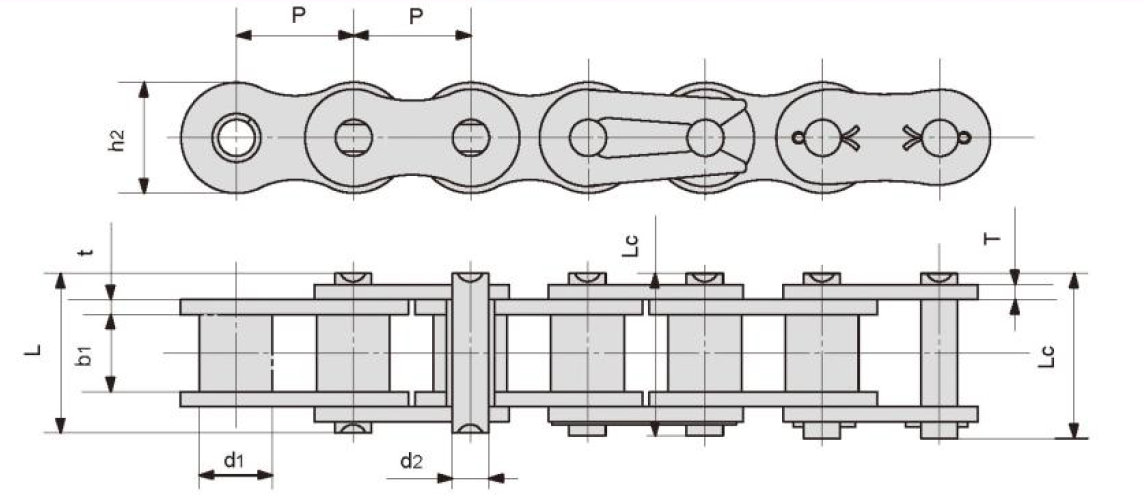

| CHAIN NO. | Pitch | Roller

diameter | Width

batween

inner plates | Pin

diameter | Pin length | Inner

plate

depth | Plate

thickness | Breaking load | Weight

per meter |

| Cadena no | Paso | Diámetro

rodillo | Ancho

interior | Diametro

pasador | Longitud pasador | Altura

placas | Ancho

placas | Carga rotura | Peso

por

metro |

| P | d1

max | b1

min | d2

max | L

max | Lc

max | h2

max | t/T

max | Q | q |

| mm | mm | mm | mm | mm | mm | mm | mm | kN/LB | kg/m |

| *25ZP | 6.350 | 3.30 | 3.18 | 2.31 | 7.90 | 8.40 | 6.00 | 0.80 | 3.50/795 | 0.15 |

| *35ZP | 9.525 | 5.08 | 4.77 | 3.58 | 12.40 | 13.17 | 9.00 | 1.30 | 7.90/1795 | 0.33 |

| 41ZP | 12.700 | 7.77 | 6.25 | 3.58 | 13.75 | 15.00 | 9.91 | 1.30 | 6.67/1516 | 0.41 |

| 40ZP | 12.700 | 7.95 | 7.85 | 3.96 | 16.60 | 17.80 | 12.00 | 1.50 | 14.10/3205 | 0.62 |

| 50ZP | 15.875 | 10.16 | 9.40 | 5.08 | 20.70 | 22.20 | 15.09 | 2.03 | 22.20/5045 | 1.02 |

| 60ZP | 19.050 | 11.91 | 12.57 | 5.94 | 25.90 | 27.70 | 18.00 | 2.42 | 31.80/7227 | 1.50 |

| 80ZP | 25.400 | 15.88 | 15.75 | 7.92 | 32.70 | 35.00 | 24.00 | 3.25 | 56.70/12886 | 2.60 |

| 100ZP | 31.750 | 19.05 | 18.90 | 9.53 | 40.40 | 44.70 | 30.00 | 4.00 | 88.50/20114 | 3.91 |

| 120ZP | 38.100 | 22.23 | 25.22 | 11.10 | 50.30 | 54.30 | 35.70 | 4.80 | 127.00/28864 | 5.62 |

| 140ZP | 44.450 | 25.40 | 25.22 | 12.70 | 54.40 | 59.00 | 41.00 | 5.60 | 172.40/39182 | 7.50 |

| 160ZP | 50.800 | 28.58 | 31.55 | 14.27 | 64.80 | 69.60 | 47.80 | 6.40 | 226.80/51545 | 10.10 |

| 04BZP | 6.000 | 4.00 | 2.80 | 1.85 | 6.80 | 7.80 | 5.00 | 0.60 | 3.00/682 | 0.11 |

| 05BZP | 8.000 | 5.00 | 3.00 | 2.31 | 8.20 | 8.90 | 7.10 | 0.80 | 5.00/1136 | 0.20 |

| #06BZP | 9.525 | 6.35 | 5.72 | 3.28 | 13.15 | 14.10 | 8.20 | 1.30 | 9.00/2045 | 0.41 |

| 08BZP | 12.700 | 8.51 | 7.75 | 4.45 | 16.70 | 18.20 | 11.80 | 1.60 | 18.00/4091 | 0.69 |

| 10BZP | 15.875 | 10.16 | 9.65 | 5.08 | 19.50 | 20.90 | 14.70 | 1.70 | 22.40/5091 | 0.93 |

| 12BZP | 19.050 | 12.07 | 11.68 | 5.72 | 22.50 | 24.20 | 16.00 | 1.85 | 29.00/6591 | 1.15 |

| 16BZP | 25.400 | 15.88 | 17.02 | 8.28 | 36.10 | 37.40 | 21.00 | 4.15/3.1 | 60.00/13636 | 2.71 |

| 20BZP | 31.750 | 19.05 | 19.56 | 10.19 | 41.30 | 45.00 | 26.40 | 4.5/3.5 | 95.00/21591 | 3.70 |

| 24BZP | 38.100 | 25.40 | 25.40 | 14.63 | 53.40 | 57.80 | 33.20 | 6.0/4.8 | 160.0/36364 | 7.10 |

| 28BZP | 44.450 | 27.94 | 30.99 | 15.90 | 65.10 | 69.50 | 36.70 | 7.5/6.0 | 200.0/45455 | 8.50 |

| 32BZP | 50.800 | 29.21 | 30.99 | 17.81 | 66.00 | 71.00 | 42.00 | 7.0/6.0 | 250.0/56818 | 10.25 |

English

Español

العربية

Français

Русский

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

አማርኛ

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Kiswahili

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

Հայերեն

עברית

Latine

Dansk

اردو

Shqip

বাংলা

Hrvatski

Afrikaans

Gaeilge

Eesti keel

Māori

සිංහල

नेपाली

Oʻzbekcha

latviešu

অসমীয়া

Aymara

Azərbaycan dili

Bamanankan

Euskara

Беларуская мова

भोजपुरी