Sprocket.pdf

Sprocket.pdf

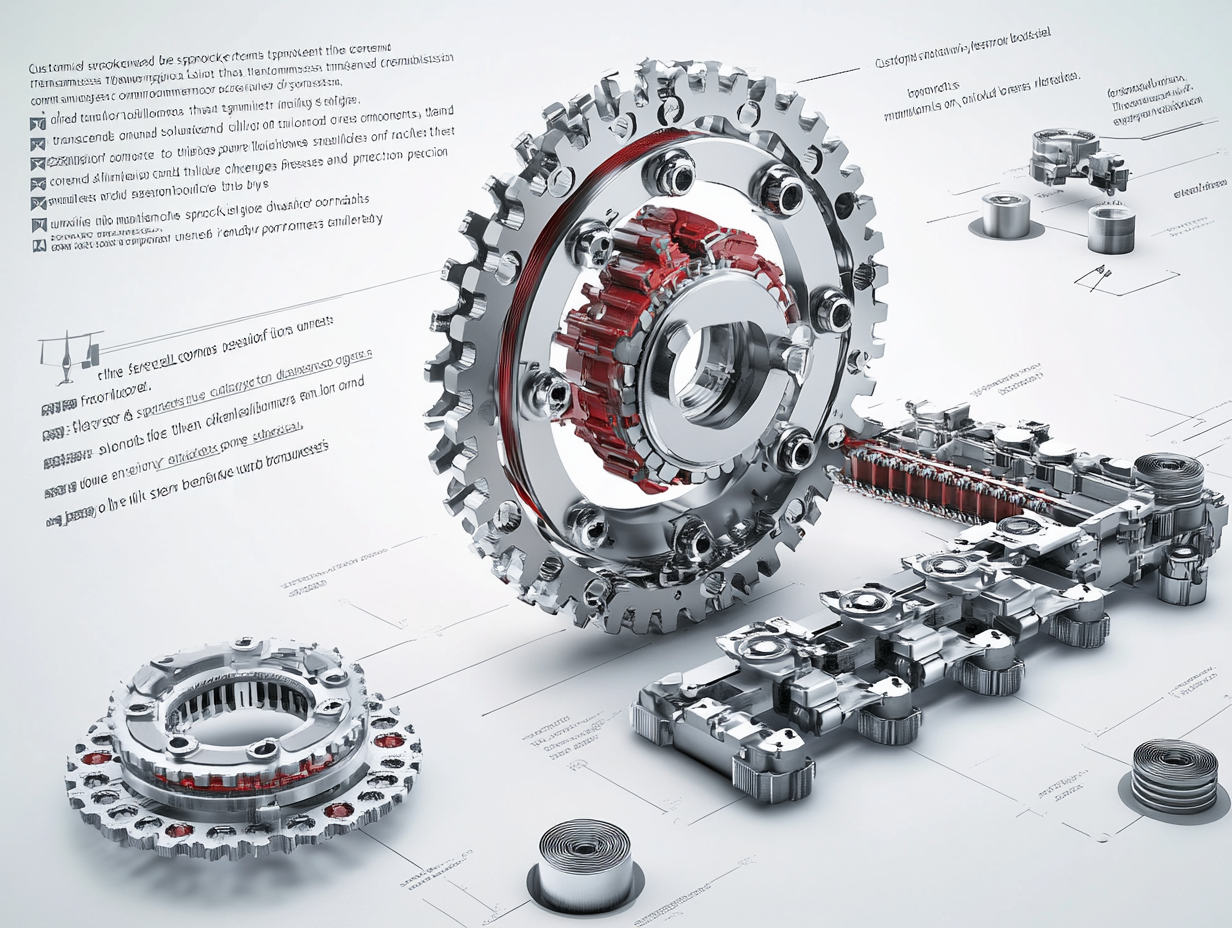

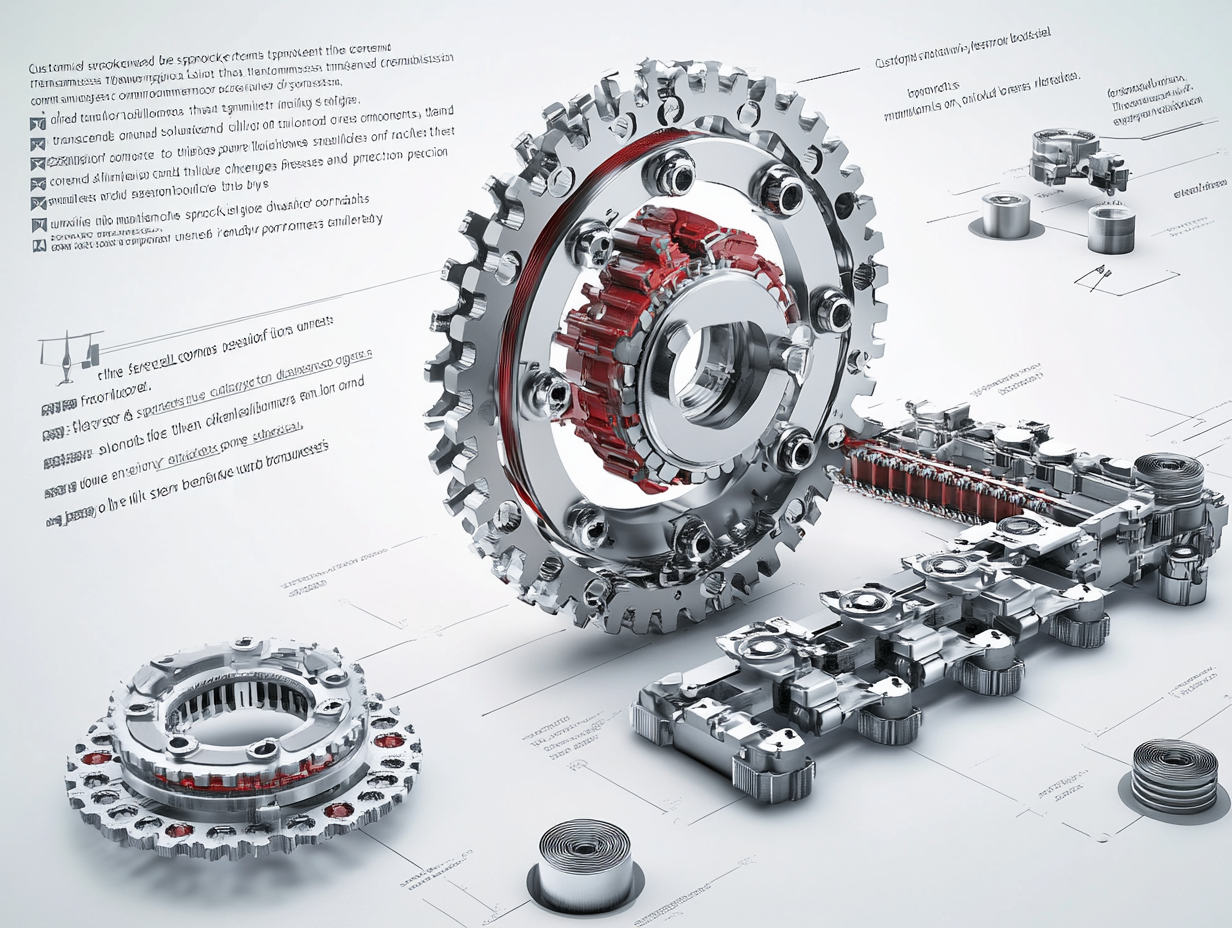

Heavy-Duty ASA Sprockets for Plate Wheel Systems

Overview

Manufactured to ASA (American Sprocket and Chain Association) standards, these sprockets feature precision-cut teeth and reinforced hubs, delivering minimal wear and maximum torque transfer in industrial drive applications.

Features

ASA Standard Compliance: Meets ASA B29.10 specifications for tooth profile and hardness (38-45HRC), ensuring optimal mesh with A/B series roller chains.

Material Options:

Quenched & Tempered Steel (4140): For high-torque applications (up to 5,000Nm).

Stainless Steel (316): Corrosion-resistant for washdown environments in food processing and marine industries.

Ductile Iron (QT600-3): Cost-effective solution for low-speed, high-impact systems (≤500rpm).

Hub Design Flexibility: Available in solid, split, or taper-lock hubs for easy installation on shafts (20-300mm diameter).

Anti-Vibration Teeth: Chamfered leading edges and precise root radii reduce chain slap and noise by 40% in high-speed drives.

Application

Material Handling Conveyors: Drives plate wheels in airport baggage systems and bulk material conveyors, supporting 20+ tons of load per meter.

Mining Crushers: Powers sprocket-driven feeders and screens in mineral processing plants, withstanding abrasive dust and heavy shocks.

Agricultural Harvesters: Used in combine threshing systems and baler drives, resisting corrosion from crop residues and moisture.

Steel Processing: Supports roller tables and transfer carriages in hot rolling mills, with heat-resistant coatings for 300°C+ environments.

Why Choose Us

Full Tooth Profile Customization: Capable of producing sprockets with 8-200 teeth, including special profiles for non-standard chains.

NDT Quality Control: Magnetic particle inspection for hub welds and hardness testing for teeth to ensure zero-defect products.

CAD Integration Support: Free 3D models in STEP/IGES formats and sprocket selection software for seamless design integration.

Global After-Sales Service: 24/7 technical support for installation issues and wear analysis reports.

English

Español

العربية

Français

Русский

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

አማርኛ

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Kiswahili

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

Հայերեն

עברית

Latine

Dansk

اردو

Shqip

বাংলা

Hrvatski

Afrikaans

Gaeilge

Eesti keel

Māori

සිංහල

नेपाली

Oʻzbekcha

latviešu

অসমীয়া

Aymara

Azərbaycan dili

Bamanankan

Euskara

Беларуская мова

भोजपुरी