High-Clearance Extended Pin Conveyor Chains for Bulk Handling

Overview

The High-Clearance Extended Pin Conveyor Chains are engineered for bulk material handling applications requiring easy attachment integration and high debris tolerance. Featuring extended pins and oversized link gaps, these chains allow seamless mounting of conveyor flights, buckets, or other attachments while resisting clogging from dust, granules, or irregular materials.

Features

Extended Pin Design: Pins protrude 5-15mm beyond side plates, providing secure attachment points without additional machining.

Debris-Resistant Geometry: Wide link spacing (20-30% larger than standard chains) and chamfered edges prevent material buildup, ideal for dirty environments.

High Load Capacity: Tensile strength up to 75kN with reinforced pins (55HRC), supporting heavy-duty conveyor loads up to 10 tons/m.

Temperature & Chemical Resistance: Available in heat-resistant alloy steel (up to 400°C) or corrosion-resistant duplex stainless steel for harsh processing lines.

ISO 1977 Compliance: Meets international standards for conveyor chain dimensions and mechanical properties.

Application

Grain & Food Processing: Powers bucket elevators, screw conveyors, and belt feeders in flour mills and rice processing plants.

Mining & Quarrying: Used in rock crusher feeders, vibrating screens, and ore conveyors with high dirt and moisture exposure.

Recycling Systems: Drives sorting conveyors and balers, resisting contamination from plastic fragments and metal shavings.

Construction Materials: Supports cement mixers, aggregate conveyors, and asphalt plants with durable resistance to abrasive particles.

Why Choose Us

Attachment Compatibility: Pre-engineered for quick installation of cleats, flights, and side panels, reducing conveyor setup time by 30%.

Custom Pin Lengths: Offer pin extensions from 3mm to 50mm for specialized attachment requirements.

Self-Cleaning Design: Regularly spaced links allow automatic debris shedding during operation, minimizing maintenance downtime.

Engineering Consultation: Free on-site assessment to optimize chain tension and attachment spacing for maximum conveyor efficiency.

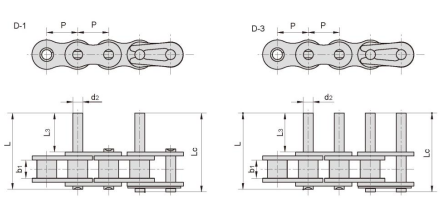

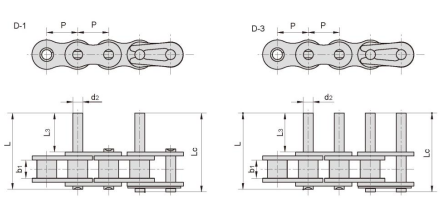

DIN/ISO

Chain

No. | ANSI

CHAIN NO. | P | b1 | d2 | L3 | L | Lc |

DIN/ISO

Cadena No | ANSI

Cadena No | mm | mm | mm | mm | mm | mm |

| 06C | 35 | 9.525 | 4.77 | 3.58 | 9.5 | 20.8 | 21.6 |

| 08A | 40 | 12.700 | 7.85 | 3.96 | 9.5 | 25.1 | 26.2 |

| 10A | 50 | 15.875 | 9.40 | 5.08 | 11.9 | 31.3 | 33.1 |

| 12A | 60 | 19.050 | 12.57 | 5.94 | 14.3 | 38.6 | 40.6 |

| 16A | 80 | 25.400 | 15.75 | 7.92 | 19.1 | 50.3 | 53.3 |

| 20A | 100 | 31.750 | 18.90 | 9.53 | 23.8 | 61.8 | 66.1 |

| 24A | 120 | 38.100 | 25.22 | 11.10 | 28.6 | 76.4 | 80.4 |

| 28A | 140 | 44.450 | 25.22 | 12.70 | 33.3 | 84.8 | 89.4 |

| 32A | 160 | 50.800 | 31.55 | 14.27 | 38.1 | 99.6 | 104.4 |

| 08B |

| 12.700 | 7.75 | 4.45 | 9.5 | 25.1 | 26.6 |

| 10B |

| 15.875 | 9.65 | 5.08 | 11.9 | 30.1 | 31.5 |

| 12B |

| 19.050 | 11.68 | 5.72 | 14.3 | 35.4 | 37.1 |

| 16B |

| 25.400 | 17.02 | 8.28 | 19.1 | 53.0 | 54.3 |

| 20B |

| 31.750 | 19.56 | 10.19 | 41.0 | 79.9 | 83.6 |

| 24B |

| 38.100 | 25.40 | 14.63 | 50.7 | 101.4 | 105.8 |

| 28B |

| 44.450 | 30.99 | 15.90 | 61.9 | 124.0 | 128.4 |

| 32B |

| 50.800 | 30.99 | 17.81 | 64.8 | 126.8 | 131.8 |

English

Español

العربية

Français

Русский

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

አማርኛ

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Kiswahili

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

Հայերեն

עברית

Latine

Dansk

اردو

Shqip

বাংলা

Hrvatski

Afrikaans

Gaeilge

Eesti keel

Māori

සිංහල

नेपाली

Oʻzbekcha

latviešu

অসমীয়া

Aymara

Azərbaycan dili

Bamanankan

Euskara

Беларуская мова

भोजपुरी