Sugar Chains

Product Description

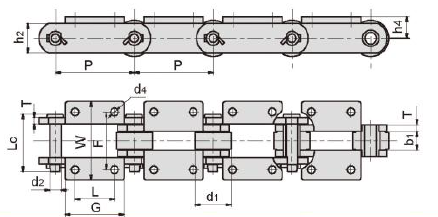

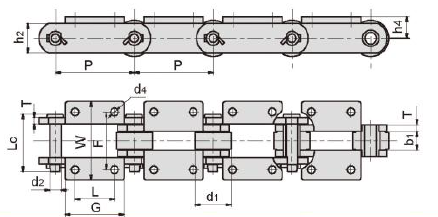

| CHAIN NO. | P | G | L | F | W | h4 | d4 |

| Cadena No | mm | mm | mm | mm | mm | mm | mm |

| HDC 9063 | 152.4 | 114.3 | 76.2 | 111.13 | 165.86 | 44.45 | 14.3 |

| HDC 2198 | 152.4 | 114.3 | 76.2 | 111.25 | 152.40 | 41.40 | 14.3 |

| CHAIN NO. | Pitch | Roller

diameter | Width

between

inner plates | Pin

diameter | Pin length | Plate depth | Plate

thickness | Ultimate

tensile

strength | Average

tensile

strength | Weight

por

meter |

| Cadena No | Paso | Diámetro

rodillo | Ancho

interior | Diámetro

pasador | Longitud

pasador | Altura

placas | Ancho

placas | Resis

rotura | Resis.

media

traccion | Peso

por

metro |

| P | d1

max | b1

min | d2

max | Lc

max | h2

max | T

max | Q

min | Q0 | q |

| mm | mm | mm | mm | mm | mm | mm | KN/LB | KN | kg/m |

| HDC 9063 | 152.4 | 76.20 | 38.1 | 23.83 | 103.2 | 61.00 | 10.3 | 445.0/100000 | 489.0 | 27.5 |

| HDC 2198 | 152.4 | 69.85 | 38.1 | 22.23 | 111.2 | 57.15 | 12.7 | 404.5/91000 | 445.0 | 27.9 |

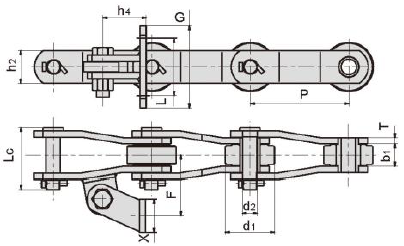

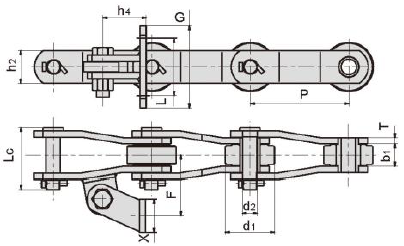

| CHAIN NO. | P | G | L | F | X | h4 |

| Cadena No | mm | mm | mm | mm | mm | mm |

| HDC 09060 | 152.4 | 114.3 | 82.6 | 88.9 | 50.8 | 111.25 |

| HDC 1796 | 152.4 | 114.3 | 82.6 | 88.9 | 50.8 | 111.25 |

| CHAIN NO. | Pitch | Roller

diameter | Width

between

inner plates | Pin

diameter | Pin length | Plate depth | Plate

thickness | Ultimate

tensile

strength | Average

tensile

strength |

| Cadena No | Paso | Diámetro

rodillo | Ancho

interior | Diametro

pasador | Longitud

pasador | Altura

placos | Ancho

placas | Resis.

rotura | Resis.

media

traccion |

| P | d1

max | b1

min | d2

max | Lc

max | h2

max | T

max | Q

min | Q0 |

| mm | mm | mm | mm | mm | mm | mm | KN/LB | KN |

| HDC 09060 | 152.4 | 69.85 | 38.1 | 19.05 | 96.6 | 50.80 | 9.65 | 270/60740 | 297.0 |

| HDC 1796 | 152.4 | 69.85 | 38.1 | 22.35 | 100.0 | 57.15 | 9.65 | 445/100100 | 489.5 |

High-Quality Sugar Chains for Industrial Applications

Product Introduction

High-quality sugar chains—specialized polymer-based chains engineered with sugar-derived monomers—are versatile, eco-friendly components designed to meet the rigorous demands of diverse industrial applications. Unlike traditional synthetic chains, these sugar chains leverage renewable biomass sources, offering a sustainable alternative without compromising on performance, durability, or functional flexibility.

Crafted through advanced polymerization processes, our sugar chains feature a uniform molecular structure with customizable chain lengths, cross-linking densities, and surface functional groups. This precision engineering ensures consistent mechanical properties, including tensile strength, elasticity, and chemical resistance, making them suitable for use in sectors such as food & beverage processing, pharmaceutical manufacturing, biotech equipment, packaging machinery, and agricultural automation.

Key Features

-

Renewable & Eco-Friendly Composition

Sourced from plant-based sugar monomers (e.g., glucose, sucrose, lactose), these chains reduce reliance on fossil fuels and boast excellent biodegradability in specific formulations, aligning with global sustainability goals and green manufacturing standards.

-

Tailored Functional Performance

We offer customizable modifications to suit application-specific needs:

Food-Grade Formulations: Non-toxic, odorless, and compliant with FDA, EU 10/2011, and other food safety regulations, ideal for conveyor systems in food processing lines.

Chemical Resistance: Modified sugar chains with enhanced resistance to acids, alkalis, and organic solvents, suitable for pharmaceutical and chemical handling equipment.

Low-Friction Surface: Coated variants minimize wear and noise when paired with sprockets or guide rails, reducing maintenance frequency in high-speed machinery.

-

Lightweight & High-Strength Ratio

Compared to metal chains, sugar chains are lightweight, which lowers the overall load of machinery and reduces energy consumption during operation. At the same time, their reinforced molecular structure enables them to withstand moderate to heavy loads, avoiding deformation or breakage under cyclic stress.

-

Easy Installation & Compatibility

Designed to match standard industrial chain dimensions (pitch, width), our sugar chains can directly replace traditional metal or plastic chains in existing equipment without additional modifications. They require minimal lubrication and are resistant to rust and corrosion, even in humid or harsh environments.

Typical Applications

Food Processing: Conveyor chains for bakery, beverage, and confectionery production lines, ensuring safe contact with food materials.

Pharmaceutical Industry: Transport chains for drug packaging and labeling equipment, meeting strict hygiene standards.

Biotech Equipment: Chains for laboratory sample handling systems, where chemical stability and non-contamination are critical.

Agricultural Machinery: Light-duty conveyor chains for sorting and packaging of fruits, vegetables, and grains.

Our high-quality sugar chains are manufactured under strict quality control systems, ensuring batch-to-batch consistency and compliance with international industrial standards. We also provide customized design services to address unique application challenges, helping clients optimize machinery performance while reducing environmental impact.

Choose our sugar chains for your industrial projects—where sustainability, quality, and functionality come together.

English

Español

العربية

Français

Русский

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

አማርኛ

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Kiswahili

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

Հայերեն

עברית

Latine

Dansk

اردو

Shqip

বাংলা

Hrvatski

Afrikaans

Gaeilge

Eesti keel

Māori

සිංහල

नेपाली

Oʻzbekcha

latviešu

অসমীয়া

Aymara

Azərbaycan dili

Bamanankan

Euskara

Беларуская мова

भोजपुरी