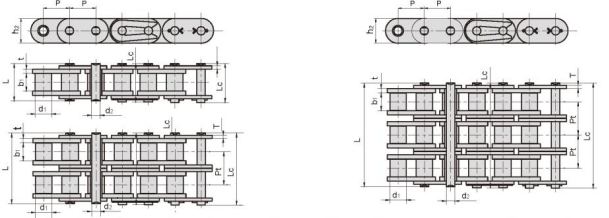

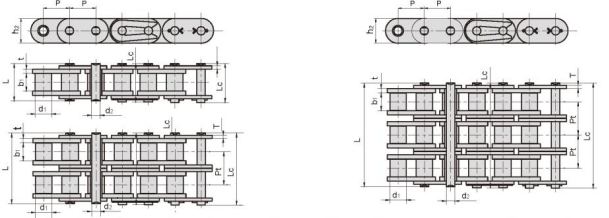

High-Stiffness Straight Side Plate Roller Chains for Industrial Drives (A SERIES)

Overview

The High-Stiffness Straight Side Plate Roller Chains (A Series) are engineered for heavy-duty industrial applications requiring maximum structural rigidity and consistent load distribution. Featuring precision-machined straight side plates and heat-treated components, these chains eliminate lateral deflection under high tension, delivering reliable power transmission in demanding drive systems. The robust design balances high tensile strength with smooth articulation, making them ideal for machinery subject to shock loads or misalignment.

Features

Straight Side Plate Design: Thicker, flat-profile plates (15-25% stiffer than curved designs) reduce plate bending, ensuring uniform load distribution across all links.

Enhanced Tensile Strength: Heat-treated alloy steel pins (62HRC) and bushings provide tensile ratings from 12kN to 100kN, with a 1.8x safety factor for sudden load spikes.

Low Friction Operation: Polished rollers (Ra≤0.8μm) and precision-matched bushing bores minimize energy loss, improving drive system efficiency by 12%.

Corrosion Protection: Optional duplex coatings (zinc-nickel base + PTFE topcoat) offer 1,000+ hours of salt spray resistance (ASTM B117), suitable for outdoor or marine environments.

ANSI/ISO Compliance: Meets ANSI B29.1 (A Series) and ISO 606 standards, ensuring compatibility with global sprocket systems.

Application

Heavy Machinery: Powers cement mill drives, steel rolling mills, and paper machine presses requiring stable torque transfer.

Mining Conveyors: Used in long-distance belt conveyors and bucket elevators in underground mines, resisting dust and abrasive particles.

Construction Equipment: Drives crawler tracks on excavators and bulldozers, withstanding repeated impact from uneven terrain.

Industrial Gearboxes: Integrates with reducers and gear drives in packaging machinery and material handling systems.

Why Choose Us

Custom Plate Thickness: Offer 3mm to 15mm side plate options for tailored stiffness in unique load scenarios.

3D Alignment Analysis: Free CAD-based drive system simulation to optimize chain tension and sprocket alignment.

Quick-Change Links: Patented master links reduce downtime by 50% during maintenance or replacement.

Global Inventory Network: 20+ distribution centers ensuring 48-hour delivery for standard A Series chains.

DINASO

Chain

No. | ANSI

CHAIN

NO. | Pitch | Roller

diameter | Width

between

plates | Pin

diameter | Pin

length | Inner

plate

depth | Plate

thickness | Transverse

pitch | Ultimate

tensile

strength | Average

tensile

strength | Weight

per meter |

DIN/ISO

Cadena

No | ANSI

Cadena

No | Paso | Diámetro

rodillo | Ancho

interior | Diámetro

pasador | Longitud

pasador | Altura

placas | Ancho

placas | Paso

transversal | Resis.

rotura | Resis.

media

tracción | Peso

por

metro |

| P | d1

max | b1

min | d2

max | L

max | Lc

max | h2

max | T

max | Pt | Q

min | Q | q |

| mm | mm | mm | mm | mm | mm | mm | mm | mm | kN/LB | KN | kg/m |

| *C35-1 | 9.525 | 5.08 | 4.77 | 3.58 | 13.3 | 14.3 | 9.00 | 1.30 | - | 7.9/1795 | 10.8 | 0.41 |

| C08A-1 | C40-1 | 12.700 | 7.95 | 7.85 | 3.96 | 16.6 | 18.8 | 12.00 | 1.50 | - | 14.1/3273 | 17.5 | 0.73 |

| C10A-1 | C50-1 | 15.875 | 10.16 | 9.40 | 5.08 | 20.7 | 23.3 | 15.09 | 2.03 | - | 22.2/5045 | 29.4 | 1.23 |

| C12A-1 | C60-1 | 19.050 | 11.91 | 12.57 | 5.94 | 25.9 | 28.3 | 18.0/18.2 | 2.42 | - | 31.8/7227 | 41.5 | 1.81/1.83 |

| C16A-1 | C80-1 | 25.400 | 15.88 | 15.75 | 7.92 | 32.7 | 36.5 | 24.00 | 3.25 | - | 56.7/12886 | 69.4 | 3.09 |

| C20A-1 | C100-1 | 31.750 | 19.05 | 18.90 | 9.53 | 40.4 | 44.7 | 30.00 | 4.00 | - | 88.5/20114 | 109.2 | 4.56 |

| C24A-1 | C120-1 | 38.100 | 22.23 | 25.22 | 11.10 | 50.3 | 54.3 | 35.70 | 4.80 | - | 127.0/28864 | 156.3 | 6.86 |

| C28A-1 | C140-1 | 44.450 | 25.40 | 25.22 | 12.70 | 54.4 | 59.0 | 41.00 | 5.60 | - | 172.4/39182 | 212.0 | 8.49 |

| C32A-1 | C160-1 | 50.800 | 28.58 | 31.55 | 14.27 | 64.8 | 69.6 | 47.80 | 6.40 | - | 226.8/51545 | 278.9 | 11.50 |

| C08A-2 | C40-2 | 12.700 | 7.95 | 7.85 | 3.96 | 31.0 | 33.2 | 12.00 | 1.50 | 14.38 | 28.2/6409 | 35.9 | 1.43 |

| C10A-2 | C50-2 | 15.875 | 10.16 | 9.40 | 5.08 | 38.9 | 41.4 | 15.09 | 2.03 | 18.11 | 44.4/10091 | 58.1 | 2.42 |

| C12A-2 | C60-2 | 19.050 | 11.91 | 12.57 | 5.94 | 48.8 | 51.1 | 18.0/18.2 | 2.42 | 22.78 | 63.6/14455 | 82.1 | 3.58/3.62 |

| C16A-2 | C80-2 | 25.400 | 15.88 | 15.75 | 7.92 | 62.7 | 65.8 | 24.00 | 3.25 | 29.29 | 113.4/25773 | 141.8 | 6.12 |

| C20A-2 | C100-2 | 31.750 | 19.05 | 18.90 | 9.53 | 76.4 | 80.5 | 30.00 | 4.00 | 35.76 | 177.0/40227 | 219.4 | 9.08 |

| C24A-2 | C120-2 | 38.110 | 22.23 | 25.22 | 11.10 | 95.8 | 99.7 | 35.70 | 4.80 | 45.44 | 254.0/57727 | 314.9 | 13.60 |

| C28A-2 | C140-2 | 44.450 | 25.40 | 25.22 | 12.70 | 103.3 | 107.9 | 41.00 | 5.60 | 48.87 | 344.8/78364 | 427.5 | 16.86 |

| C32A-2 | C160-2 | 50.800 | 28.58 | 31.55 | 14.27 | 123.3 | 128.1 | 47.80 | 6.40 | 58.55 | 453.6/103091 | 562.4 | 22.90 |

| C08A-3 | C40-3 | 12.700 | 7.95 | 7.85 | 3.96 | 45.4 | 47.6 | 12.00 | 1.50 | 14.38 | 42.3/9614 | 50.0 | 2.14 |

| C10A-3 | C50-3 | 15.875 | 10.16 | 9.40 | 5.08 | 57.0 | 59.5 | 15.09 | 2.03 | 18.11 | 66.6/15136 | 77.8 | 3.62 |

| C12A-3 | C60-3 | 19.050 | 11.91 | 12.57 | 5.94 | 71.5 | 73.9 | 18.0/18.2 | 2.42 | 22.78 | 95.4/21682 | 111.1 | 5.36/5.41 |

| C16A-3 | C80-3 | 25.400 | 15.88 | 15.75 | 7.92 | 91.7 | 95.1 | 24.00 | 3.25 | 29.29 | 170.1/38659 | 198.4 | 9.10 |

| C20A-3 | C100-3 | 31.750 | 19.05 | 18.90 | 9.53 | 112.2 | 116.3 | 30.00 | 4.00 | 35.76 | 265.5/60341 | 309.6 | 13.60 |

| C24A-3 | C120-3 | 38.100 | 22.23 | 25.22 | 11.10 | 141.4 | 145.2 | 35.70 | 4.80 | 45.44 | 381.0/86591 | 437.2 | 20.43 |

| C28A-3 | C140-3 | 44.450 | 25.40 | 25.22 | 12.70 | 152.2 | 156.8 | 41.00 | 5.60 | 48.87 | 517.2/117545 | 593.3 | 25.23 |

| C32A-3 | C160-3 | 50.800 | 28.58 | 31.55 | 14.27 | 181.8 | 186.6 | 47.80 | 6.40 | 58.55 | 680.4/154636 | 780.6 | 34.19 |

English

Español

العربية

Français

Русский

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

አማርኛ

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Kiswahili

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

Հայերեն

עברית

Latine

Dansk

اردو

Shqip

বাংলা

Hrvatski

Afrikaans

Gaeilge

Eesti keel

Māori

සිංහල

नेपाली

Oʻzbekcha

latviešu

অসমীয়া

Aymara

Azərbaycan dili

Bamanankan

Euskara

Беларуская мова

भोजपुरी