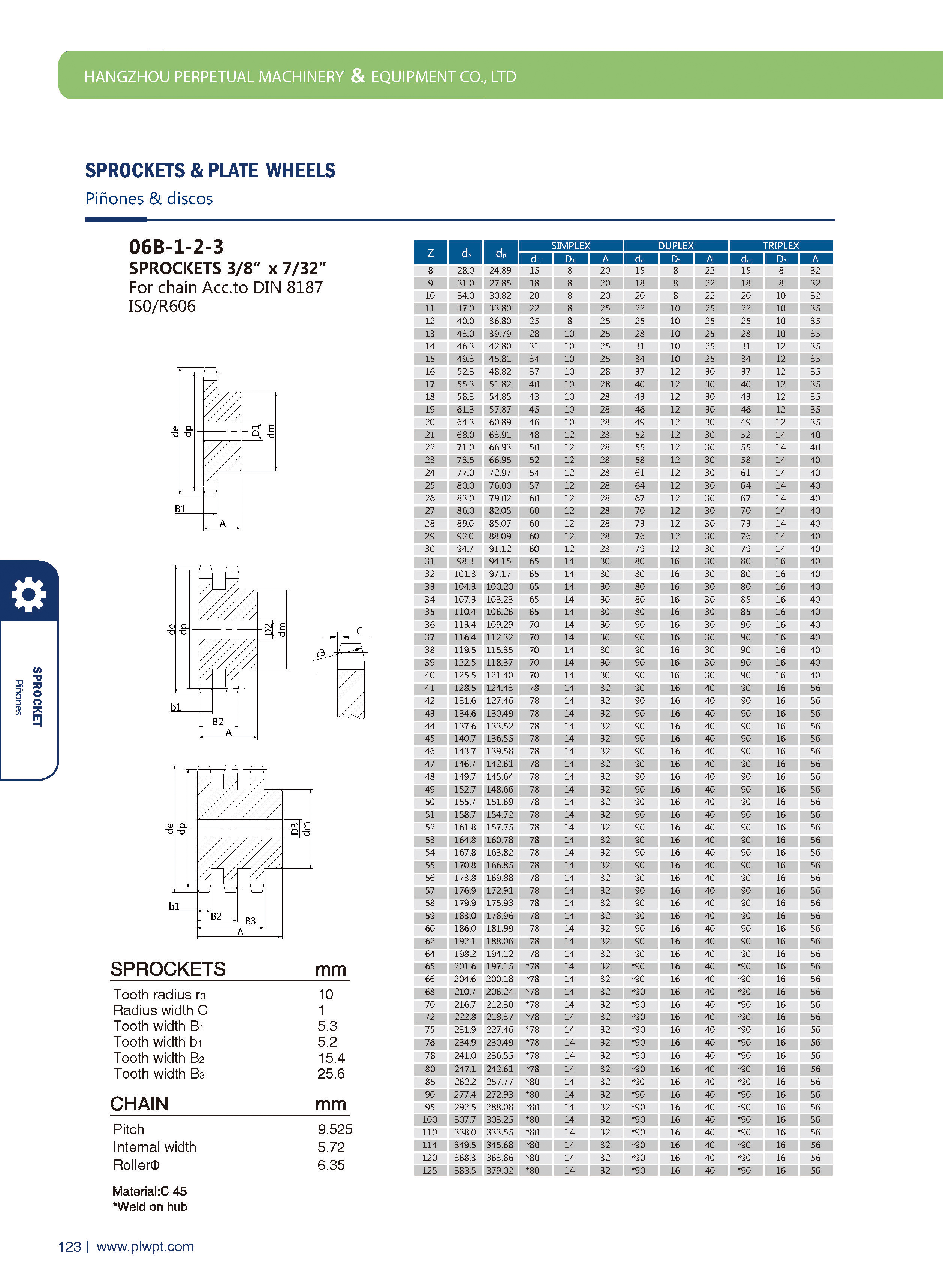

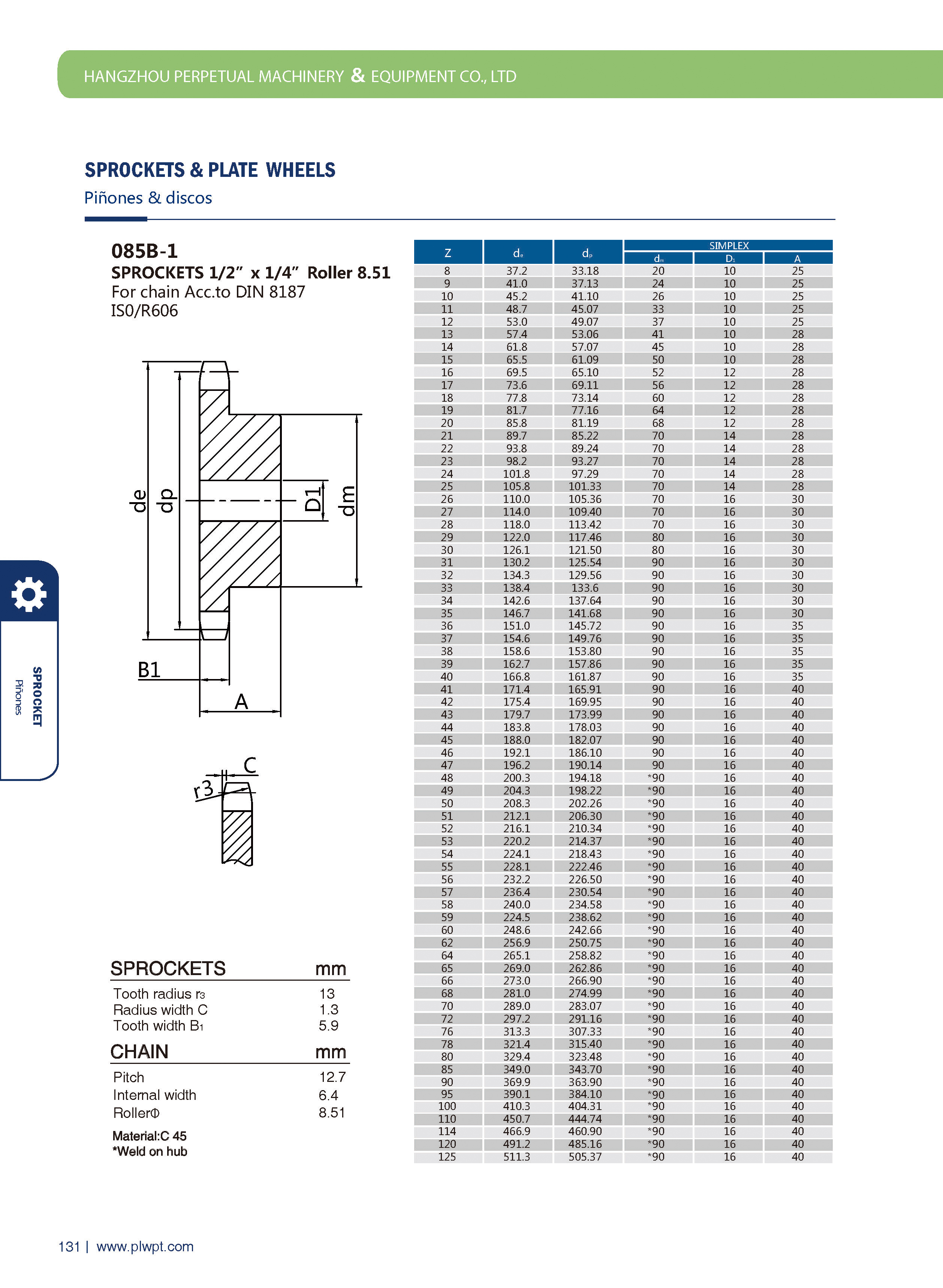

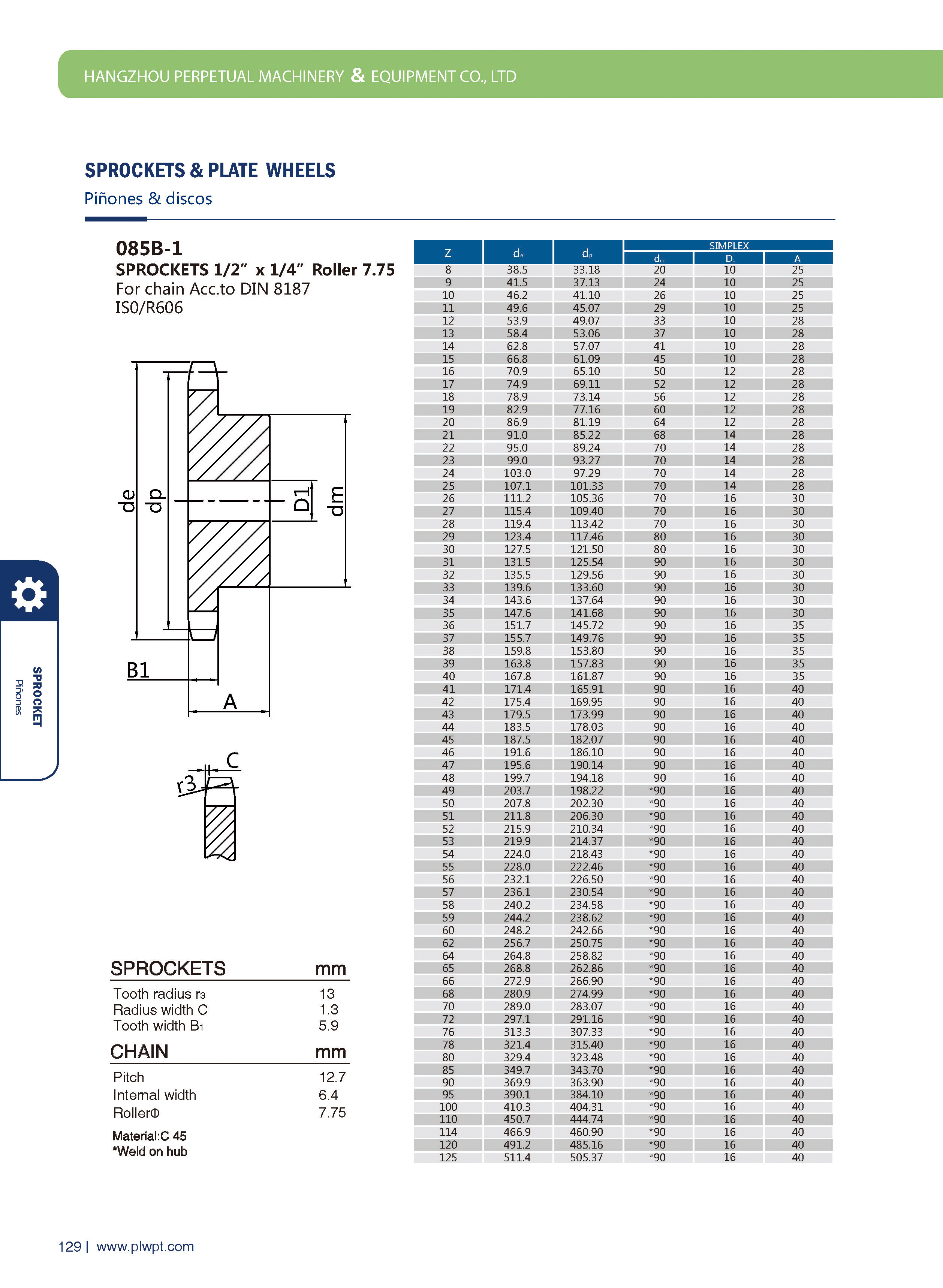

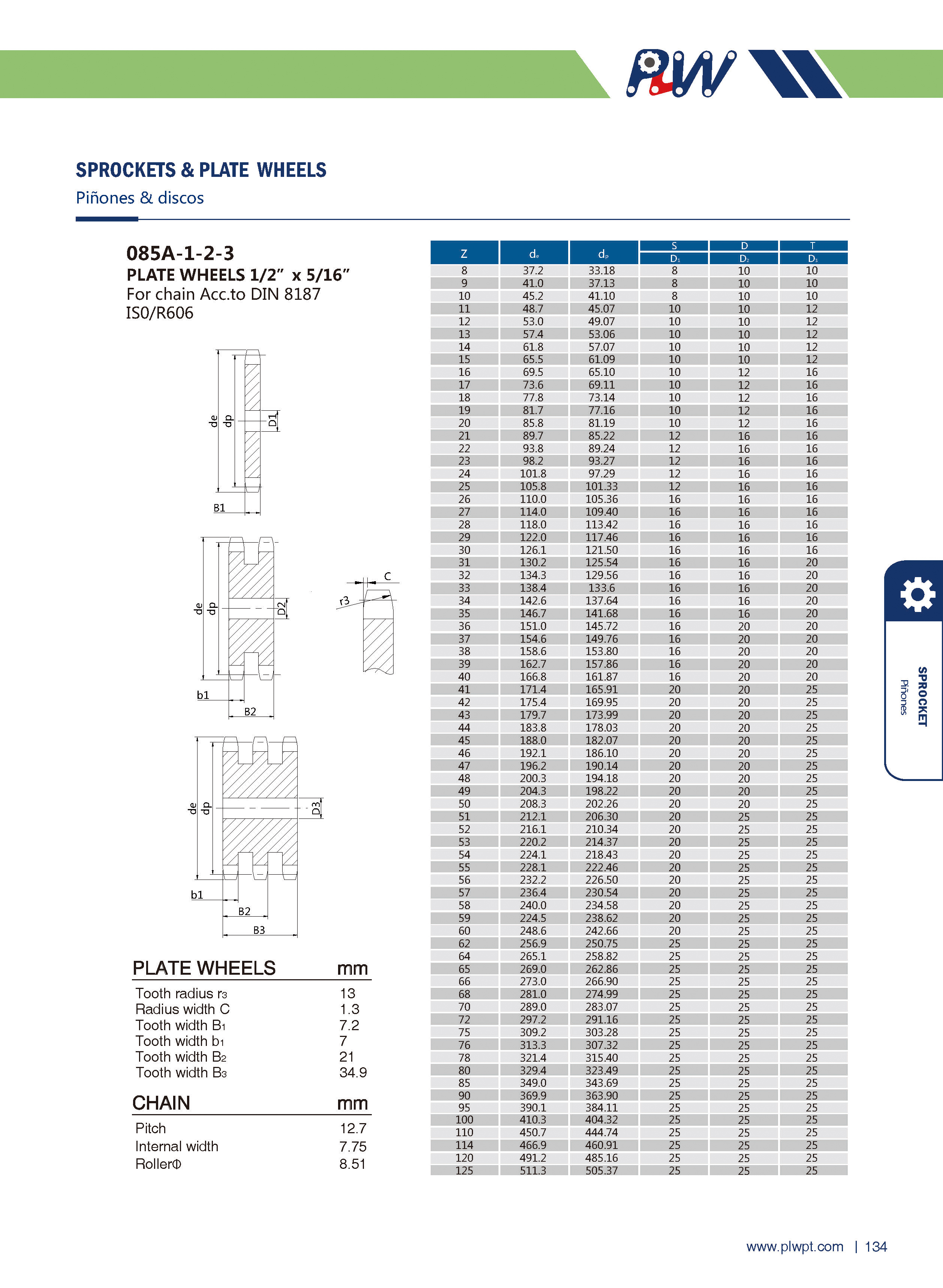

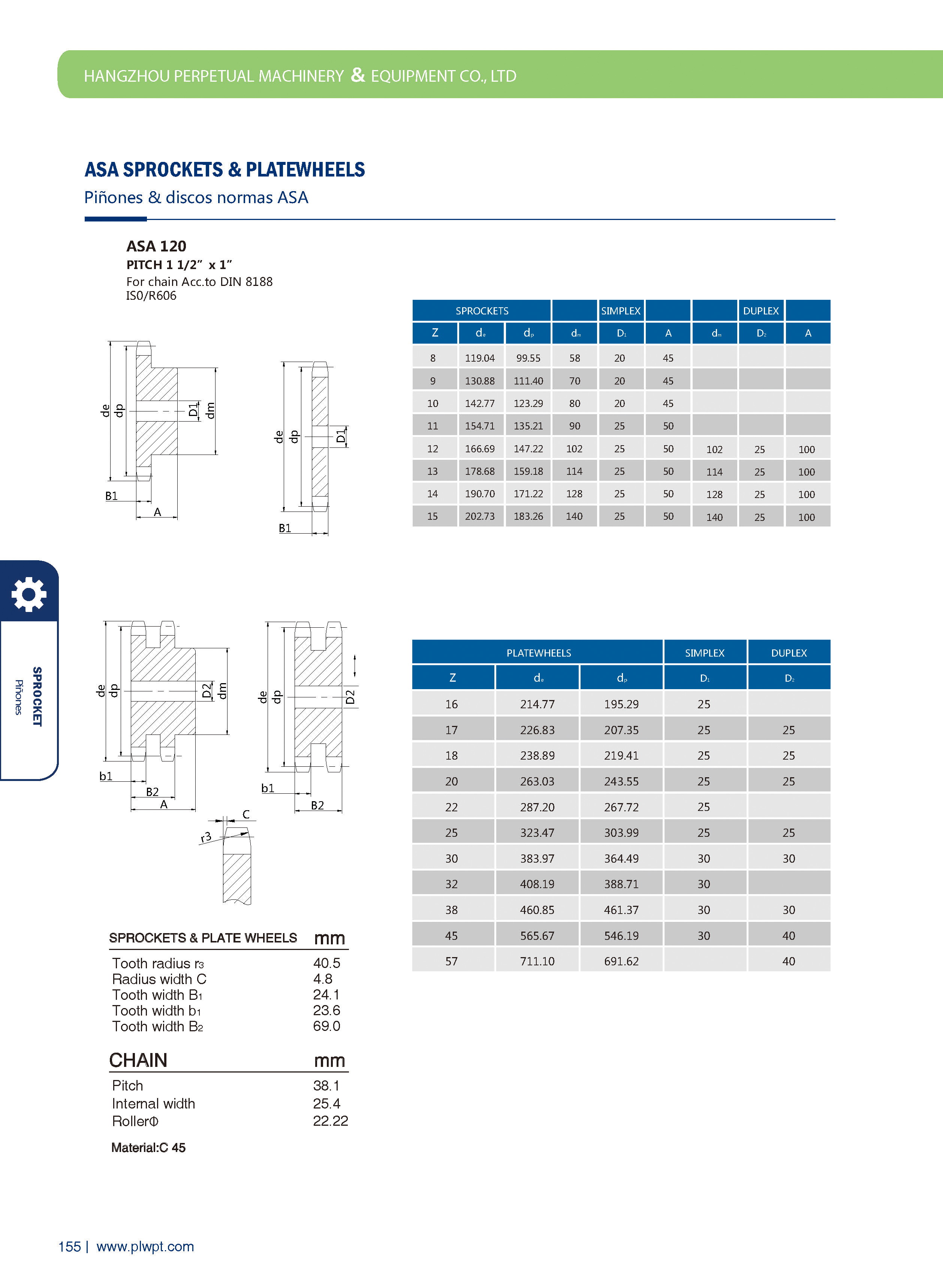

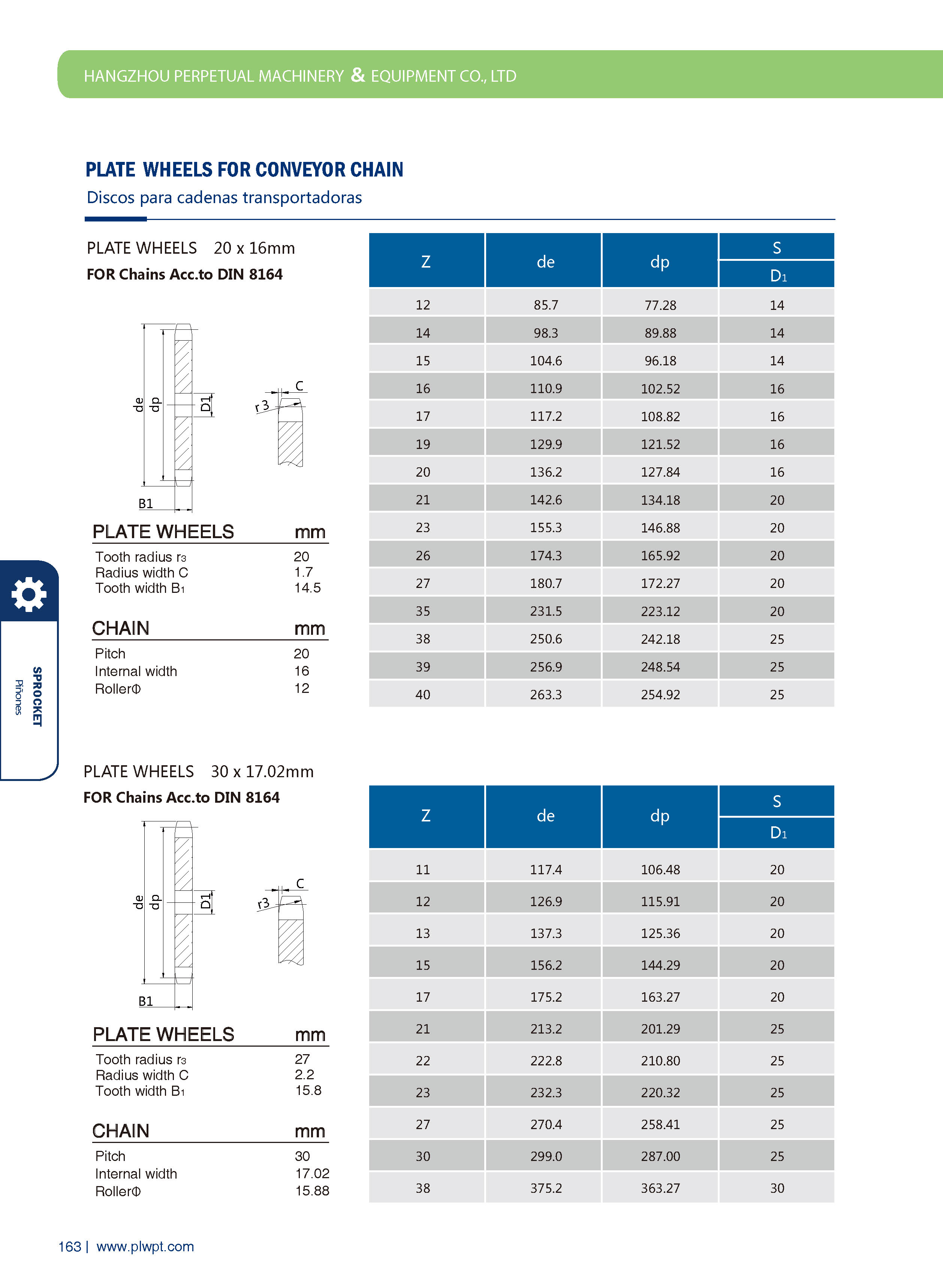

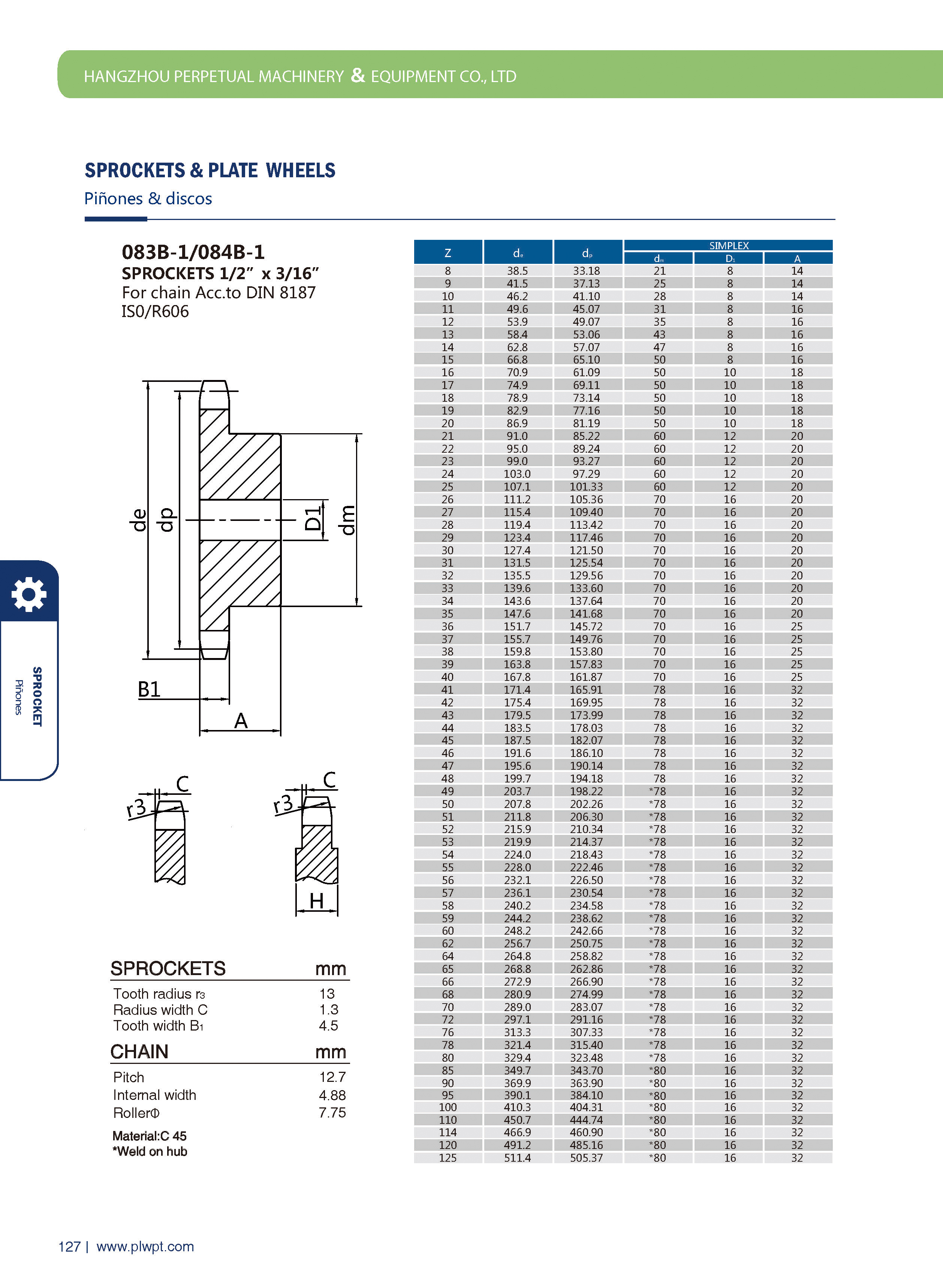

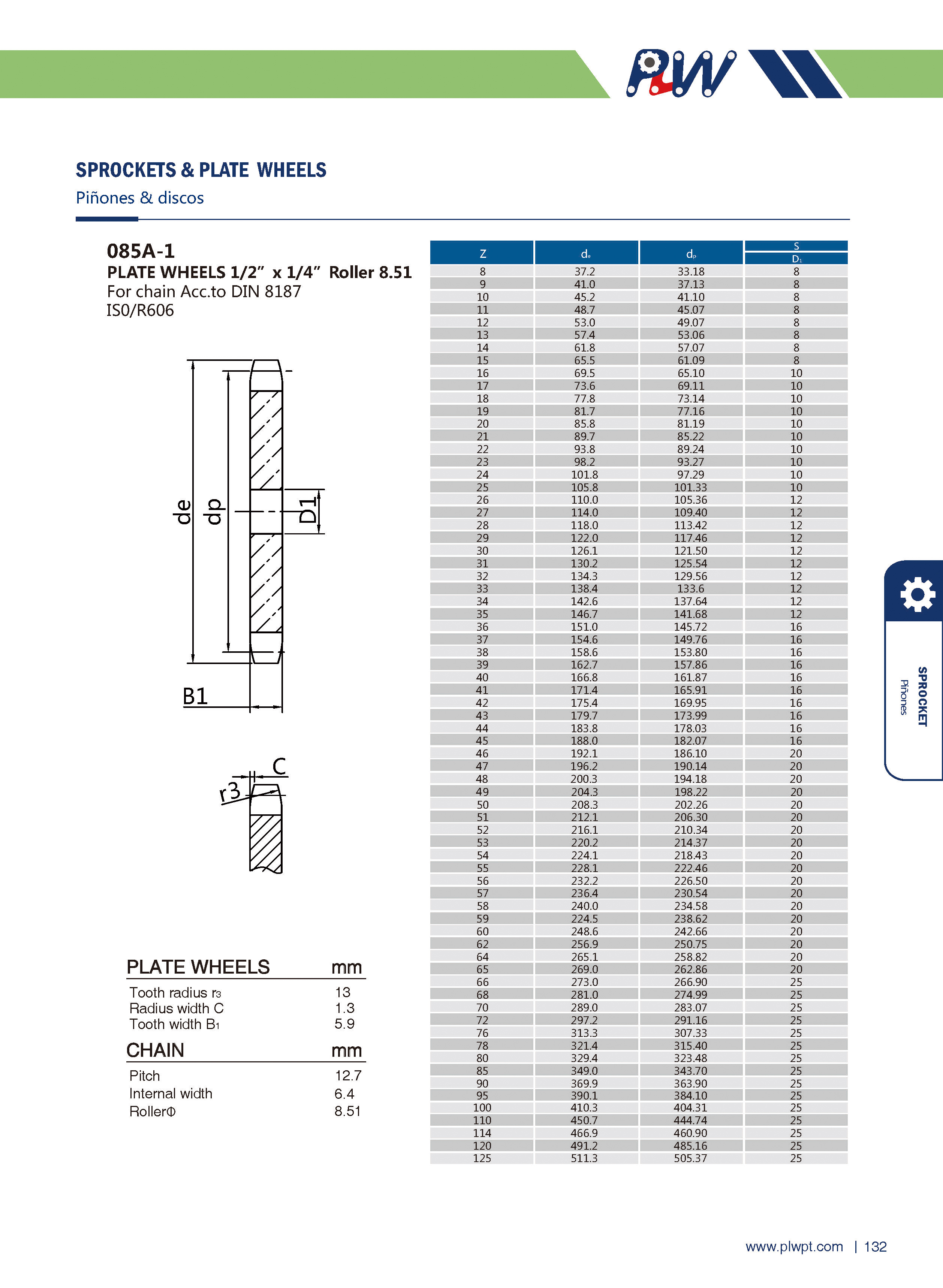

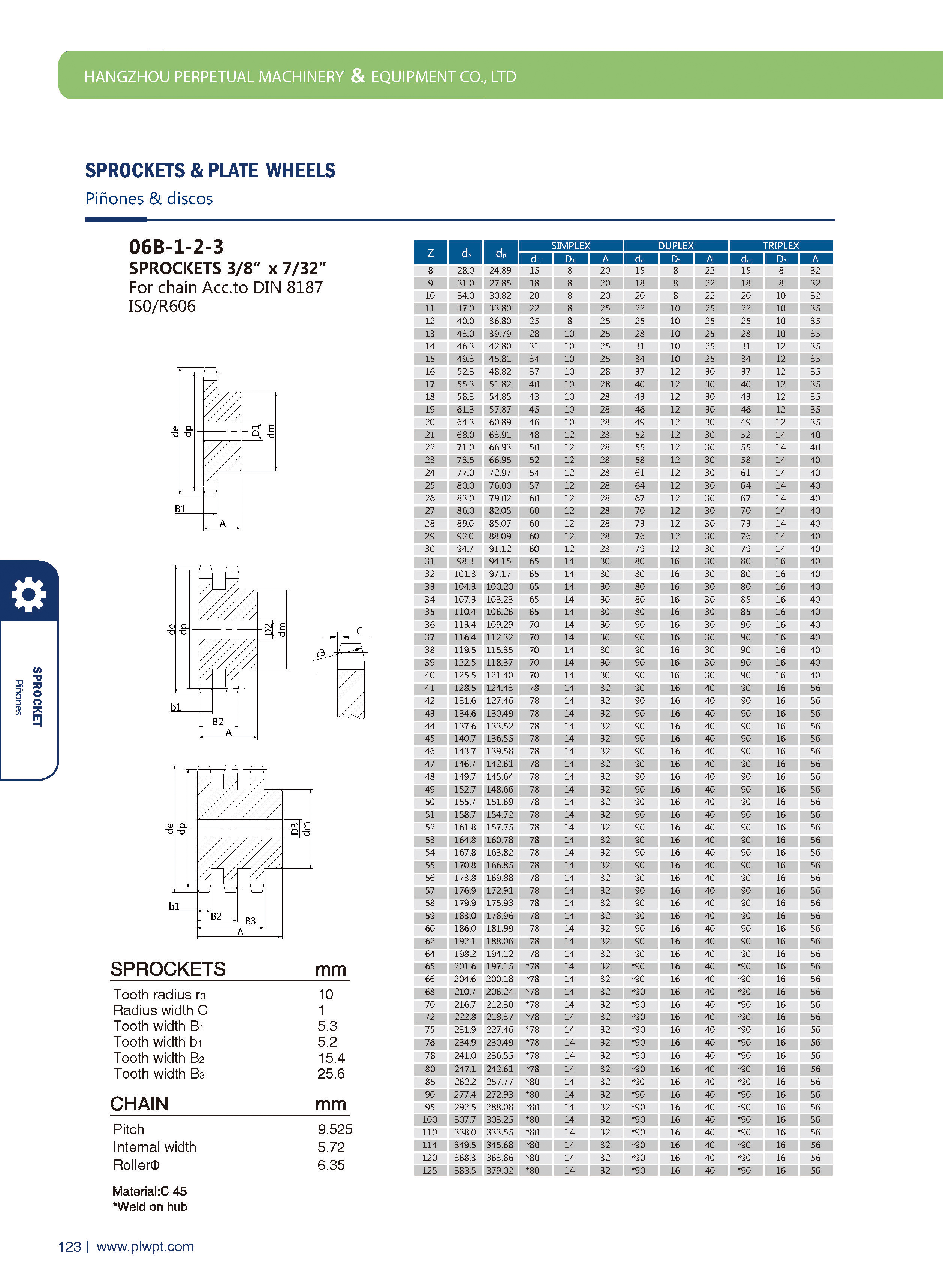

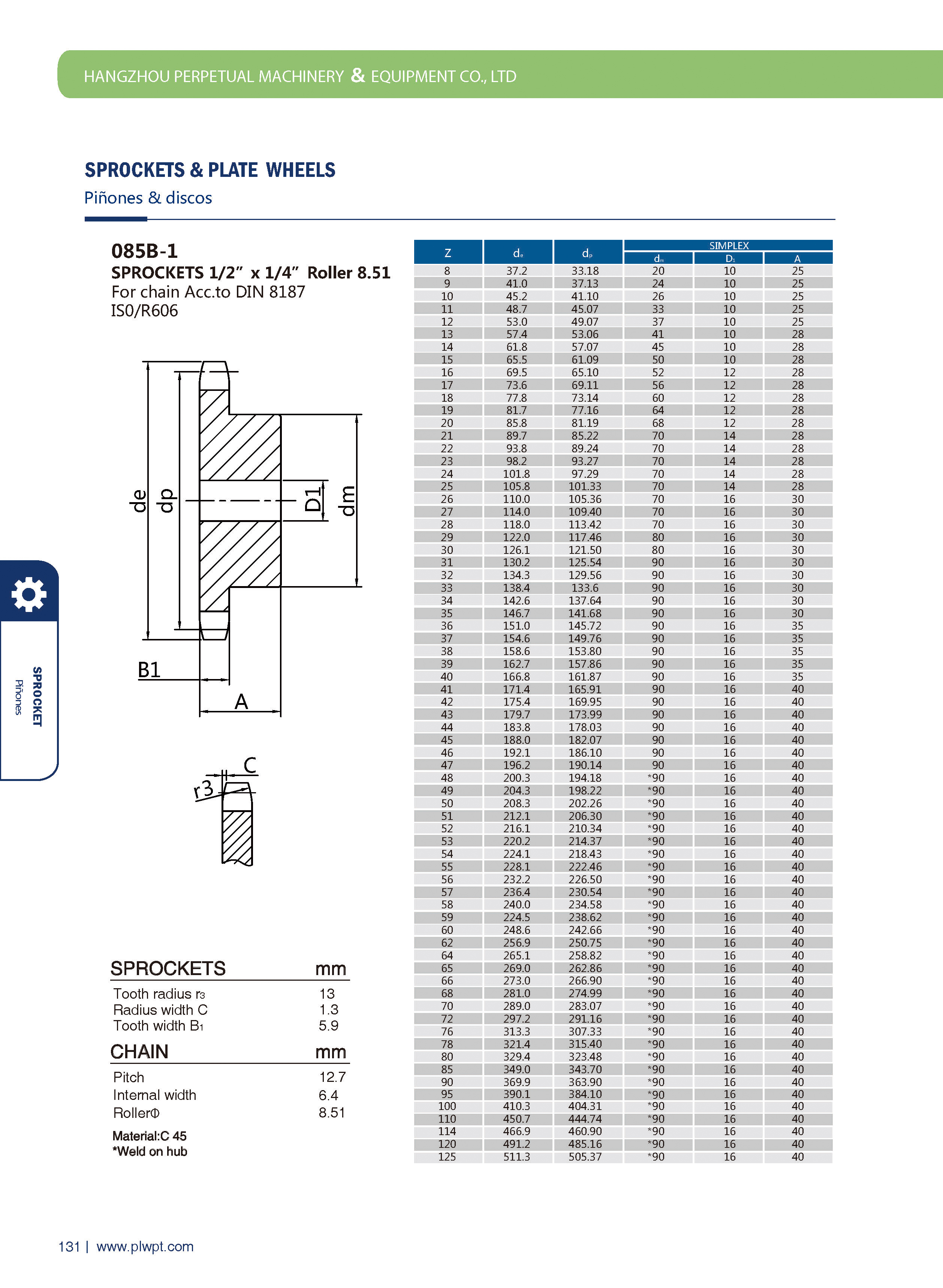

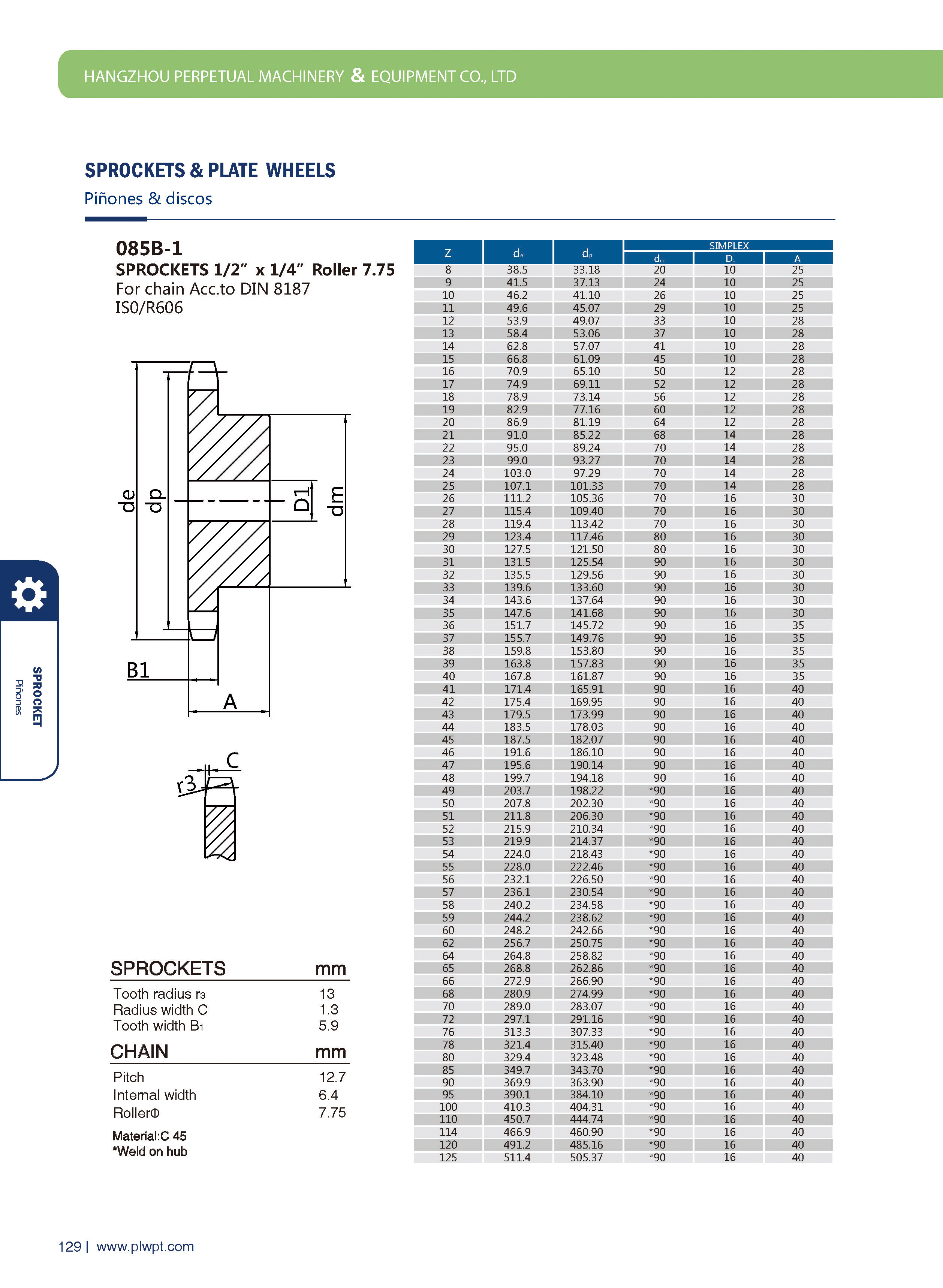

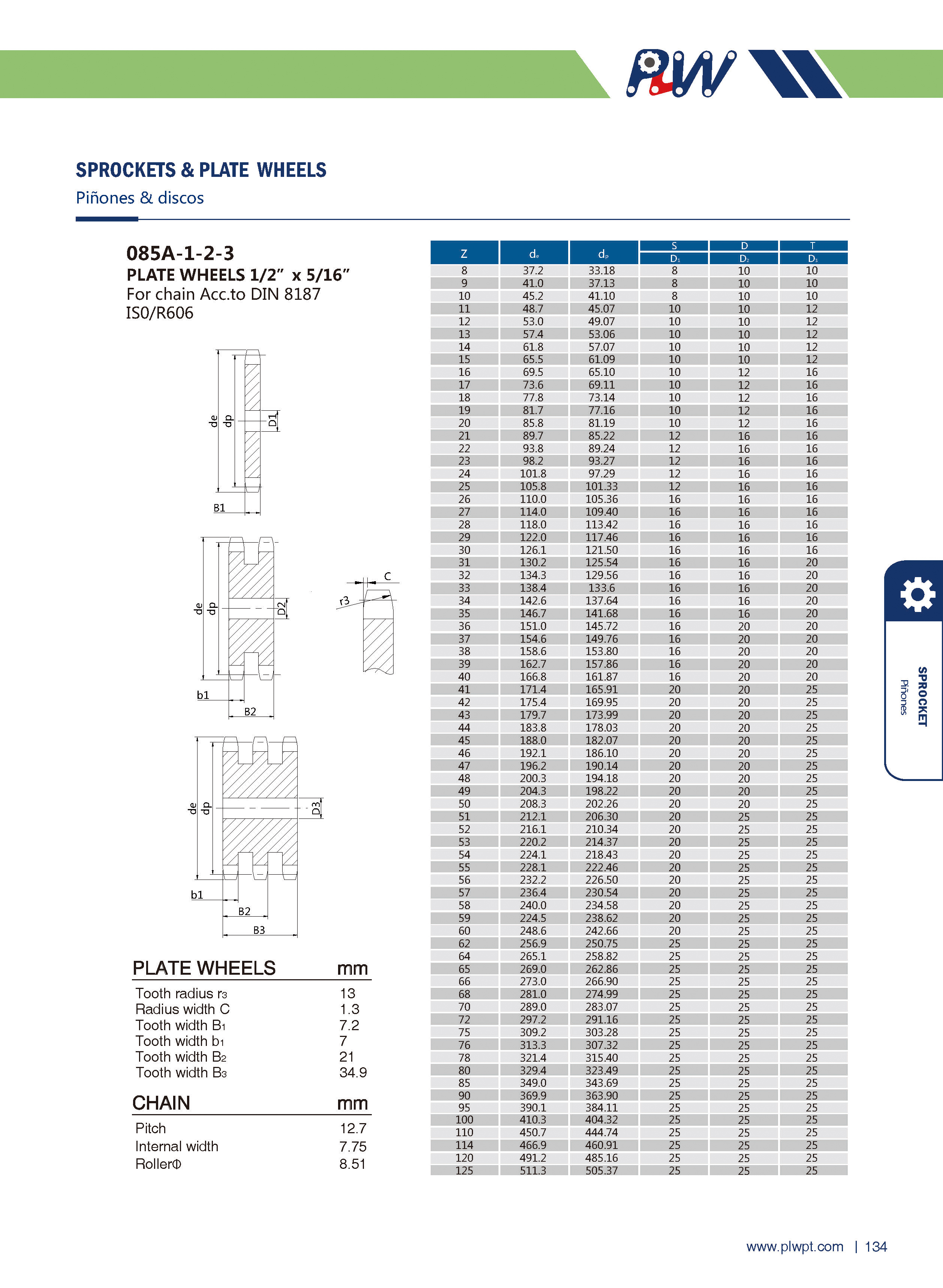

Industrial Standard Custom Carbon Steel Stainless Steel Simplex Duplex Plate Wheels Drive Conveyor Roller Chain Sprocket for Power Transmission

A sprocket is a key component widely used in mechanical transmission systems, characterized by evenly and regularly distributed teeth along its edge.

Its main function is to transmit power and motion through precise meshing with a chain. During operation, the rotation of the sprocket drives the meshing chain to move, thereby transferring power from one component to another. For example, in the transmission systems of bicycles and motorcycles, sprockets work with chains to transmit the power from pedaling to the wheels; in industrial equipment such as conveyors and cranes, the combination of sprockets and chains is also relied on to realize material transportation or heavy object lifting.

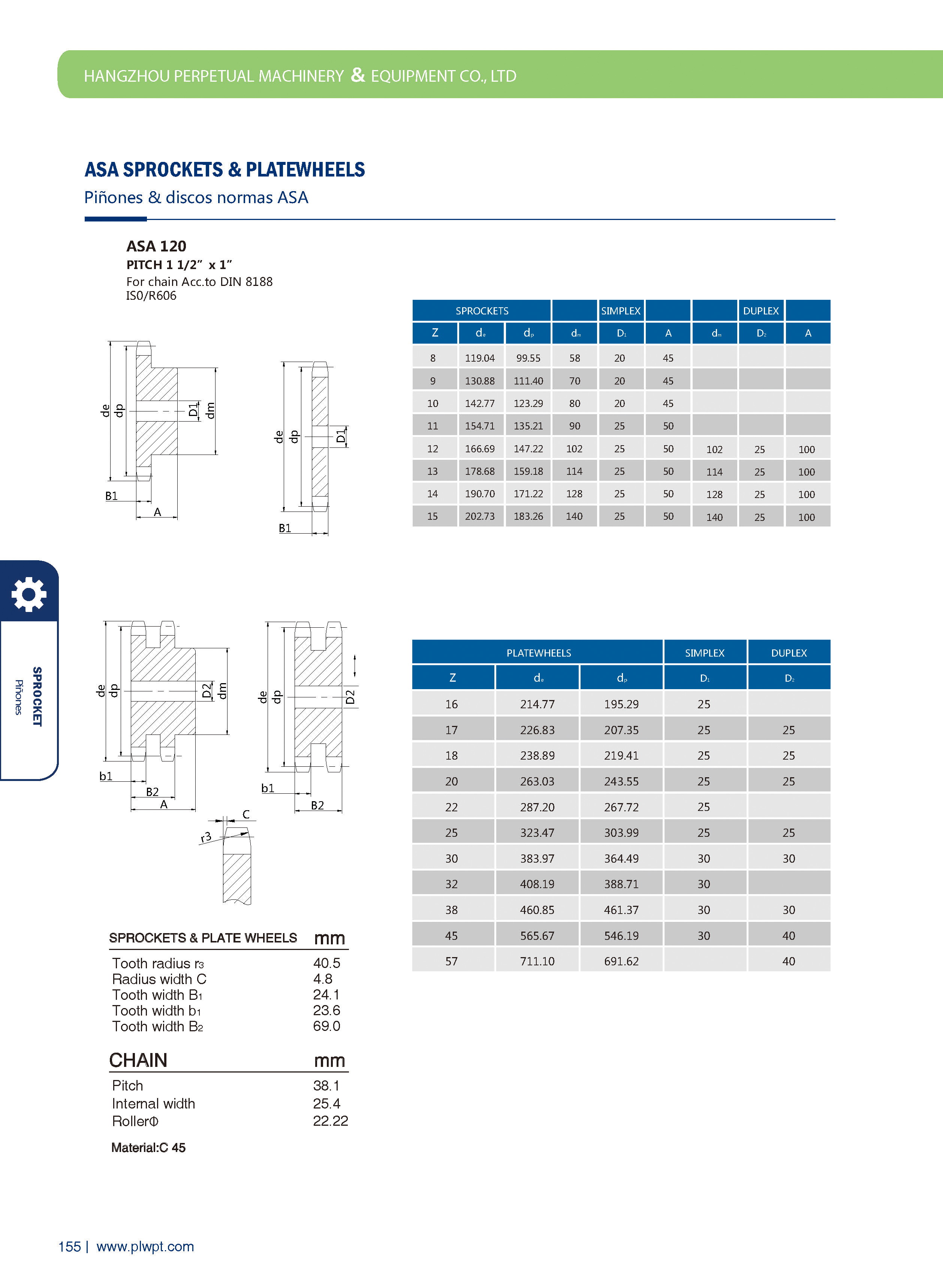

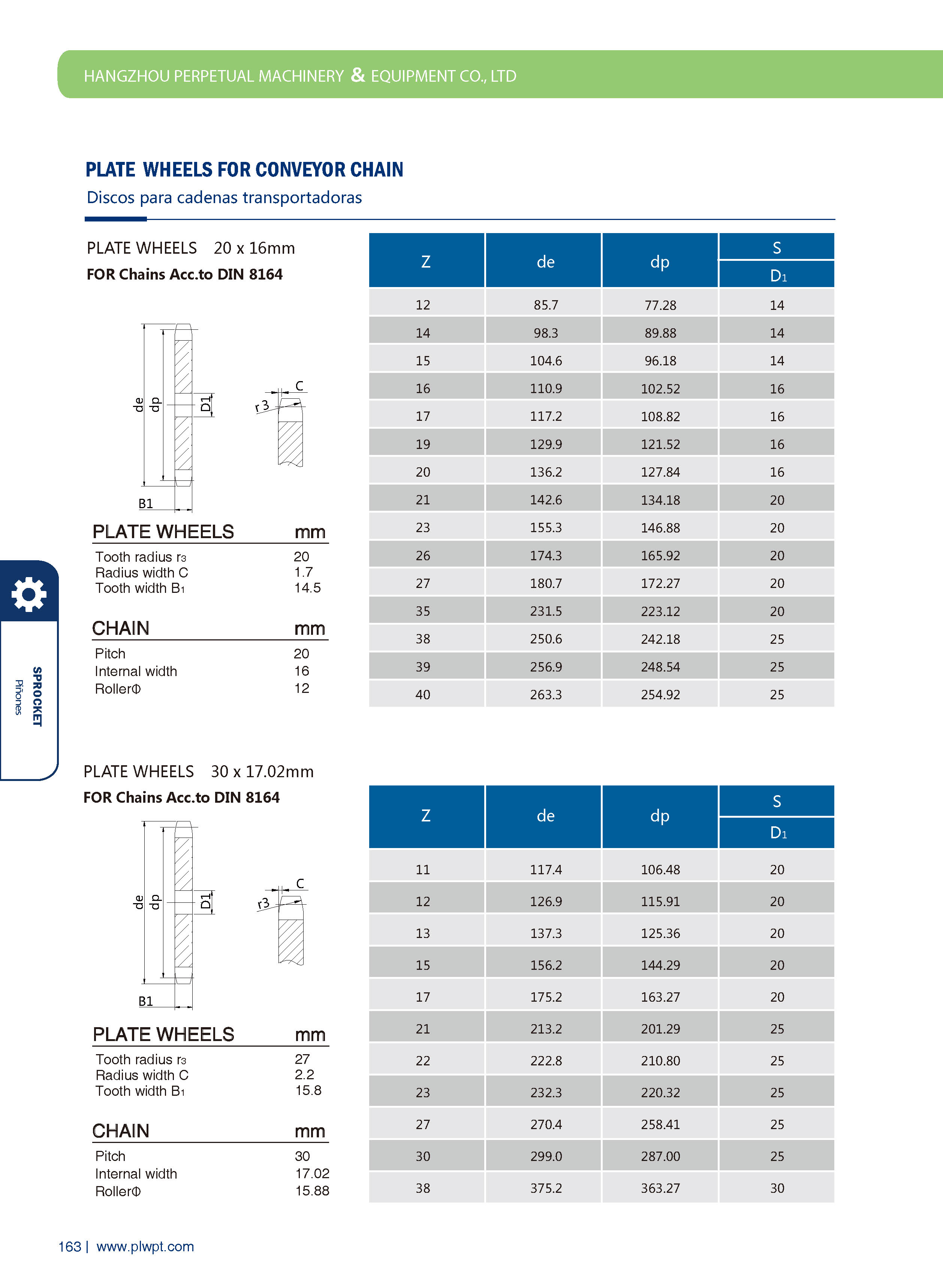

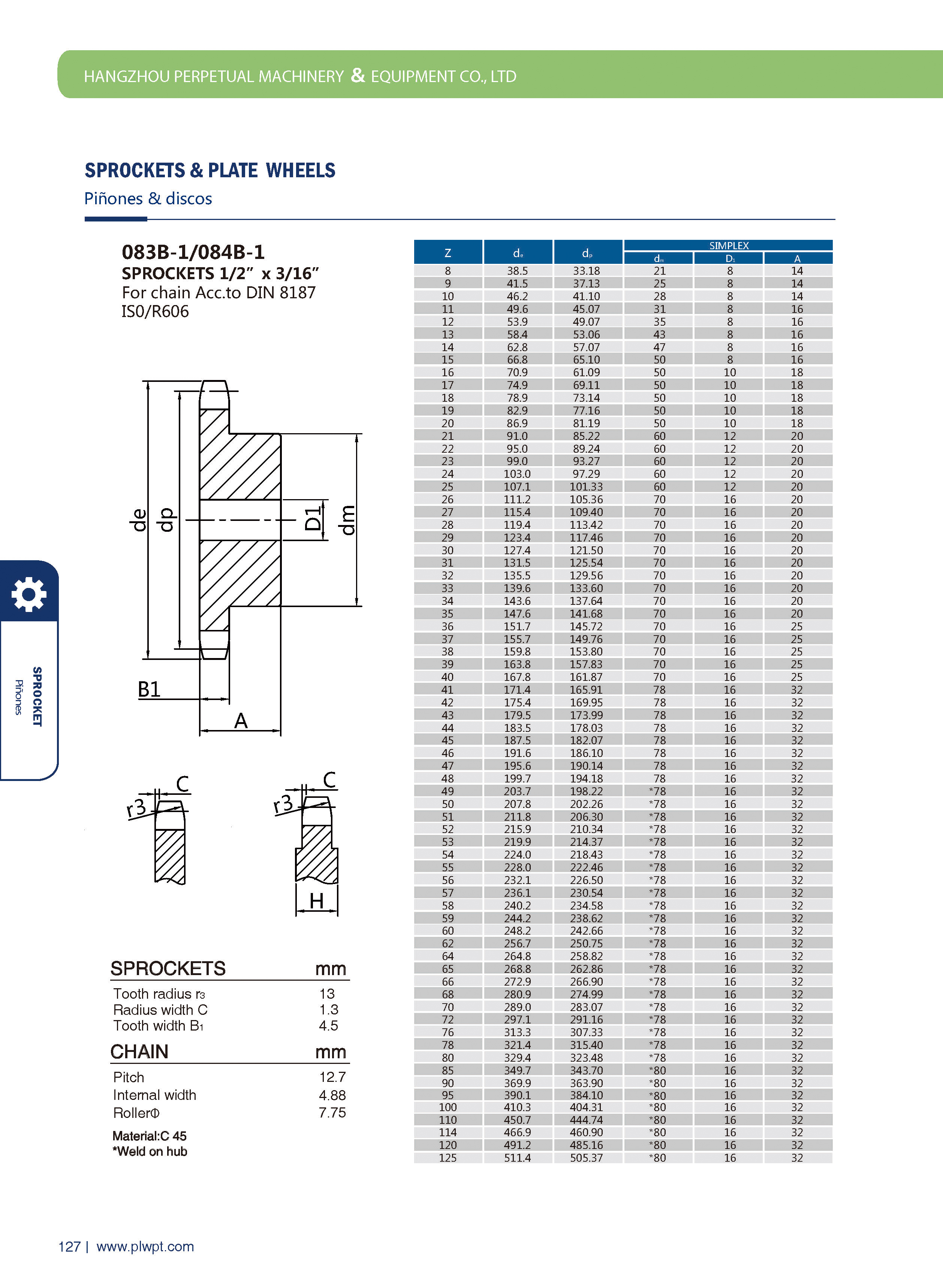

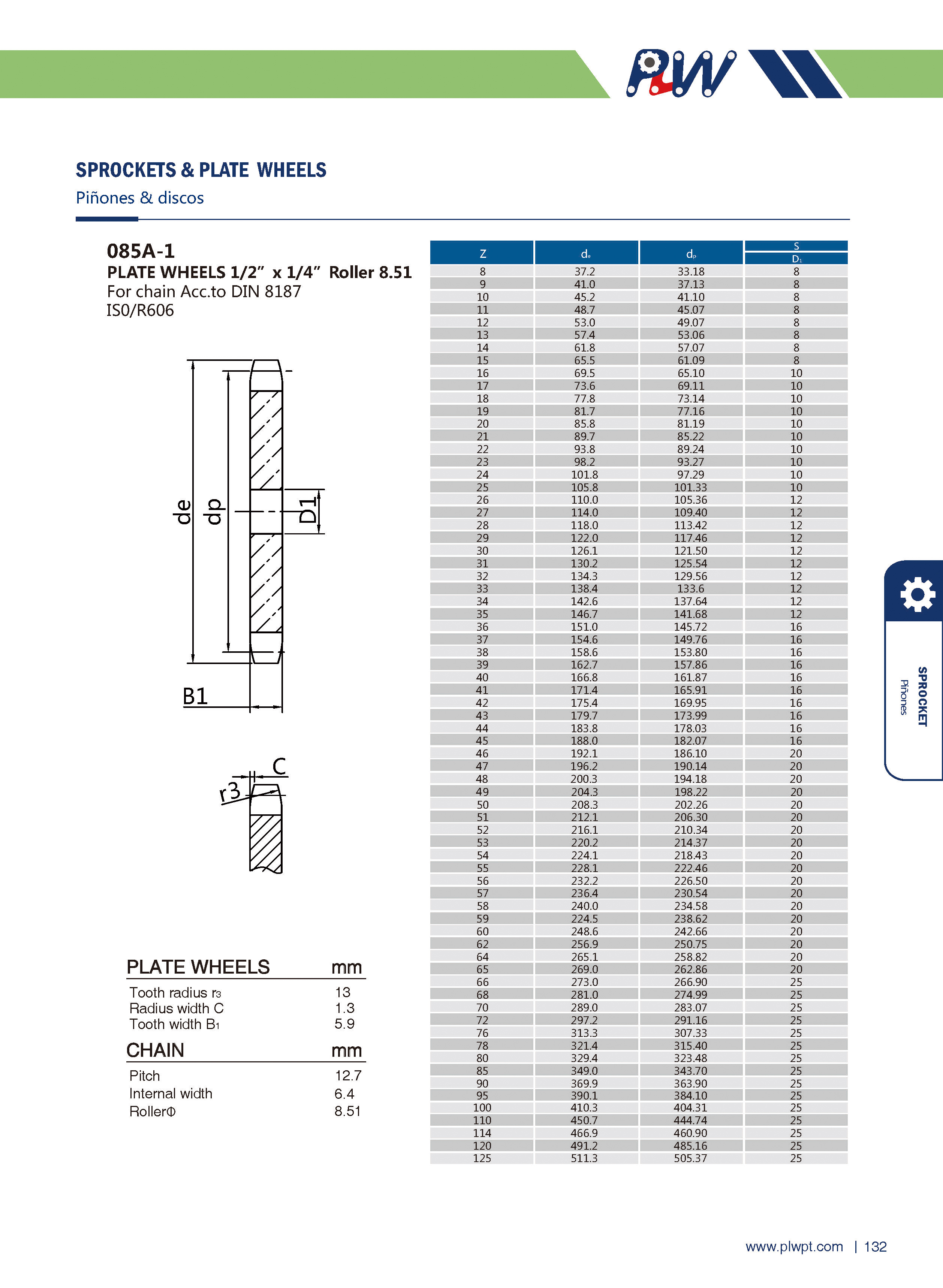

The design of sprockets usually needs to consider compatibility with chains, including parameters such as tooth shape, number of teeth, and pitch, to ensure smooth and efficient transmission. Meanwhile, depending on different working environments and load requirements, sprockets are made of different materials (such as steel, cast iron, etc.) and may undergo surface treatments (such as quenching, chrome plating) to improve wear resistance and service life.

Sprockets, with their ability to work with chains for efficient and stable power transmission, find extensive applications in numerous fields. Here are specific scenarios:

-

Transportation sector: In the transmission systems of bicycles and motorcycles, sprockets cooperate with chains to transfer pedal power or engine power to the wheels; some automobiles (such as auxiliary transmission devices of certain heavy-duty trucks) and tractors also use sprockets for power distribution.

-

Industrial production field: Various conveyors (like assembly line conveyer belts and mine conveyors) drive the conveying belts or scrapers to move through sprockets and chains, enabling continuous material transportation; equipment such as cranes and elevators utilize the combination of sprockets and chains to lift heavy objects; in the transmission systems of machine tools, sprockets can be used to transmit motion and power, ensuring the coordinated operation of various components.

-

Agricultural machinery sector: Agricultural equipment such as harvesters, seeders, and threshers rely on the transmission of sprockets and chains to drive the operation of working parts like cutting, conveying, and seeding mechanisms.

-

Logistics and warehousing field: Equipment like stackers and sorters in automated three-dimensional warehouses realize the handling and sorting of goods through sprocket-chain transmission.

-

Other fields: In some fitness equipment (such as spinning bikes), sprockets are used to simulate power transmission during cycling; the transmission systems of some ships and engineering machinery (such as certain auxiliary transmission parts of excavators) also apply sprockets.

English

Español

العربية

Français

Русский

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

አማርኛ

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Kiswahili

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

Հայերեն

עברית

Latine

Dansk

اردو

Shqip

বাংলা

Hrvatski

Afrikaans

Gaeilge

Eesti keel

Māori

සිංහල

नेपाली

Oʻzbekcha

latviešu

অসমীয়া

Aymara

Azərbaycan dili

Bamanankan

Euskara

Беларуская мова

भोजपुरी