PLW Standard Sprockets Precision-Engineered Sprockets for Roller Chains, Meets International Standards

Overview

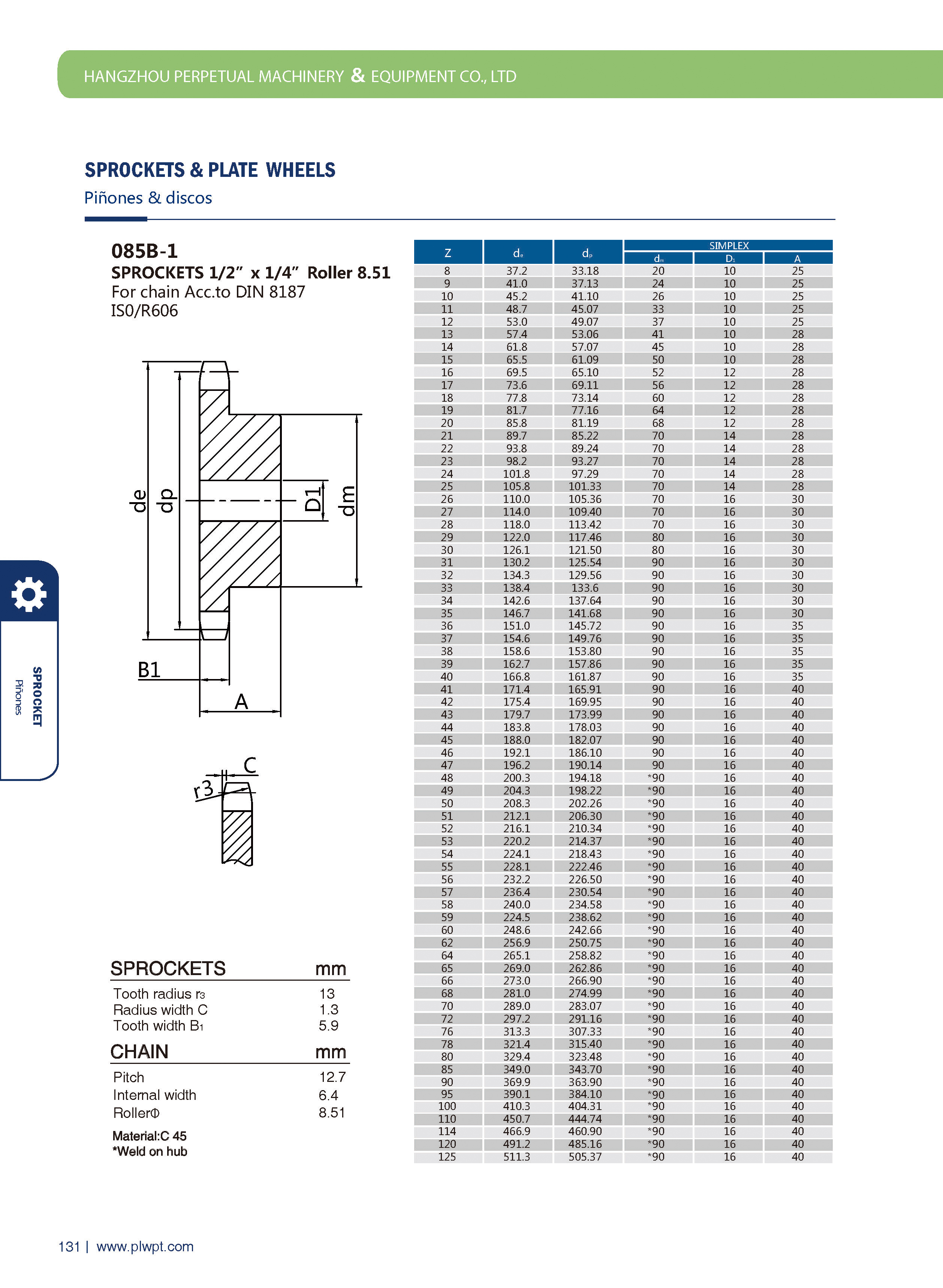

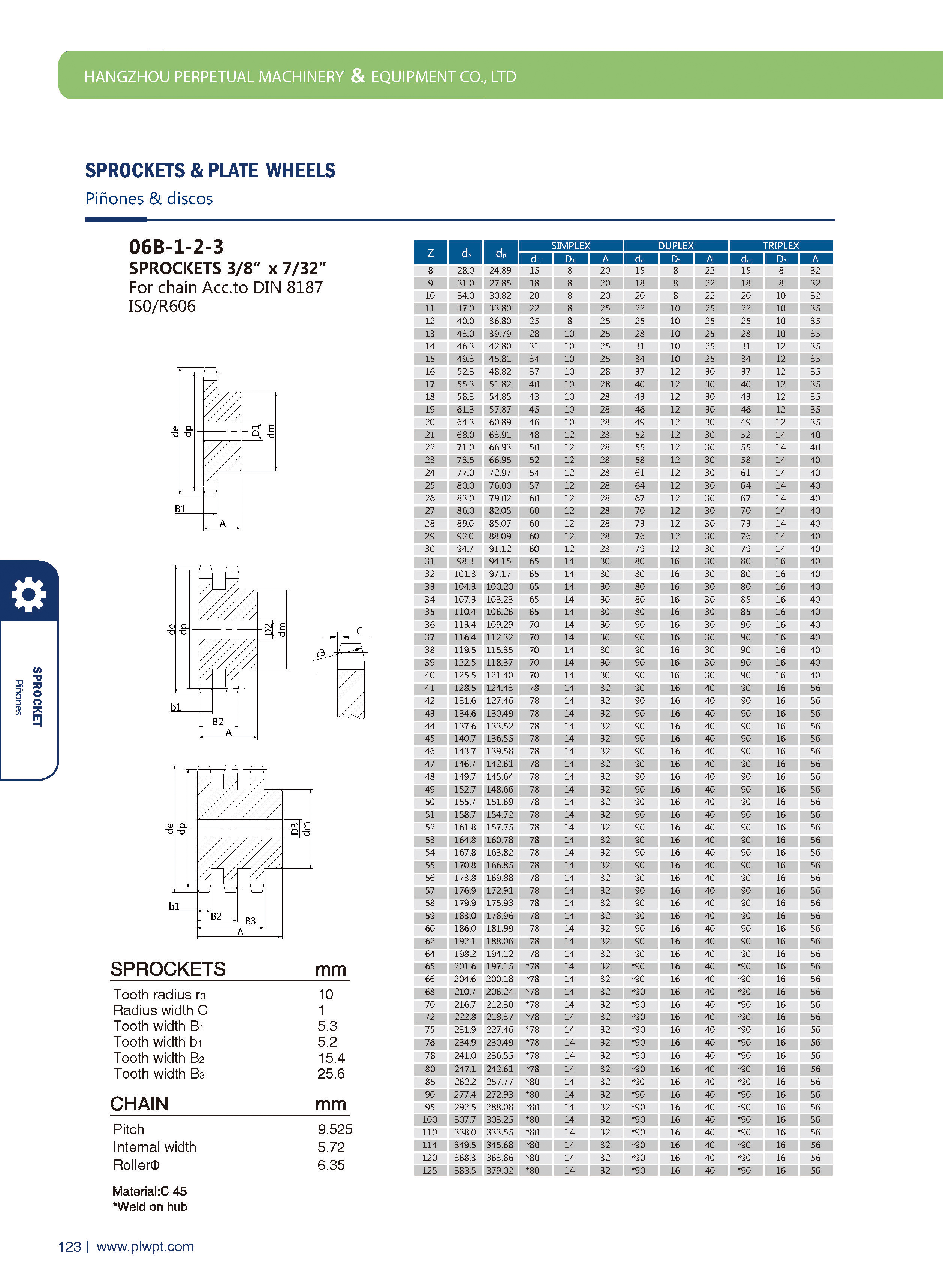

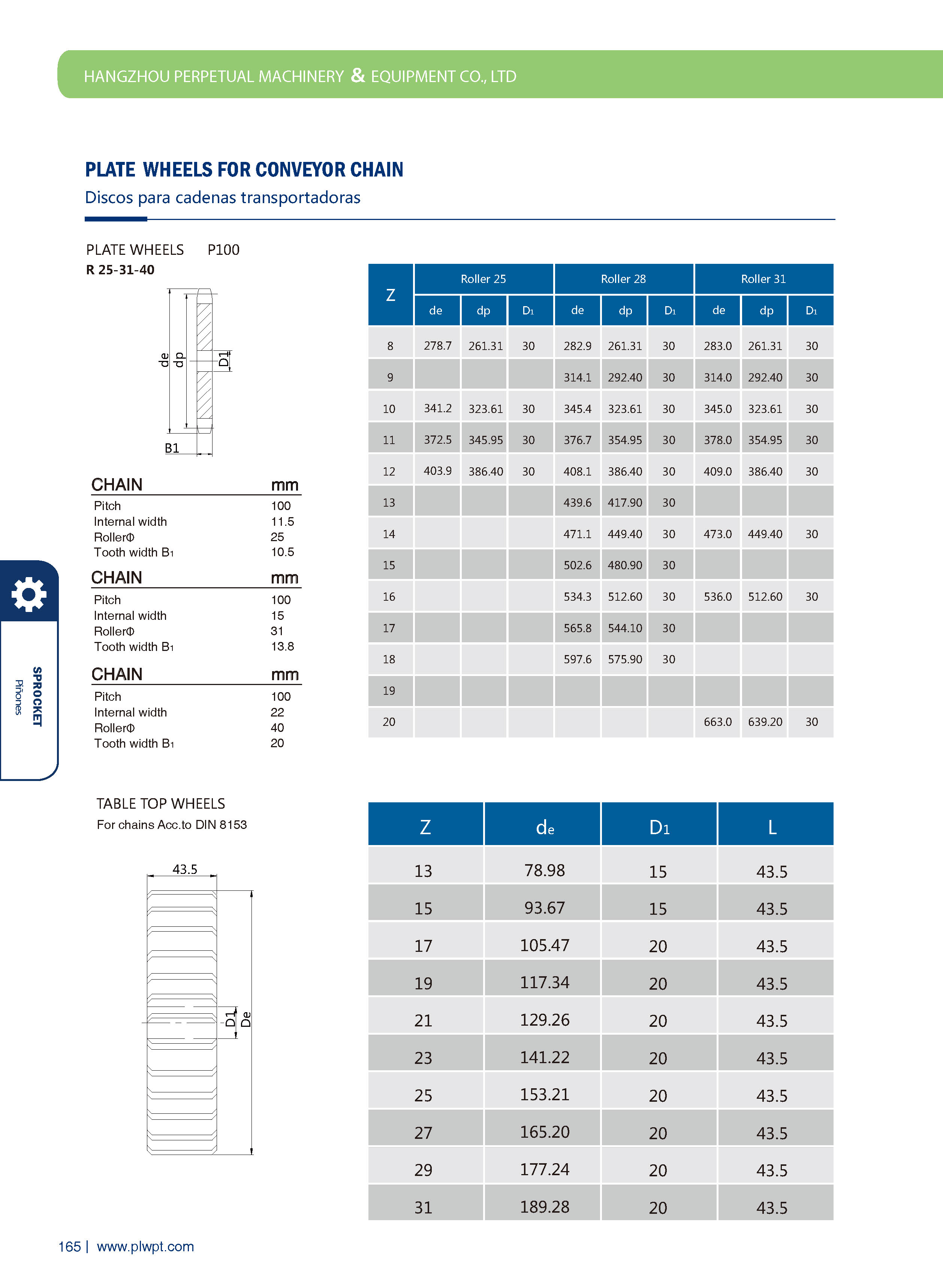

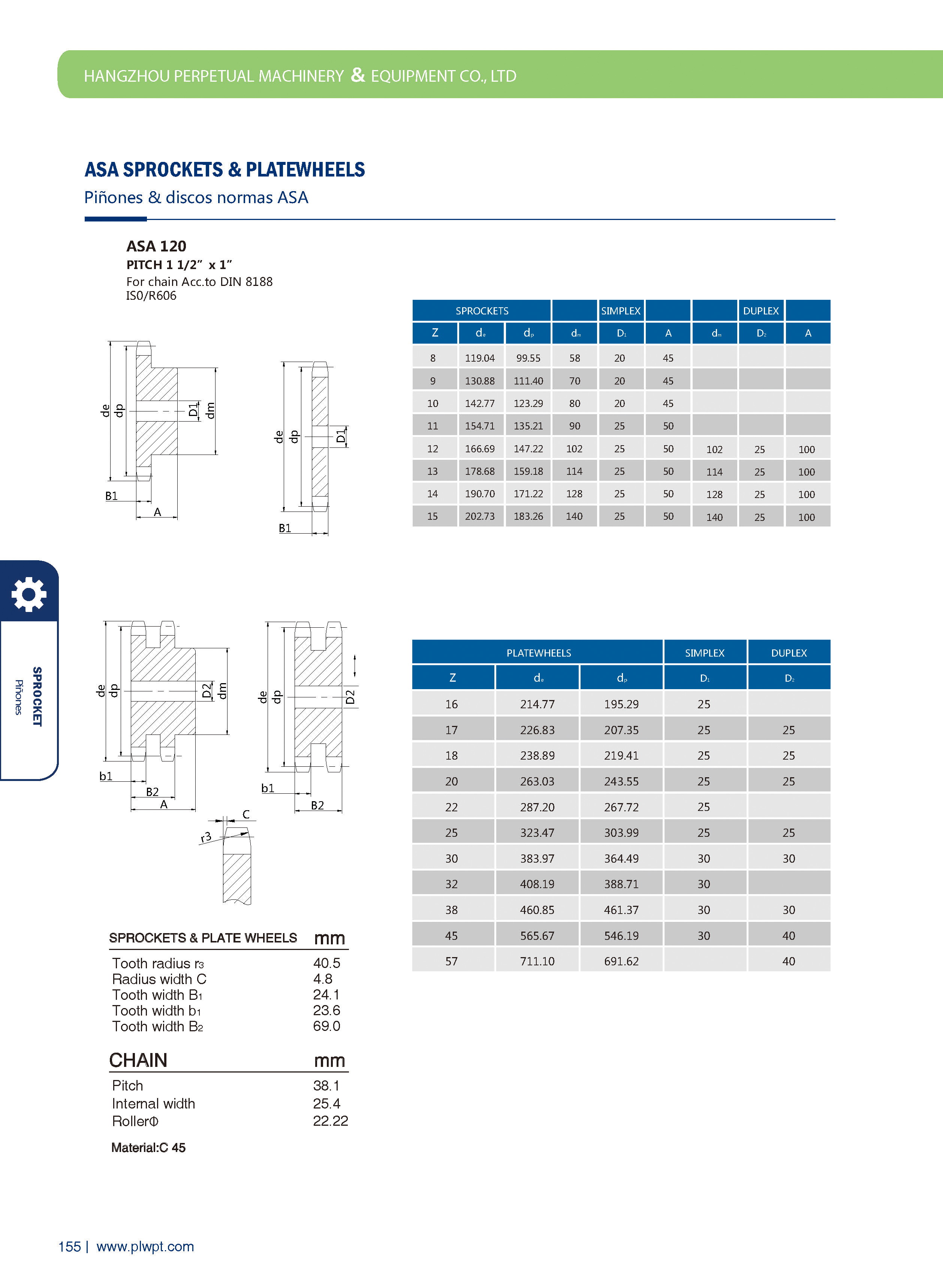

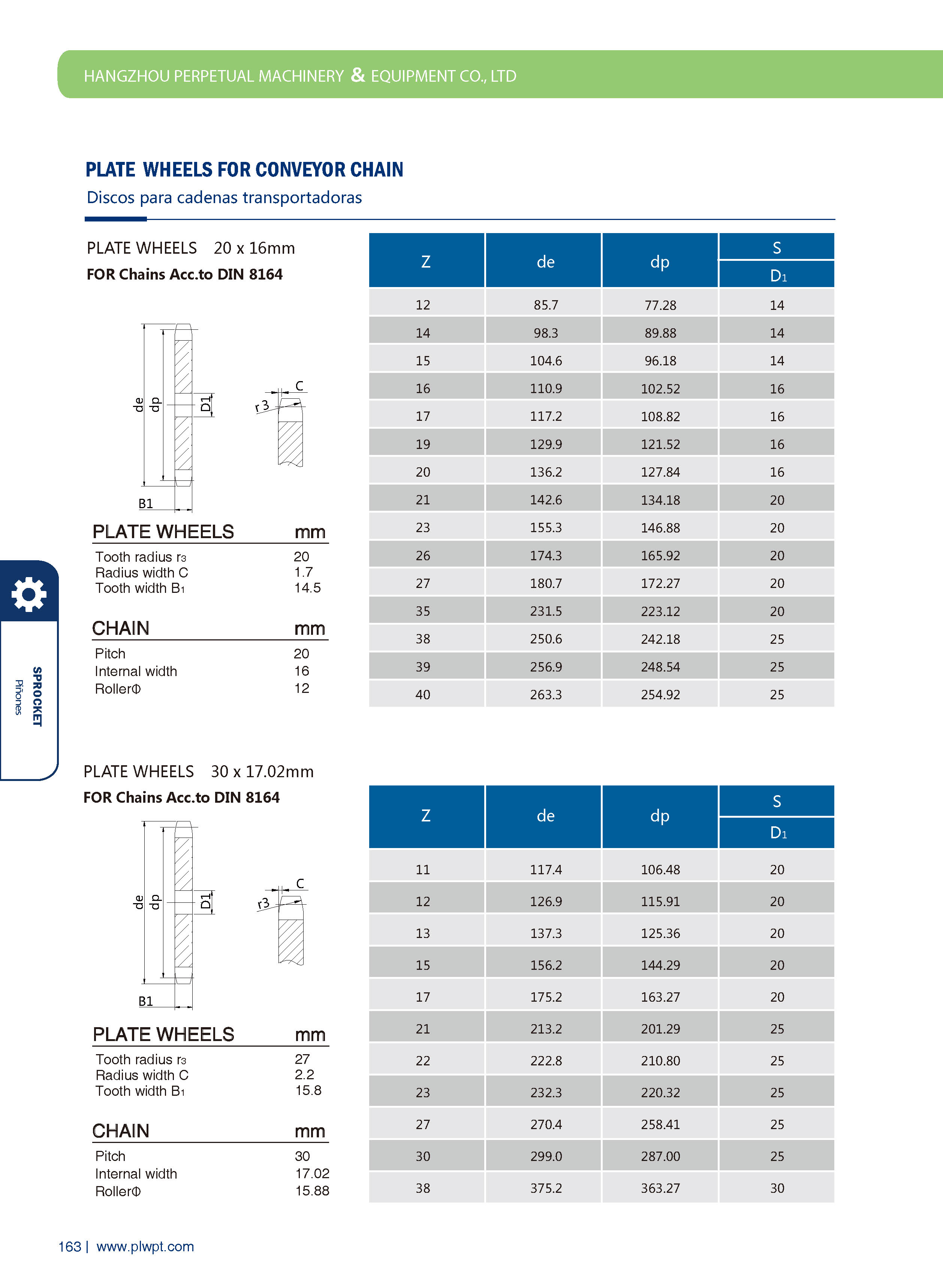

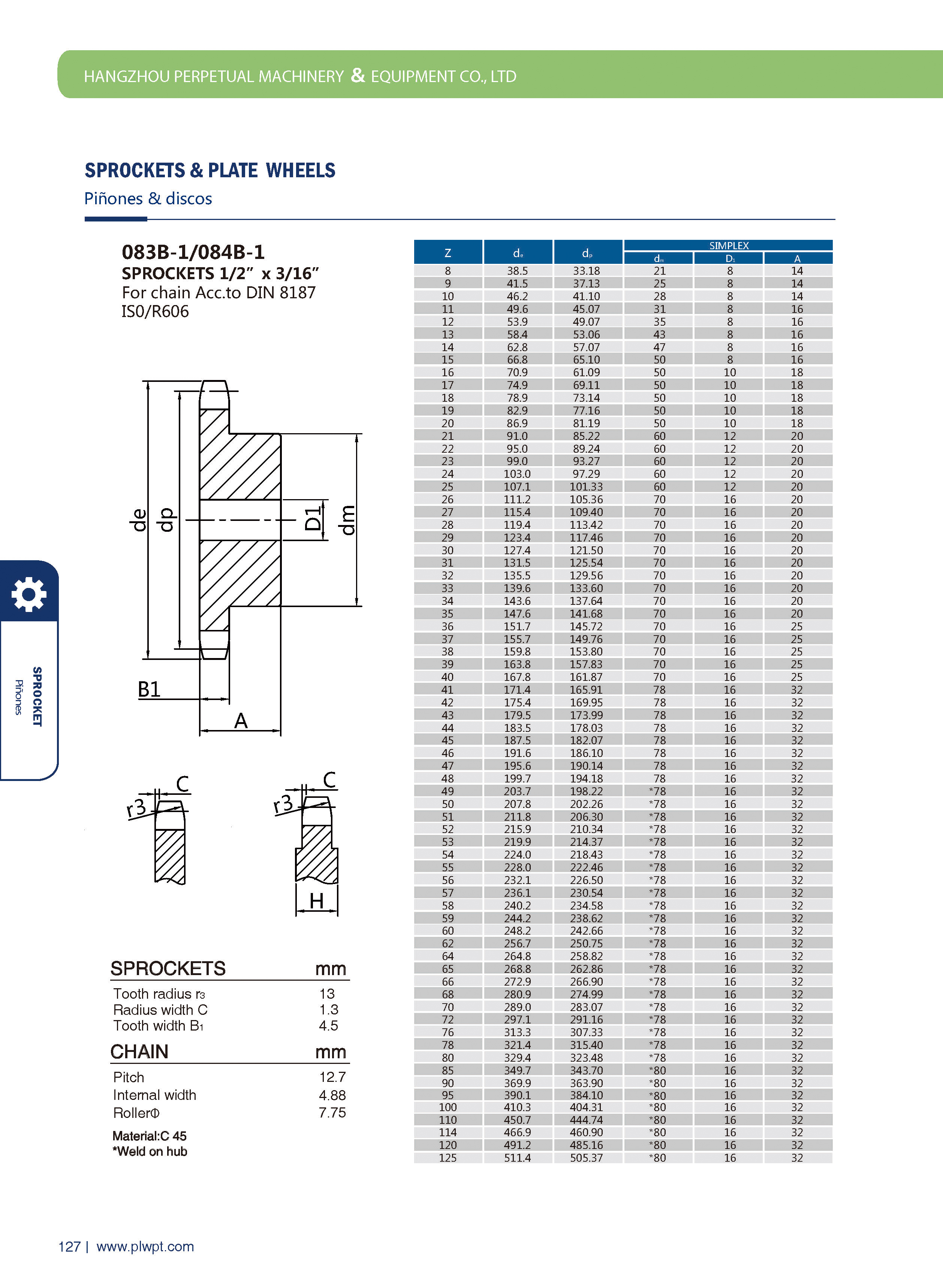

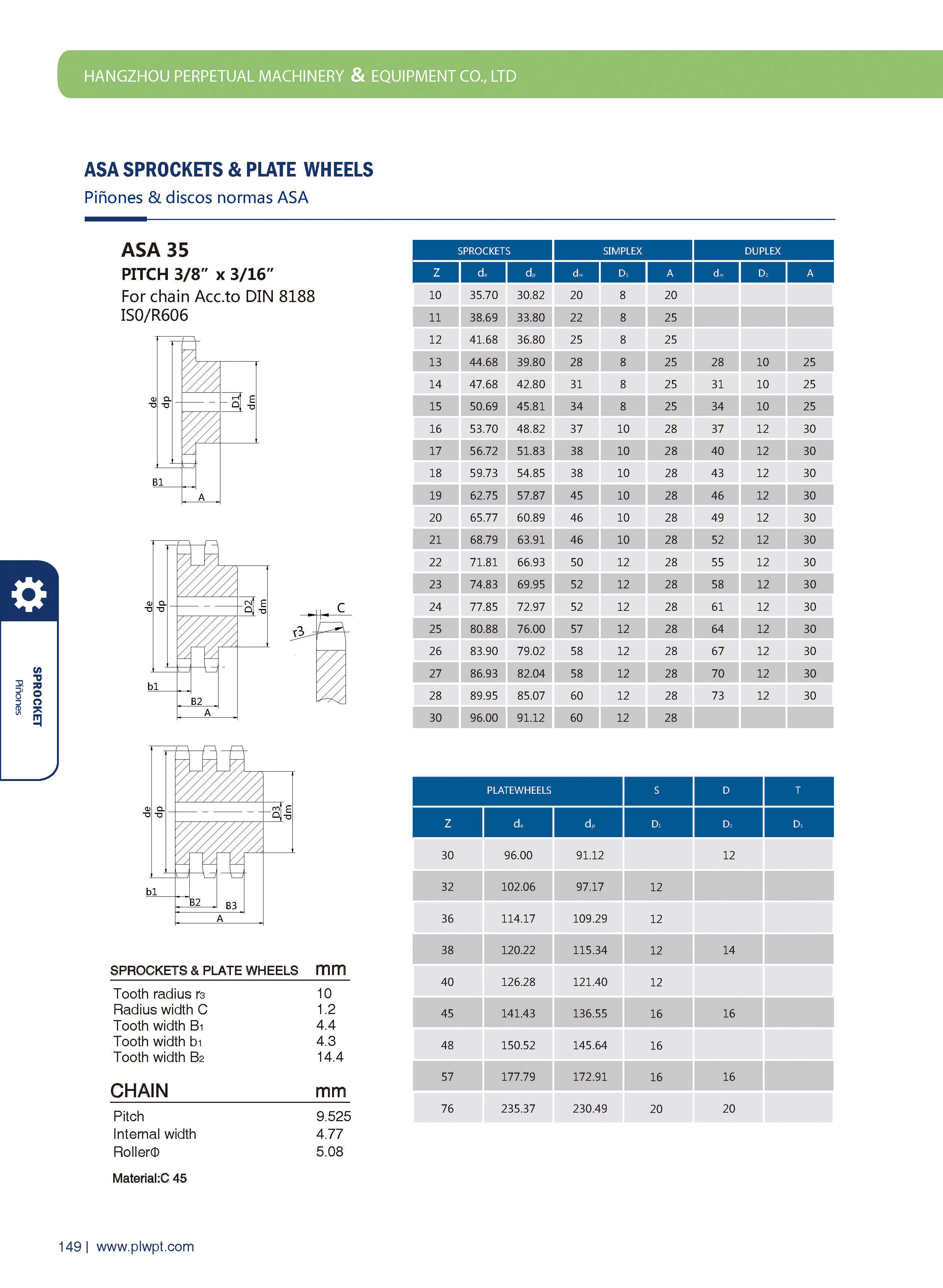

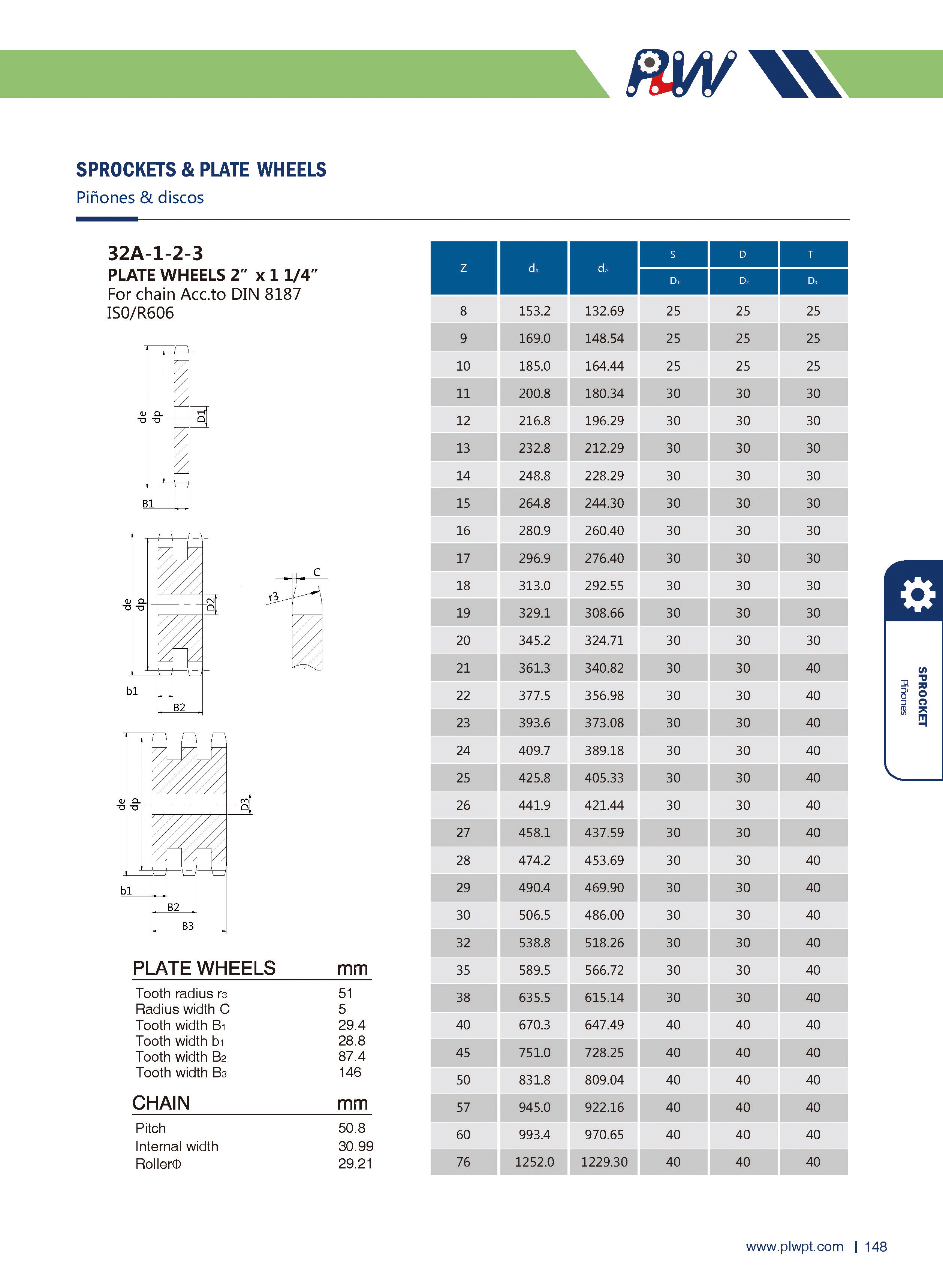

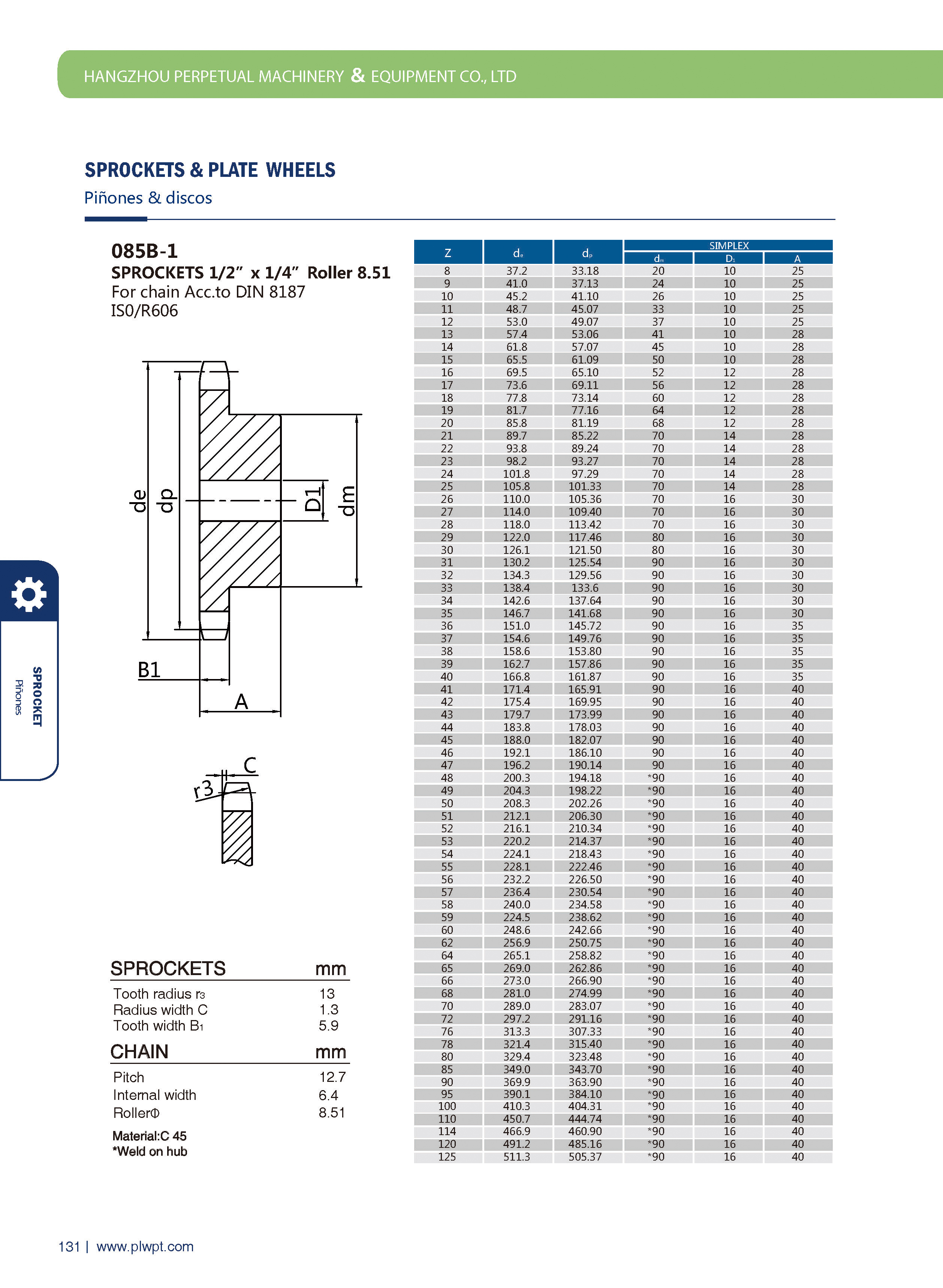

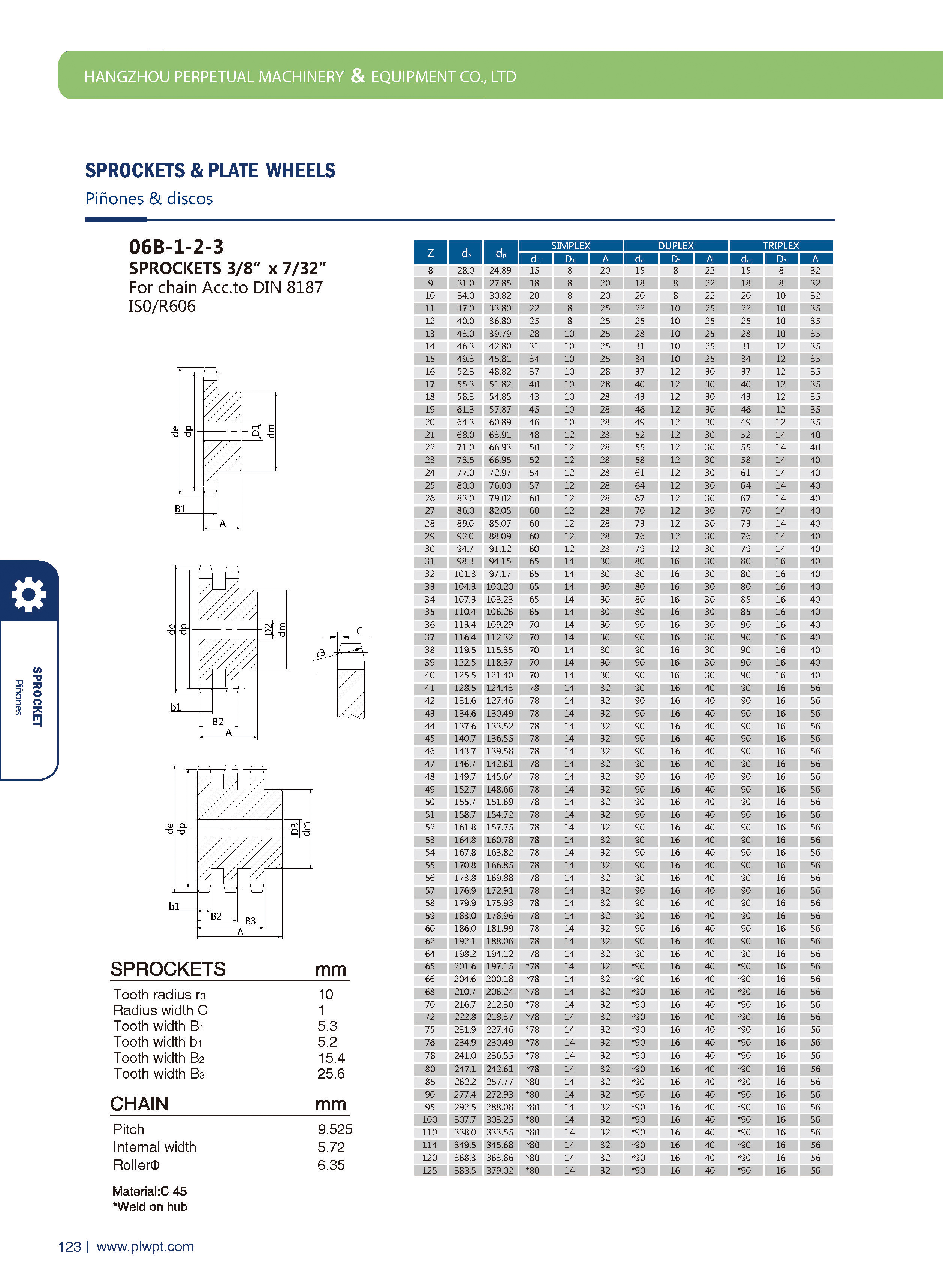

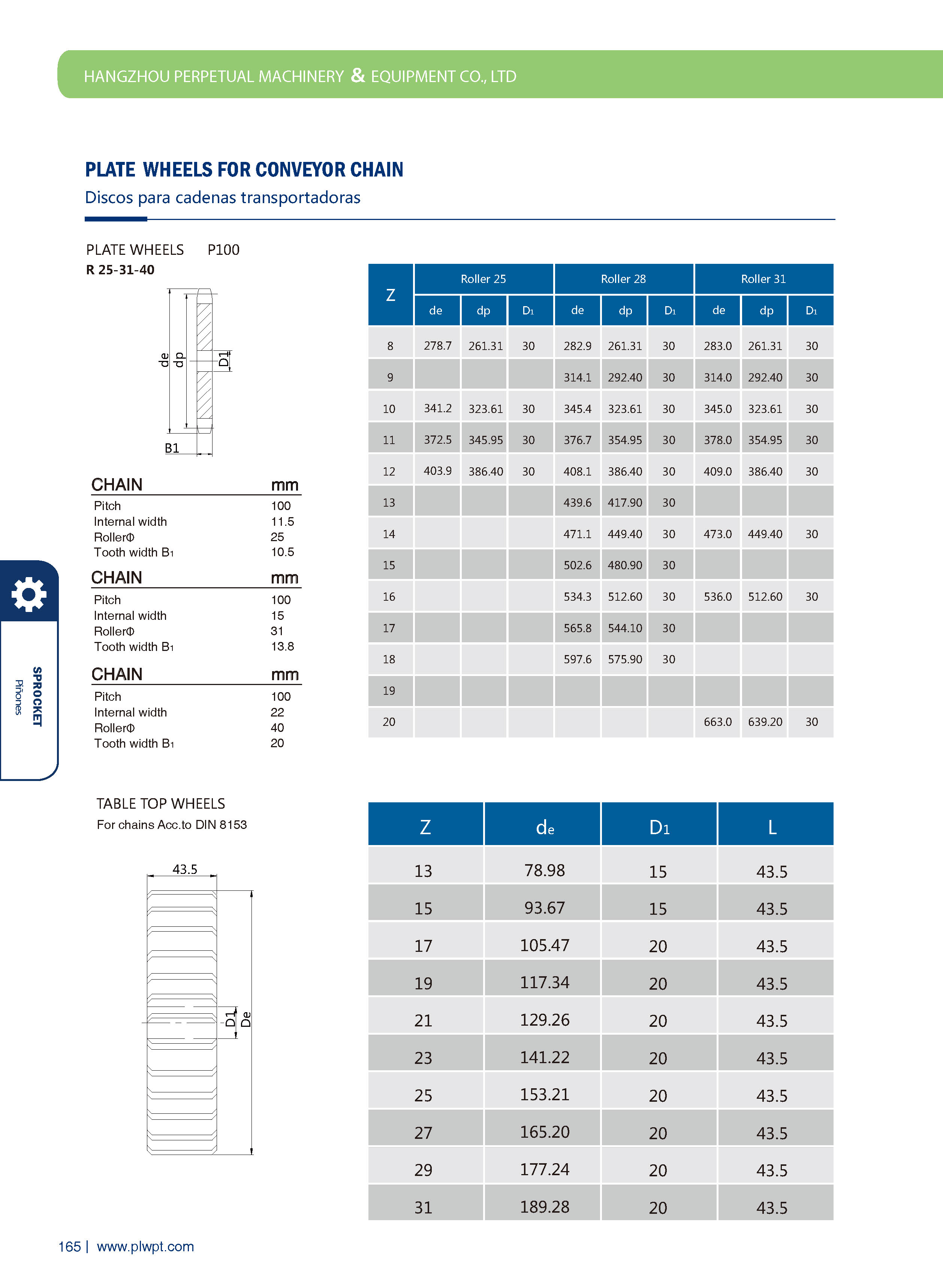

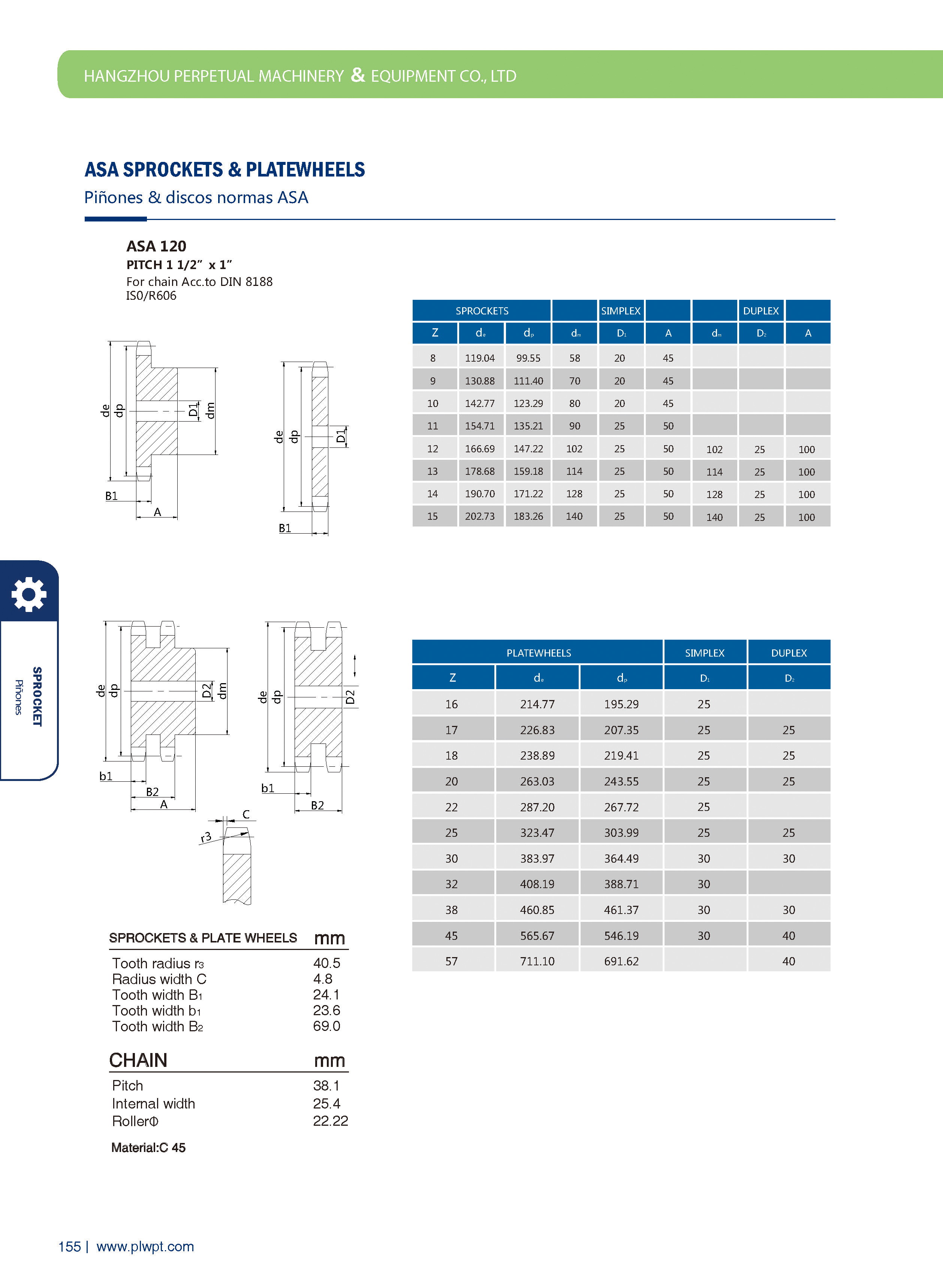

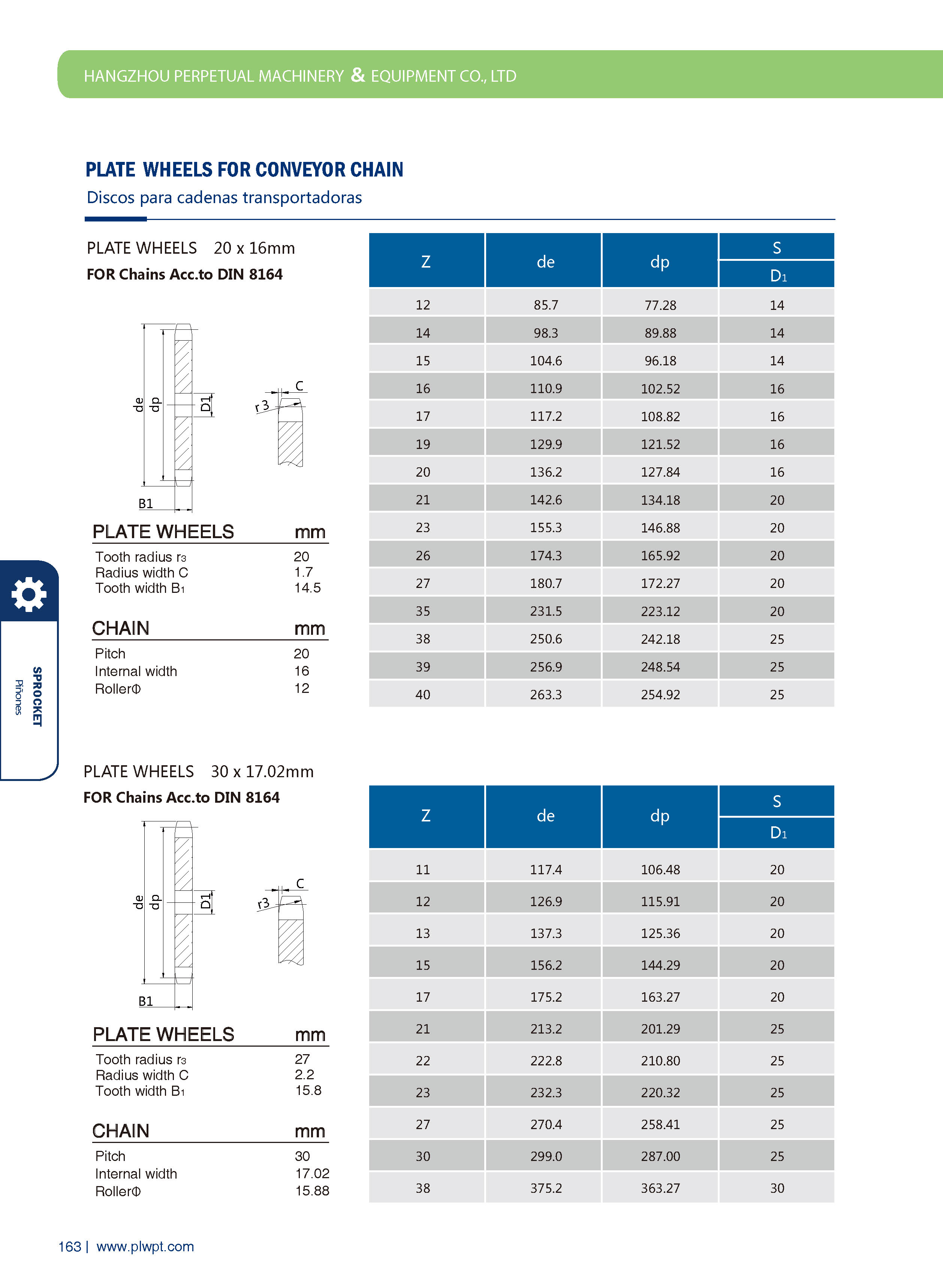

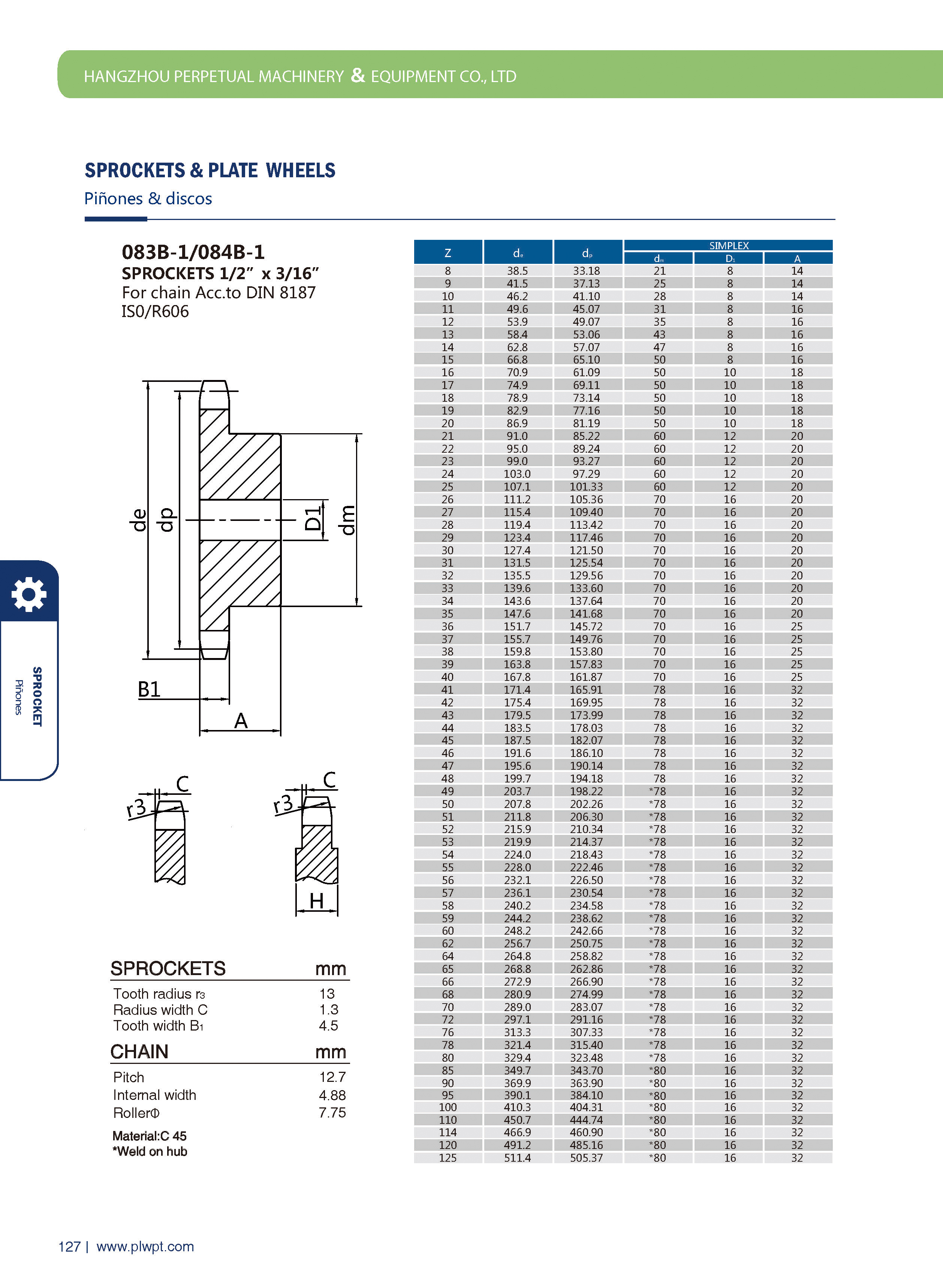

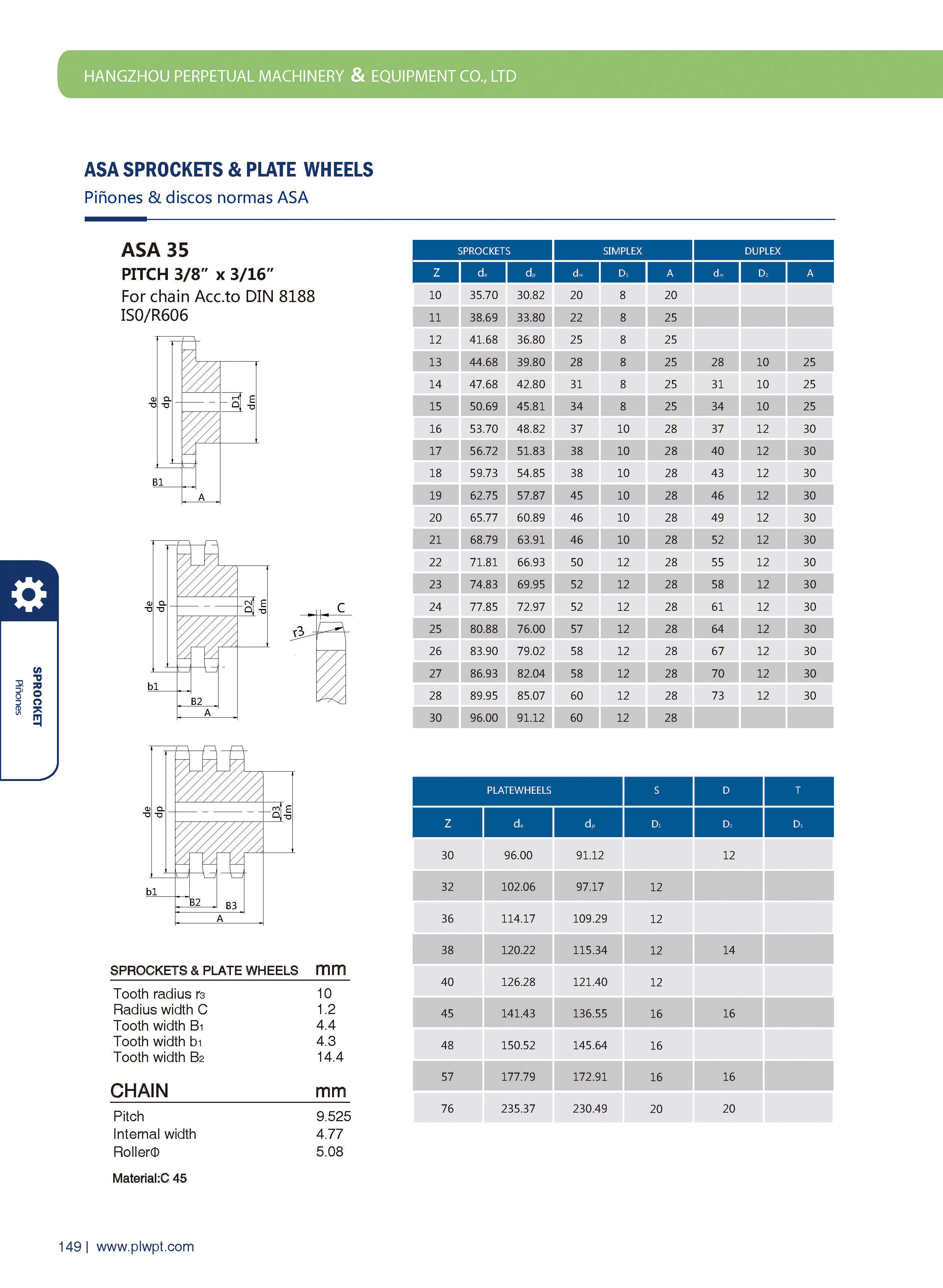

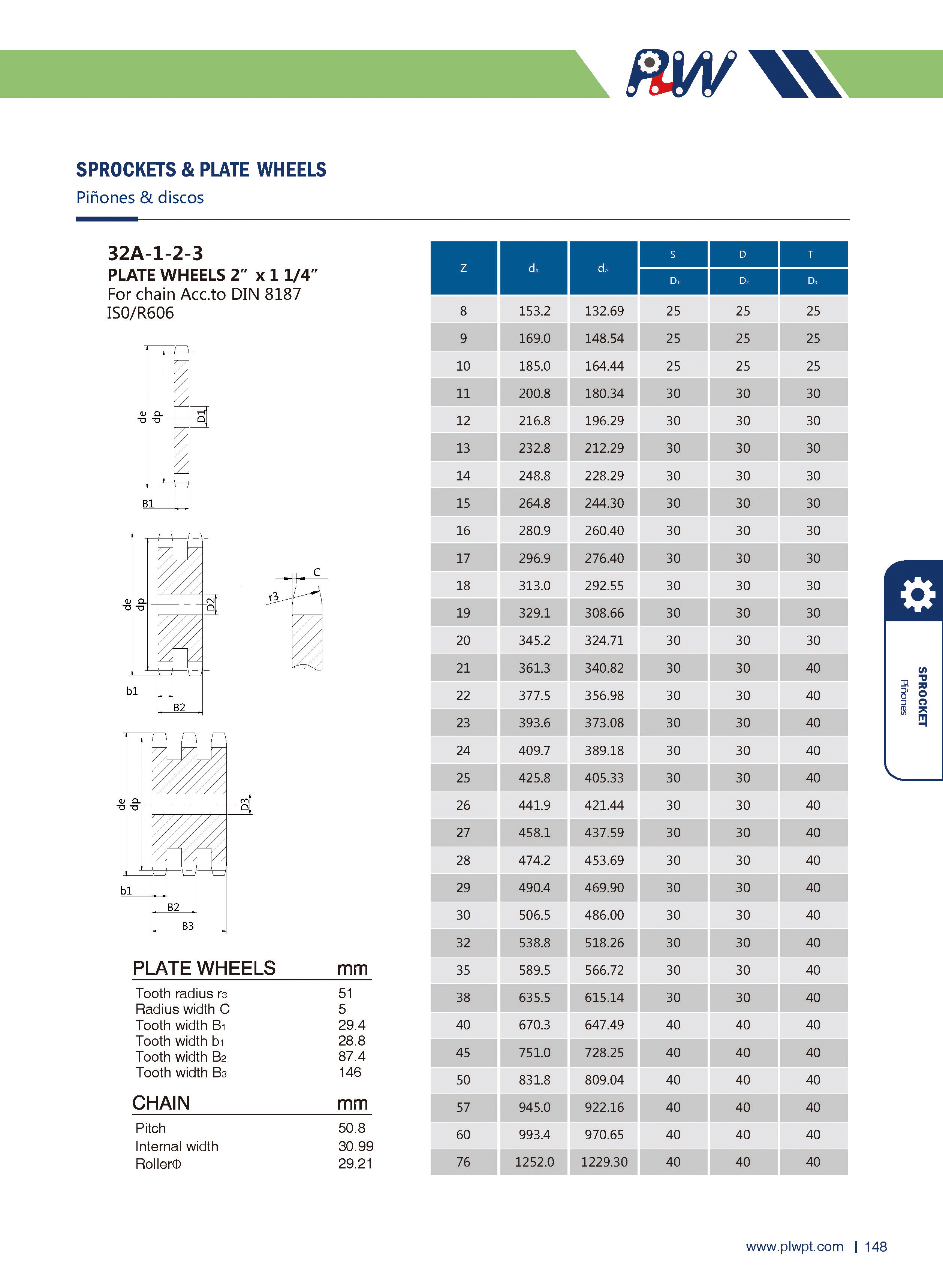

The Custom-Made Roller Chain Sprockets offer precise gear-to-chain engagement for optimal power transmission in industrial drive systems. Available in standard (ANSI, ISO, DIN) and custom designs, these sprockets are manufactured with CNC machining and heat treatment to ensure minimal wear and maximum efficiency.

Features

Global Standard Compliance:

ANSI B29.1: For North American roller chain systems (04B to 24A sizes).

ISO 606: For European metric chains (06B to 20B pitch).

JIS B1801: For Japanese industrial chains (25 to 200 series).

Material Options:

Carbon Steel (C45): Cost-effective for general industrial use (up to 1,000rpm).

Stainless Steel (304/316): Corrosion-resistant for food, marine, and chemical applications.

Alloy Steel (4140): Heat-treated (45-50HRC) for high-torque, high-speed drives (up to 3,000rpm).

Precision Machining: Laser-cut teeth with ±0.02mm profile accuracy reduce chain wear by 25% compared to standard sprockets.

Hub Configurations: Available in pilot bore, taper lock, and split hub designs for easy installation on shafts (10-200mm diameter).

Application

Power Transmission Systems: Matches with roller chains in gearboxes, reducers, and motor drives across all industries.

Conveyor Systems: Ensures smooth chain movement in belt conveyors, chain drives, and overhead monorails.

Agricultural Equipment: Used in tractor PTO drives, combine harvester chains, and irrigation system sprockets.

Renewable Energy: Supports wind turbine yaw drives and solar tracker mechanisms with corrosion-resistant designs.

Why Choose Us

Unlimited Customization: Capable of producing sprockets with 5-150 teeth, special tooth profiles, and non-standard bores.

Rapid Turnaround: 3-day lead time for standard sprockets (stocked sizes) and 10-day lead time for fully custom designs.

Quality Guarantee: 100% dimensional inspection using CMM machines and hardness testing for heat-treated components.

Engineering Support: Free CAD/CAM files and sprocket selection software to help customers optimize drive system performance.

English

Español

العربية

Français

Русский

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

አማርኛ

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Kiswahili

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

Հայերեն

עברית

Latine

Dansk

اردو

Shqip

বাংলা

Hrvatski

Afrikaans

Gaeilge

Eesti keel

Māori

සිංහල

नेपाली

Oʻzbekcha

latviešu

অসমীয়া

Aymara

Azərbaycan dili

Bamanankan

Euskara

Беларуская мова

भोजपुरी