WR78/WH78 Welded Steel Chains, Reliable And Long-Lasting Performance

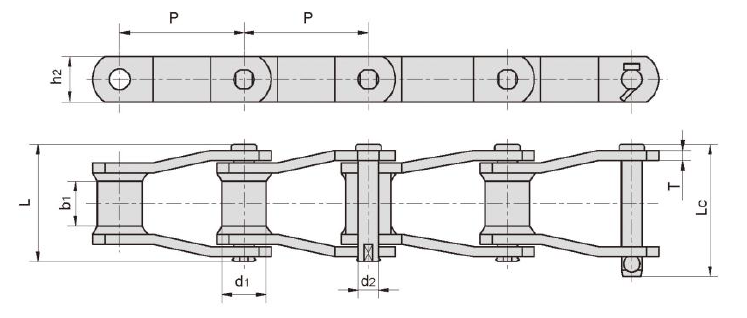

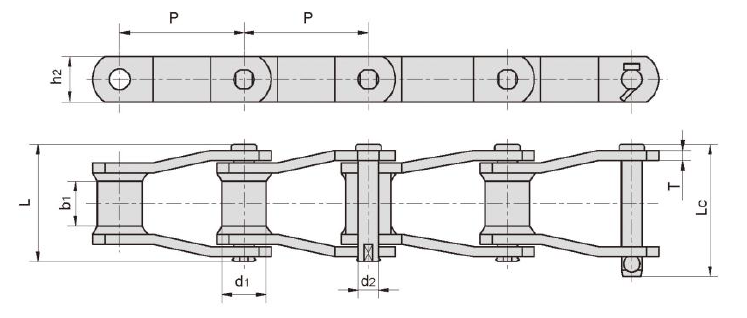

| CHAIN NO. | Pitch | Bush

diameter | Width

between

inner plates | Pin

diameter | Pin length | Plate depth | Plate

thickness | Ultimate

tensile

strength | Average

tensile

strength | Weight

per

meter |

| Cadena No | Paso | Diámetro

casquillo | Ancho

interior | Diámetro

pasador | Longitud

pasador | Altura

placas | Ancho

placas | Resis.

rotura | Resis

media

tracción | Peso

por

metro |

| P | d1

max | b

min | p

max | L

max | Lc

max | h2

max | T | Q

min | Qo | q |

| mm | mm | mm | mm | mm | mm | mm | mm | KN/LB | KN | kg/m |

WR78

WH78 | 66.27 | 22.9 | 28.4 | 12.78 | 73.0 | 79.3 | 28.4 | 6.4 | 93.4/21227

106.8/24273 | 102.7

117.5 | 6.20 |

WR82

WH82 | 78.10 | 31.5 | 31.8 | 14.35 | 80.0 | 86.0 | 31.8 | 6.4 | 100.1/22750

131.2/29818 | 110.1

144.3 | 7.98 |

WR106

WH106 | 152.40 | 37.1 | 41.2 | 19.13 | 103.0 | 111.0 | 38.1 | 9.7 | 169.0/38409

224.6/51045 | 185.9

247.0 | 10.56 |

WR110

WH110 | 152.40 | 32.0 | 46.7 | 19.13 | 107.7 | 115.5 | 38.1 | 9.7 | 169.0/38409

224.6/51045 | 185.9

247.0 | 10.40 |

WR111

WH111 | 120.90 | 37.1 | 57.2 | 19.13 | 116.8 | 124.5 | 38.1 | 9.7 | 169.0/38409

224.6/51045 | 185.9

247.0 | 12.72 |

WR124

WH124 | 101.60 | 37.1 | 41.2 | 19.13 | 103.0 | 110.0 | 38.1 | 9.7 | 169.0/38409

224.6/51045 | 185.9

247.0 | 12.38 |

WR124H

WH124H | 103.20 | 41.7 | 41.2 | 22.30 | 131.6 | 133.0 | 50.8 | 12.7 | 275.8/62682

355.9/80886 | 303.3

391.4 | 19.68 |

WR132

WH132 | 153.67 | 44.7 | 76.2 | 25.48 | 151.0 | 162.2 | 50.8 | 12.7 | 275.8/62682

378.1/85932 | 303.3

415.9 | 20.00 |

WR150

WH150 | 153.67 | 44.45 | 73.0 | 25.40 | 151.0 | 162.2 | 63.5 | 12.7 | 620/140907 | 682 | 20.50 |

WR155

WH155 | 153.67 | 44.45 | 73.0 | 28.57 | 164.0 | 176.0 | 63.5 | 12.7 | 820/186361 | 902 | 20.70 |

WR157

WH157 | 153.67 | 44.45 | 76.2 | 28.57 | 164.0 | 176.0 | 63.5 | 15.9 | 820/186361 | 902 | 20.80 |

Precision Welded Steel Chains for Machinery Applications

Product Introduction

Precision welded steel chains are engineered to deliver exceptional strength, durability, and dimensional accuracy for a wide range of heavy-duty machinery applications. Crafted from high-grade carbon steel or alloy steel, these chains undergo a rigorous precision welding process that ensures uniform joint integrity, eliminating weak points and enhancing load-bearing capacity.

Unlike conventional welded chains, our precision series features tight tolerance control on pitch, link plate thickness, and pin diameter, guaranteeing smooth engagement with sprockets and minimizing wear even in high-speed or high-torque operating conditions. The welding seams are meticulously treated—deburred, heat-treated, and surface-finished—to resist corrosion, fatigue, and impact, making them ideal for harsh industrial environments such as manufacturing lines, material handling systems, construction machinery, agricultural equipment, and automotive production facilities.

Key features of our precision welded steel chains include:

High Precision & Consistency

Computer-controlled welding and machining processes ensure consistent pitch and link geometry, reducing vibration and noise during operation, and extending the service life of both the chain and mating components.

Superior Strength & Durability

Heat-treated link plates and pins enhance tensile strength and wear resistance, allowing the chain to withstand heavy loads, shock loads, and continuous cyclic operations without deformation or failure.

Corrosion & Wear Resistance

Optional surface treatments—including galvanization, zinc-plating, or oil immersion—provide enhanced protection against rust, abrasion, and chemical exposure, adapting to dry, wet, or dusty working conditions.

Versatile Customization

We offer customizable solutions to meet specific application requirements, including varying chain pitches, link configurations, attachment types (e.g., K1, K2, A1, A2 attachments), and special coatings. Custom lengths and connection components are also available for seamless integration into existing machinery.

Easy Maintenance & Installation

Designed for hassle-free installation and minimal maintenance, these chains require only periodic lubrication to maintain optimal performance, reducing downtime and operational costs for end-users.

Our precision welded steel chains comply with international standards such as ISO, ANSI, and DIN, ensuring compatibility with global machinery designs and meeting the strict quality requirements of industrial manufacturers. Whether for conveyor systems, lifting equipment, or power transmission units, these chains deliver reliable, long-lasting performance that maximizes productivity and minimizes total cost of ownership.

Choose our precision welded steel chains for your machinery applications—where precision meets power, and durability meets efficiency.

English

Español

العربية

Français

Русский

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

አማርኛ

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Kiswahili

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

Հայերեն

עברית

Latine

Dansk

اردو

Shqip

বাংলা

Hrvatski

Afrikaans

Gaeilge

Eesti keel

Māori

සිංහල

नेपाली

Oʻzbekcha

latviešu

অসমীয়া

Aymara

Azərbaycan dili

Bamanankan

Euskara

Беларуская мова

भोजपुरी