Roller Chains with Straight Side Plates (A Series)

As a staple in precision industrial power transmission, the A Series Roller Chains with Straight Side Plates are engineered to deliver consistent performance, easy maintenance, and broad adaptability across medium-load applications. Adhering strictly to ANSI B29.1 standards, this series features a classic straight side plate design—distinguished by its parallel, flat side plate structure—that ensures uniform load distribution, precise sprocket meshing, and compatibility with standard industrial machinery, making it a reliable choice for general mechanical transmission systems.

Core Advantages: Straight Side Plate Design & Precision Performance

The defining feature of the A Series is its straight side plate construction, a design that sets it apart from curved or offset side plate chains. Crafted from high-grade carbon steel (1045) or alloy steel, the straight side plates are precision-stamped and heat-treated to maintain flatness and structural integrity, ensuring even load distribution across each link. This eliminates stress concentration points, reduces premature wear, and enables smooth, stable meshing with standard sprockets—critical for maintaining transmission accuracy in medium-speed, medium-load operations (up to 350 rpm).

Precision engineering is integrated into every component to enhance durability and efficiency. Rollers and pins are manufactured with tight dimensional tolerances (±0.02mm) and undergo carburizing, quenching, and tempering processes, achieving a surface hardness of HRC 58-62 for wear resistance and a tough core (HRC 38-42) to resist impact. The bushings are seamlessly fitted between rollers and pins, minimizing friction and power loss, while the straight side plate design simplifies assembly and disassembly—supporting both cottered and spring clip connections for flexible installation and maintenance.

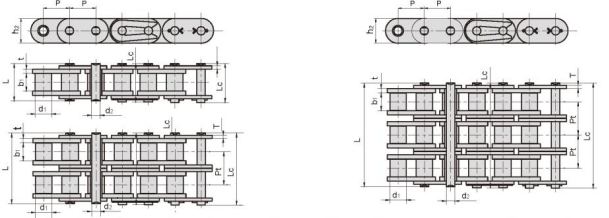

Versatility and cost-effectiveness further elevate the A Series’ value. Available in single-strand, double-strand, and triple-strand configurations, it covers working load capacities from 8kN to 110kN, adapting to diverse industrial scenarios. Optional surface treatments—including black oxide, zinc plating, and nickel plating—provide corrosion resistance for use in moderately harsh environments, while the standard ANSI dimensions ensure universal compatibility with existing machinery, reducing replacement costs and downtime.

Structural Excellence & Operational Reliability

The A Series is designed for consistent performance in everyday industrial conditions. Its straight side plate structure ensures lateral stability, preventing chain deflection during operation and maintaining precise alignment with sprockets. The optimized roller-bushing assembly reduces contact pressure, extending service life under continuous operation, while the heat-treated components withstand temperature fluctuations from -20℃ to 120℃—adapting to both indoor and outdoor applications.

Safety and maintainability are prioritized in the design. The smooth, straight edges of the side plates minimize debris accumulation and reduce the risk of jamming, while the predictable wear pattern allows for proactive maintenance scheduling. Whether using cottered pins for permanent connections or spring clips for quick adjustments, the chain supports on-site maintenance without specialized tools, ensuring minimal operational interruptions.

Technical Specifications

| Parameter | Details |

| Model Series | A Series Roller Chains with Straight Side Plates (ANSI B29.1, ISO 606 compliant) |

| Material | High-grade carbon steel (1045) or alloy steel; straight side plates (precision-stamped); optional 304 stainless steel |

| Heat Treatment | Carburizing, quenching, and tempering (rollers/pins: HRC 58-62; side plates: HRC 40-45) |

| Connection Type | Cottered type (permanent) or spring clip type (quick adjustment); compatible with standard ANSI sprockets |

| Pitch Size | 12.7mm (1/2") to 31.75mm (1-1/4") (short pitch, ANSI standard) |

| Working Load Capacity | 8kN - 110kN (single-strand to triple-strand configurations) |

| Max Operating Speed | Up to 350 rpm (depending on pitch, load, and connection type) |

| Surface Treatment | Black oxide, zinc plating, nickel plating (anti-corrosion, wear-resistant) |

| Certifications | ANSI B29.1, ISO 606, SGS |

Application Scenarios

The A Series Roller Chains with Straight Side Plates are widely utilized in general industrial transmission systems, offering reliable performance across diverse sectors:

General Machinery: Suitable for motors, reducers, pumps, compressors, and gearboxes, providing precise power transmission in standard industrial equipment.

Automotive & Motorcycle Industry: Used in auxiliary systems (e.g., water pumps, oil pumps) and small transmission mechanisms, with straight side plates ensuring stable operation.

Light Industrial Equipment: Ideal for packaging machines, printing presses, textile machinery, and woodworking equipment, supporting medium-speed, medium-load operations.

Agricultural Machinery: Compatible with small to medium agricultural equipment (e.g., small harvesters, feed mixers), resisting moderate dust and load fluctuations.

Material Handling: Applied in light to medium-duty conveyors, palletizers, and small hoists, with universal compatibility and easy maintenance.

Quality Assurance & After-Sales Support

The A Series adheres to strict ANSI B29.1 and ISO 606 standards, with full-process quality control from raw material inspection to final assembly. Each batch undergoes rigorous testing, including dimensional accuracy checks, tensile strength tests, wear resistance tests, and meshing performance tests, ensuring consistent reliability in long-term operation. This commitment to quality minimizes equipment downtime and maintenance costs for customers.

We provide comprehensive after-sales support, including technical consultation on chain selection, installation guidance, maintenance training, and customized length solutions. Our team of transmission experts helps optimize chain performance for specific applications, and all A Series products come with a quality warranty, ensuring customers’ investment is fully protected.

Choose the A Series Roller Chains with Straight Side Plates for reliable, precise, and cost-effective power transmission. It’s the trusted core component for your general industrial machinery, designed to perform consistently in everyday operations.

English

Español

العربية

Français

Русский

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

አማርኛ

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Kiswahili

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

Հայերեն

עברית

Latine

Dansk

اردو

Shqip

বাংলা

Hrvatski

Afrikaans

Gaeilge

Eesti keel

Māori

සිංහල

नेपाली

Oʻzbekcha

latviešu

অসমীয়া

Aymara

Azərbaycan dili

Bamanankan

Euskara

Беларуская мова

भोजपुरी