Product Description

Imagine a production floor where the air is humid, scented with cleaning agents, and the machinery is constantly subjected to high-pressure water jets. In this environment, a standard carbon steel chain is a liability—a ticking clock of rust and downtime. Our Stainless Steel Roller Chains are designed to be the antidote to that stress. When you run your hand across our links, you don't feel the greasy, heavy residue of industrial oil. Instead, you feel the smooth, cool, and pristine surface of surgical-grade steel. It is a product that looks as clean as the facility it serves, reflecting light with a satin finish that signals pure mechanical quality.

We were inspired by the daily battles of the food and beverage industry, where the margin for error is zero and the cost of contamination is catastrophic. This chain isn't just about moving a belt; it's about the silence of a perfectly articulated drive system and the rhythmic "click" of precision-ground rollers meeting their sprockets without a hint of friction. By switching to our stainless steel series, you are choosing a silent partner that won't flake, won't rust, and won't compromise your product's purity. It turns a high-maintenance headache into a "set-and-forget" asset, allowing you to focus on your throughput while we handle the harsh chemistry of your environment.

Product Features and Highlights

The core value of our stainless steel series lies in its specialized metallurgical properties and manufacturing precision:

Certified 304/316 Grade Alloys: We use only verified raw materials. Grade 304 offers excellent general corrosion resistance, while Grade 316 is optimized for high-chloride or marine environments where acid resistance is a critical requirement.

Fully Seamless Roller Construction: Unlike folded rollers that can harbor bacteria in their seams, our rollers are cold-drawn and seamless. This prevents the buildup of organic matter and makes high-pressure steam cleaning 100% effective.

Vacuum-Heat Treatment: Our components undergo heat treatment in a vacuum environment to ensure that the protective chromium oxide layer remains intact. This maximizes the chain's ability to "self-heal" its surface after minor abrasions.

Non-Magnetic Properties: For sensitive electronics manufacturing or pharmaceutical sorting lines, our 316-grade chains offer non-magnetic operation, preventing interference with delicate sensors and instrumentation.

Material Selection & Environmental Adaptation

Choosing the right stainless steel grade is essential for the longevity of your system. Our E-E-A-T focused engineering team helps you match the material to the chemical reality of your production floor.

Grade 304 (Standard Stainless): The most popular choice for food packaging and bottling. It provides exceptional resistance to water and mild detergents. It is the cost-effective "gold standard" for hygiene.

Grade 316 (Acid-Resistant): Essential for meat processing (where salt is prevalent) or chemical plants. The addition of molybdenum makes it immune to the "pitting" corrosion caused by chlorides and industrial acids.

Grade 600 Series (Hardened Stainless): For applications requiring the corrosion resistance of stainless but the wear life closer to carbon steel. This material undergoes precipitation hardening, making the pins significantly more resistant to elongation.

Temperature Resilience: Our chains operate comfortably from -40°C in flash freezers up to +400°C in industrial ovens, maintaining their structural integrity and tensile strength throughout the thermal cycle.

Manufacturing Excellence & Quality Control

We understand that in the pharmaceutical and food industries, "good enough" is never an option. Our manufacturing process is a rigorous series of checks designed to ensure absolute reliability.

Precision Centerless Grinding: The pins and bushes are ground to a mirror finish. This reduces the initial "break-in" wear and ensures that the chain maintains its pitch accuracy even in the absence of heavy lubrication.

Automated Link Assembly: Using high-speed Swiss-engineered assembly lines, we ensure that every riveting point is identical. This eliminates the "stiff links" that cause vibration and premature sprocket wear.

Nitric Acid Passivation: Every chain undergoes a chemical passivation process that removes any surface impurities and thickens the protective oxide layer, significantly boosting its anti-rust performance.

Pre-Loading Protocol: We apply a rigorous pre-stretch to every chain before shipping. This stabilizes the internal components, ensuring that your automated indexing remains perfectly synchronized from the first hour of operation.

Application Use-Cases for Critical Environments

Our Stainless Steel Roller Chains are the trusted choice for industries where traditional drive systems fail due to environmental stress.

Industrial Bakeries: Navigating high-heat proofers and ovens where grease-based lubricants cannot be used due to smoke and contamination risks.

Pharmaceutical Labs: Operating in cleanrooms for vaccine packaging and pill sorting where particulate matter and magnetism must be strictly controlled.

Seafood & Meat Processing: Standing up to the high-salinity and high-moisture environments that would corrode a standard chain within weeks.

Chemical Synthesis: Moving materials through acidic wash-baths and sterilization tunnels where standard metals would undergo rapid oxidation.

Technical Specifications & Parameter Table

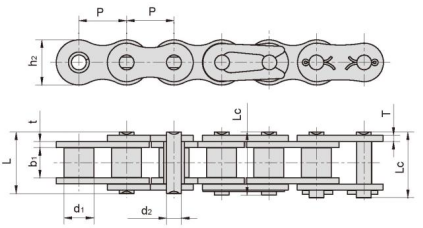

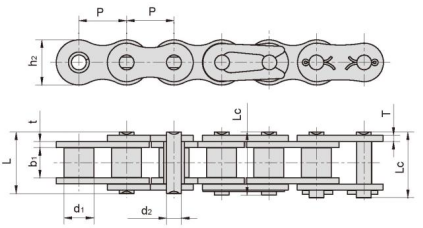

Our Stainless Steel Roller Chains are available in both ANSI (American Standard) and BS/DIN (British/European Standard). These parameters represent the precision tolerance required for seamless integration into high-speed automation.

| CHAIN NO. | Pitch | Roller

diameter | between

inner plates | Pin

diameter | Pin length | Inner

Plate

depth | Plate

thickness | Breaking

load | Weight

per

meter |

| Cadena No | Paso | Diámetro

rodillo | Ancho

interior | Diámetro

pasador | Longitud

pasador | Altura

placas | Ancho

placas | Carga

rotura | Peso

por

metro |

| P | d1

max | b1

min | d2

max | L

max | Lc

max | h2

max | t/T

max | Q | q |

| mm | mm | mm | mm | mm | mm | mm | mm | kN/LB | kg/m |

| *25SS | 6.350 | 3.30 | 3.18 | 2.31 | 7.9 | 8.40 | 6.00 | 0.80 | 2.5/568 | 0.15 |

| *35SS | 9.525 | 5.08 | 4.77 | 3.58 | 12.4 | 13.17 | 9.00 | 1.30 | 5.5/1250 | 0.33 |

| 40SS | 12.700 | 7.95 | 7.85 | 3.96 | 16.6 | 17.80 | 12.00 | 1.50 | 9.6/2182 | 0.63 |

| 41SS | 12.700 | 7.77 | 6.25 | 3.58 | 13.75 | 15.00 | 9.91 | 1.30 | 6.0/1360 | 0.46 |

| 50SS | 15.875 | 10.16 | 9.40 | 5.08 | 20.7 | 22.20 | 15.09 | 2.03 | 15.2/3455 | 1.03 |

| 60SS | 19.050 | 11.91 | 12.57 | 5.94 | 25.9 | 27.70 | 18.00 | 2.42 | 21.7/4932 | 1.51 |

| 80SS | 25.400 | 15.88 | 15.75 | 7.92 | 32.7 | 35.00 | 24.00 | 3.25 | 38.9/8841 | 2.62 |

| 100SS | 31.750 | 19.05 | 18.90 | 9.53 | 40.4 | 44.70 | 30.00 | 4.00 | 60.0/13636 | 3.94 |

| 120SS | 38.100 | 22.23 | 25.22 | 11.10 | 50.3 | 54.30 | 35.70 | 4.80 | 72.5/16477 | 5.72 |

| 140SS | 44.450 | 25.40 | 25.22 | 12.70 | 54.4 | 59.00 | 41.0 | 5.60 | 94.0/21363 | 7.70 |

| 04BSS | 6.000 | 4.00 | 2.80 | 1.85 | 6.80 | 7.80 | 5.00 | 0.60 | 2.0/455 | 0.11 |

| 05BSS | 8.000 | 5.00 | 3.00 | 2.31 | 8.20 | 8.90 | 7.10 | 0.80 | 3.5/795 | 0.20 |

| #06BSS | 9.525 | 6.35 | 5.72 | 3.28 | 13.15 | 14.10 | 8.20 | 1.30 | 6.2/1409 | 0.41 |

| 08BSS | 12.700 | 8.51 | 7.75 | 4.45 | 16.7 | 18.20 | 11.80 | 1.60 | 12.0/2727 | 0.70 |

| 10BSS | 15.875 | 10.16 | 9.65 | 5.08 | 19.5 | 20.90 | 14.70 | 1.70 | 14.5/3295 | 0.94 |

| 12BSS | 19.050 | 12.07 | 11.68 | 5.72 | 22.5 | 24.20 | 16.00 | 1.85 | 18.5/4205 | 1.16 |

| 16BSS | 25.400 | 15.88 | 17.02 | 8.28 | 36.1 | 37.40 | 21.00 | 4.15/3.1 | 40.0/9091 | 2.73 |

| 20BSS | 31.750 | 19.05 | 19.56 | 10.19 | 41.3 | 45.00 | 26.40 | 4.5/3.5 | 59.0/13409 | 3.73 |

| 24BSS | 38.100 | 25.40 | 25.40 | 14.63 | 53.4 | 57.80 | 33.20 | 6.0/4.8 | 104.0/25454 | 7.20 |

| 32BSS | 50.800 | 29.21 | 30.99 | 17.81 | 66.0 | 71.00 | 42.00 | 7.0/6.0 | 150.0/34090 | 10.22 |

FAQ: Frequently Asked Questions

Q: Is a stainless steel chain as strong as a carbon steel chain?

A: Generally, stainless steel chains have a lower tensile strength than high-carbon steel chains. However, in corrosive environments, a carbon steel chain loses its strength rapidly due to rust, whereas a stainless chain maintains its rated strength over a much longer lifecycle.

Q: Does a stainless steel chain need to be lubricated?

A: While stainless steel has better "dry-running" properties than carbon steel, we recommend using a food-grade H1 lubricant to minimize friction and wear. For applications where no lubricant is allowed, we offer specialized self-lubricating bushes.

Q: Which is better for a marine environment, 304 or 316?

A: Grade 316 is significantly better for marine or high-salinity environments. The molybdenum in 316 protects against "crevice corrosion" and salt-water pitting that will eventually damage 304.

Q: Can I use your stainless steel chain with standard iron sprockets?

A: You can, but it is not recommended for long-term use. To prevent "galvanic corrosion" and ensure the longest possible life for both components, we strongly recommend using stainless steel sprockets with your stainless chains.

Would you like me to help you draft a "Stainless Steel Grade Selection Guide" to assist your customers in choosing between 304 and 316 based on their specific chemical exposure?

English

Español

العربية

Français

Русский

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

አማርኛ

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Kiswahili

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

Հայերեն

עברית

Latine

Dansk

اردو

Shqip

বাংলা

Hrvatski

Afrikaans

Gaeilge

Eesti keel

Māori

සිංහල

नेपाली

Oʻzbekcha

latviešu

অসমীয়া

Aymara

Azərbaycan dili

Bamanankan

Euskara

Беларуская мова

भोजपुरी