Introduction to Plastic Chain Guides

Plastic chain guides are specialized engineering plastic components designed to support and guide chains in mechanical transmission systems. Featuring outstanding performance advantages, they are widely used across diverse industries.

Material Characteristics

Plastic chain guides are typically made from ultra-high molecular weight polyethylene (PE-UHM) and other high-performance engineering plastics. These materials integrate the strengths of various plastics, boasting exceptional wear resistance, impact toughness, self-lubrication, corrosion resistance, impact energy absorption, low-temperature resistance, hygienic safety, non-adhesion, and low water absorption.

Performance Advantages

-

Low Friction CoefficientThe inherent self-lubricating property of polyethylene reduces the friction coefficient to 1/5 of that between steel-on-steel contact. This allows for higher chain operating speeds with the same power input, lowers energy consumption, minimizes chain wear, and extends service life significantly.

-

Quiet OperationImpact noise between metal chains and steel guides often exceeds 85 decibels. In contrast, plastic chain guides utilize their elastic buffering capacity to dampen impact vibrations, reducing operational noise to below 60 decibels. This effectively prevents vibration interference with precision components in the system.

-

Superior Wear & Impact ResistanceIn oily environments like food processing workshops, plastic chain guides maintain a smooth, non-sticky surface and resist corrosion from acid-alkaline cleaning agents. In heavy-duty applications such as mining machinery conveying systems, their tough structure absorbs impact forces without deformation, denting, or cracking.

-

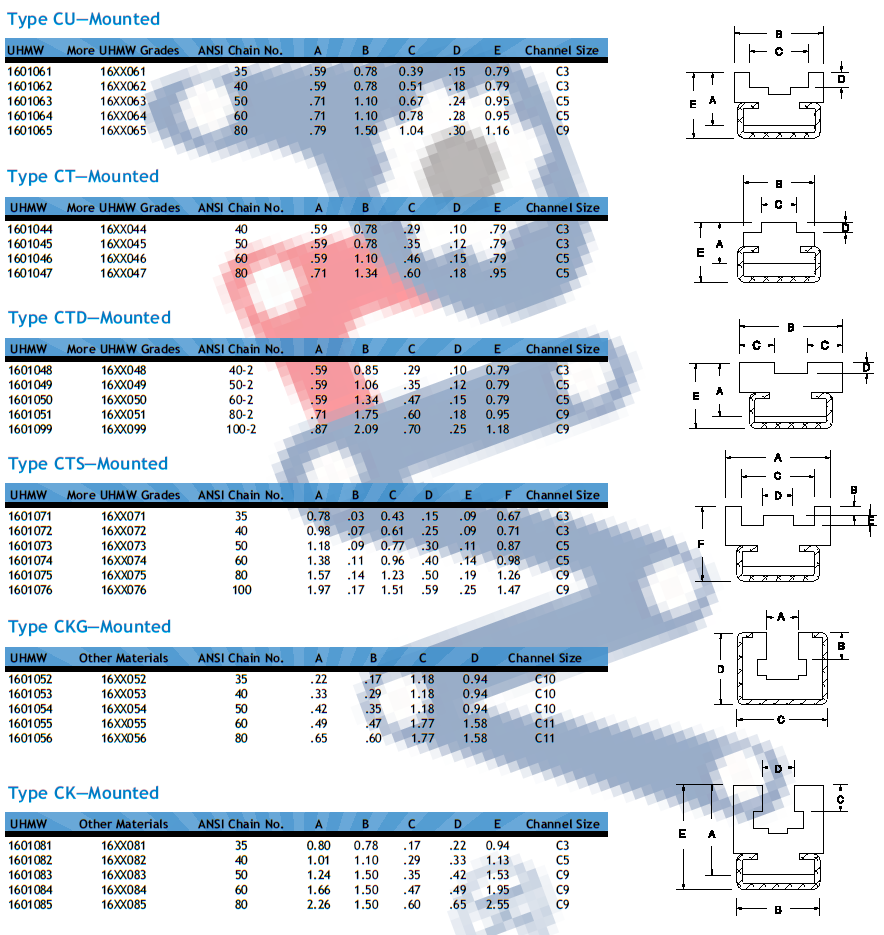

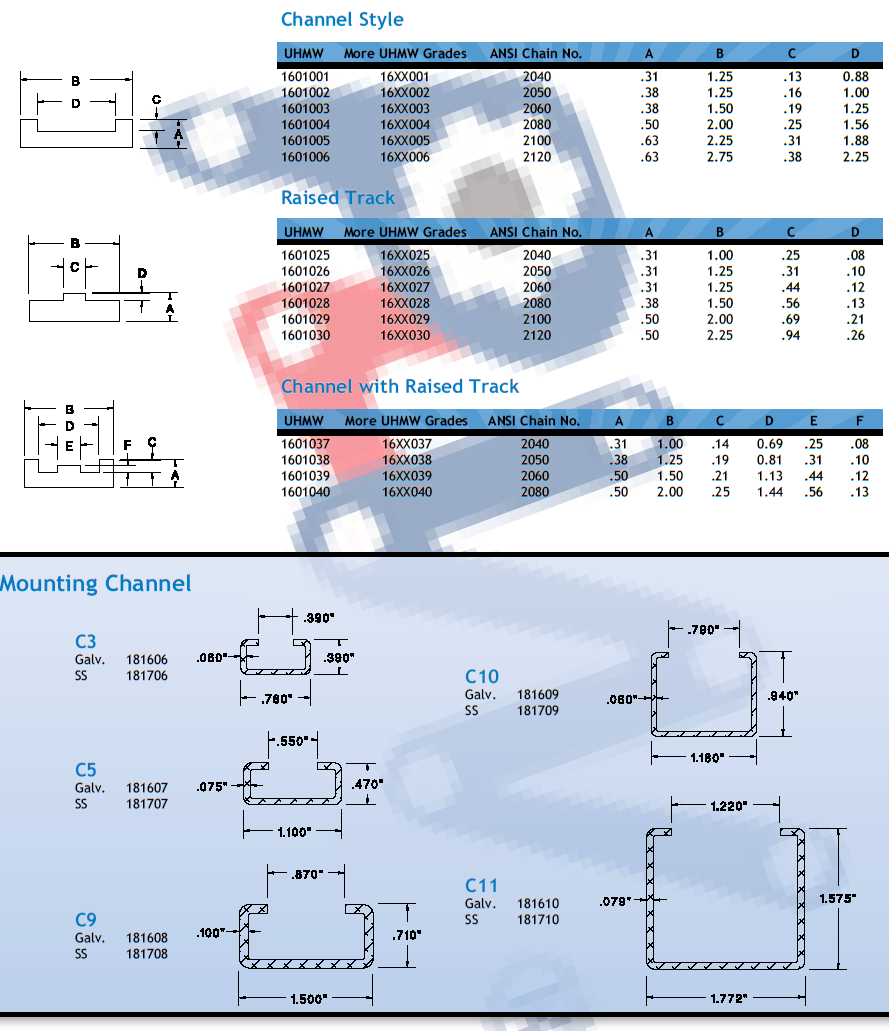

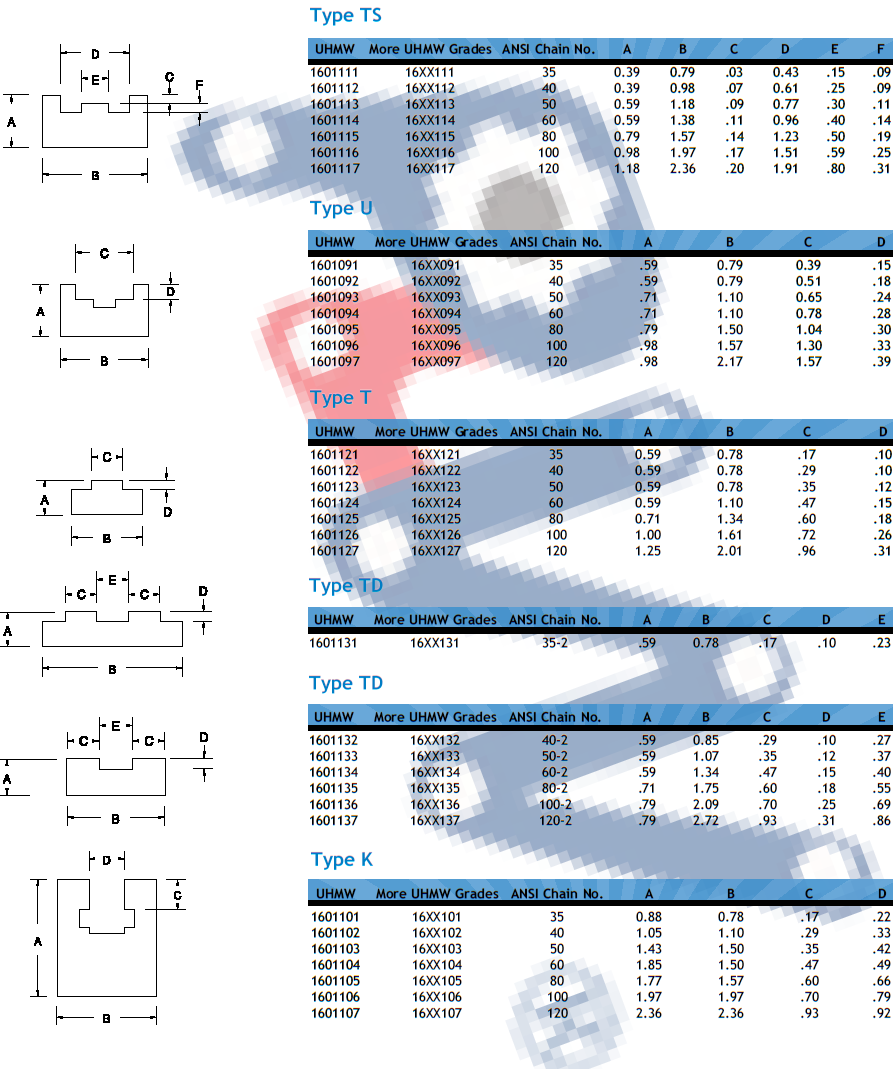

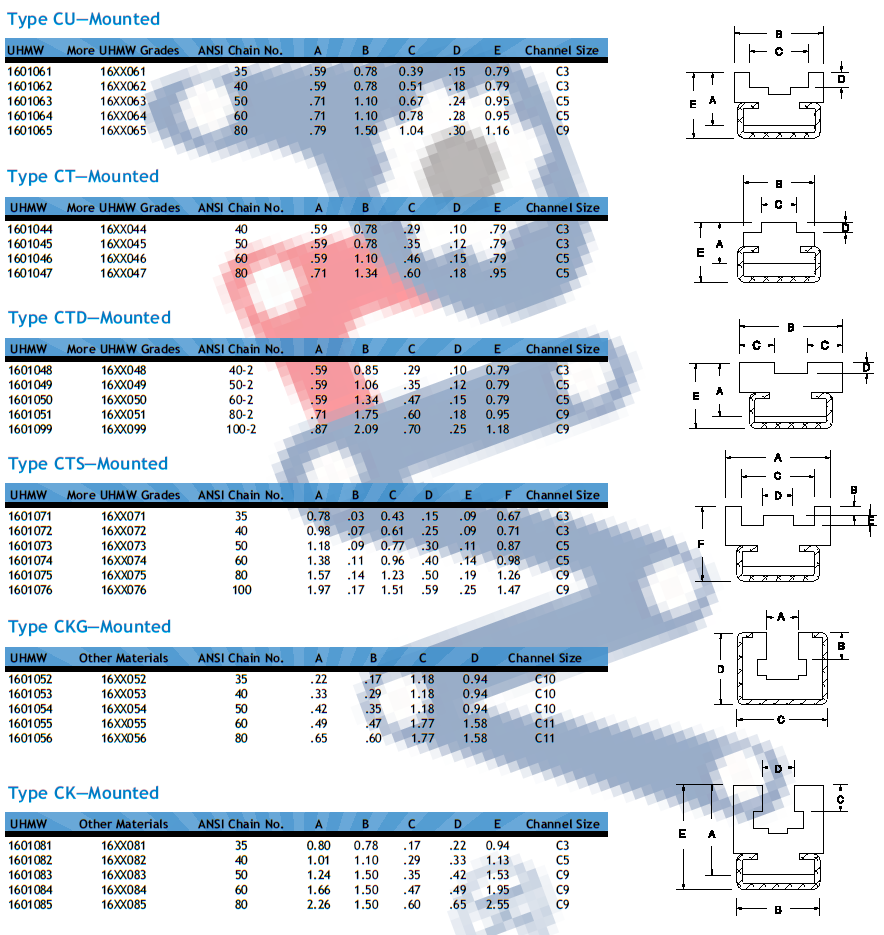

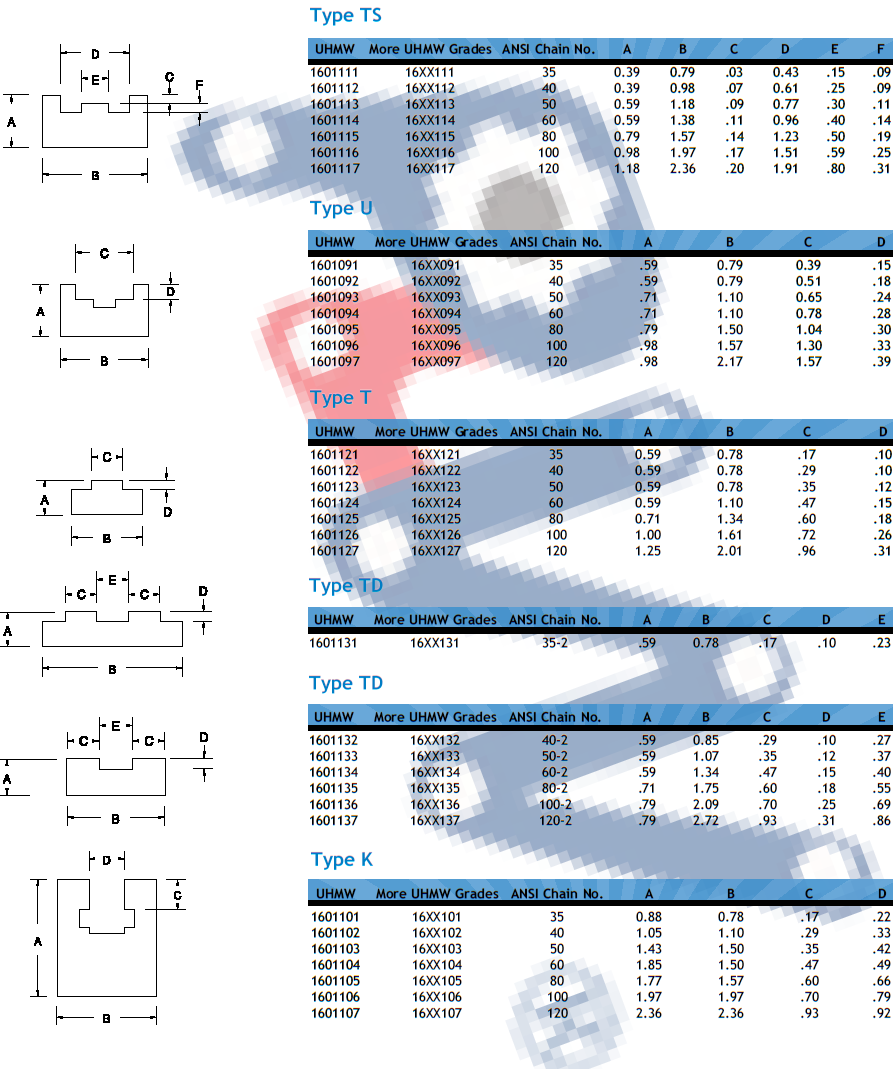

Customizable Design FlexibilityPlastic chain guides can be precision-machined to match specific chain models and movement paths. From linear tracks to curved bends, and from T-slotted profiles to stepped structures, they can be fully customized to integrate seamlessly into various production scenarios.

Application Fields

-

Food & Beverage IndustryIdeal for bottle/can filling lines, food packaging machines, and biscuit conveying systems. They meet food safety standards and can be used in direct contact with food products.

-

Logistics & Sortation SystemsApplied in parcel sorting machines and automated warehouse conveyor lines. Their customizable design enables seamless chain direction changes, improving sorting efficiency and system stability.

-

Wood & Paper IndustryUsed in wood conveying equipment and board production lines, withstanding continuous wear and impact during material handling processes.

-

Textile IndustryServes as guide rails for yarn and fabric conveying chains in textile machinery. Their low friction and quiet operation help enhance the quality of textile products.

-

Agricultural MachineryInstalled in conveying components of combine harvesters and seeders, adapting to harsh field working conditions such as dust, moisture, and variable temperatures.

-

Mining & Metallurgy IndustryAn excellent alternative to metal guides in heavy-duty conveyor systems, reducing equipment noise, wear rates, and overall maintenance costs.

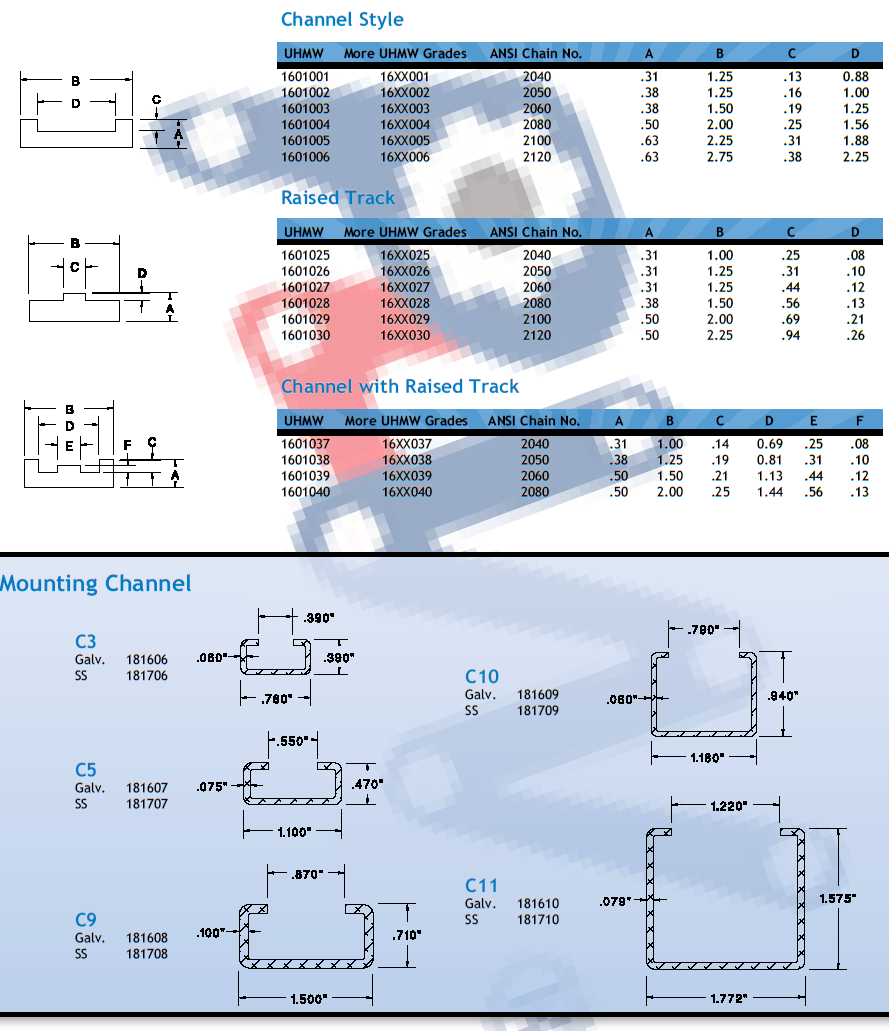

Appearance & Specifications

Plastic chain guides are generally elongated strips, with green being the most common color, and white or other colors also available. They come in a wide range of specifications; dimensions including shape, thickness, and width can be tailored to customer requirements. The maximum length of a single guide is usually 4000mm for most manufacturers, with some offering a maximum length of 3000mm.

English

Español

العربية

Français

Русский

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

አማርኛ

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Kiswahili

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

Հայերեն

עברית

Latine

Dansk

اردو

Shqip

বাংলা

Hrvatski

Afrikaans

Gaeilge

Eesti keel

Māori

සිංහල

नेपाली

Oʻzbekcha

latviešu

অসমীয়া

Aymara

Azərbaycan dili

Bamanankan

Euskara

Беларуская мова

भोजपुरी