Product Description

In the high-stakes environment of automated assembly and packaging, the conveyor chain is the backbone of your throughput. Our Double Pitch Conveyor Chain with Extended Pins is far more than a series of steel links; it is a meticulously crafted tool designed to eliminate the friction that slows your business down. Imagine an assembly line where every movement is whisper-quiet, where attachments click into place on perfectly aligned pins with a satisfying mechanical precision. That is the reality we build for you.

When you handle our chain, you will notice the cool, smooth finish of the induction-hardened steel, free from the oily residue or jagged edges often found in lower-tier products. This isn't mass-produced hardware; it is an engineering solution. The "extended pin" feature is our direct answer to the complex needs of modern logistics. Instead of relying on heavy, complex mounting brackets, these pins offer a minimalist, high-strength point of contact for your unique conveyor fixtures. By reducing the number of components in your system, we reduce the potential points of failure, giving you a streamlined, elegant, and incredibly robust transmission system that works as hard as you do.

Product Features and Highlights

Our double pitch chains are built to exceed the rigorous demands of industrial automation through several proprietary manufacturing advantages that define our E-E-A-T commitment:

Induction-Hardened Extended Pins: The pins are not just extended; they undergo localized induction hardening. This ensures that while the pin core remains tough and shock-resistant, the surface where your attachments rest is incredibly hard and resistant to "grooving" or abrasive wear.

Double-Pitch Efficiency: By doubling the pitch length relative to standard roller chains, we reduce the number of components per meter. This results in a lighter chain that requires less energy to drive, making it significantly more cost-effective for long-span conveyors.

Solid Roller Construction: Unlike inferior split-rollers that can deform or "unfurl" under pressure, our solid rollers distribute the load evenly across the sprocket teeth, reducing noise and extending the life of your entire drive system.

Pre-Stretched Assembly: We apply a rigorous pre-loading process to every chain before it leaves our facility. This removes the "initial elongation" often found in new installations, saving you from immediate and repetitive tension adjustments.

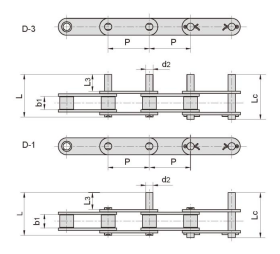

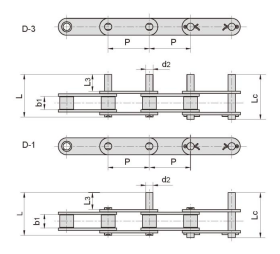

Customization & Pin Configuration Options

Every conveyor system is unique, and our extended pin series is designed with that flexibility in mind. We understand that a "standard" solution doesn't always solve a specific engineering problem on the factory floor.

Variable Pin Extensions: We can manufacture pins that extend from one side, both sides, or in staggered patterns (e.g., every 2nd or 4th link) to match your machine's indexing needs.

Multiple End-Styles: Choose from flat-ended, chamfered, or grooved pins. Grooved pins allow for the easy installation of snap-rings or circlips to secure your attachments safely.

Material Diversification: For caustic wash-down environments in food processing or chemical plants, we offer nickel-plated, zinc-plated, or full 304/316 stainless steel options.

Large vs. Standard Rollers: Depending on whether your chain rolls on a metal track (Large Roller) or slides on a wear-strip (Standard Roller), we provide optimized roller diameters to minimize friction and heat.

Material Integrity & Manufacturing Excellence

Quality starts with metallurgy. Our chains are forged from premium-grade 40Mn and 45Mn carbon steel, chosen for their superior response to heat treatment. Our manufacturing process follows a strict protocol:

Precision Grinding: The extended pins undergo centerless grinding to achieve a diameter tolerance within microns. This ensures that your attachments fit perfectly every time, preventing "wobble" that can lead to system fatigue.

Atmospheric Controlled Heat Treatment: Our link plates and pins are treated in a carbonitriding furnace. This creates a hard, wear-resistant "skin" while maintaining a ductile core that can absorb sudden shocks without snapping.

Advanced Shot-Peening: Each link plate is shot-peened to induce compressive surface stresses. This acts as a shield against fatigue cracks, especially in high-cycle conveyor applications where the chain is constantly under tension.

Automated Lubrication Dipping: We don't just spray the chain; we submerge it in a proprietary hot-oil bath. This ensures the lubricant penetrates the critical bearing area between the pin and bushing, protecting the chain from its first rotation.

Application Insights & Industry Use-Cases

The Double Pitch Conveyor Chain with Extended Pins is a versatile workhorse found in almost every sector of modern production. Its ability to carry payloads via the pins makes it indispensable for several high-demand scenarios:

Automotive Component Transport: Carrying sensitive engine parts or chassis components through assembly stations using custom-molded pin fixtures.

Food Processing & Drying: Utilizing stainless steel extended pins to hold mesh screens or trays in large-scale industrial ovens and dryers where hygiene is paramount.

Packaging & Labeling: Providing the precision timing and attachment points needed for high-speed bottle or carton indexing and spacing.

Electronics Manufacturing: Handling delicate PCBs through soldering and testing phases where precise positioning on the pins is critical for robotic accuracy.

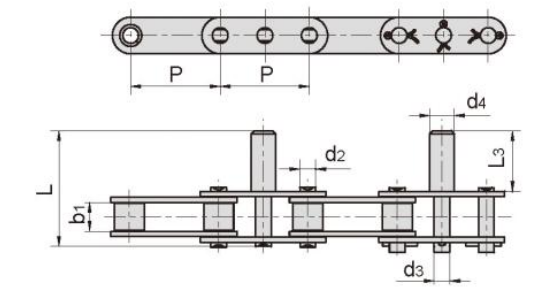

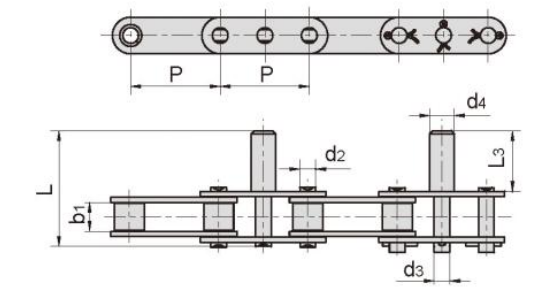

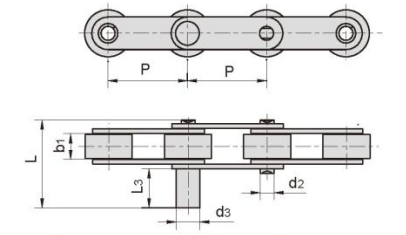

Technical Specifications & Parameter Table

DIN/ISO

Chain

No. | ANSI

Chain

No. | P | b1 | d2 | L3 | L | Lc |

DIN/ISO

Cadena No | ANSI

Cadena No | mm | mm | mm | mm | mm | mm |

C208A

C208AL | C2040

C2042 | 25.40 | 7.85 | 3.96 | 9.5 | 25.1 | 26.2 |

C210A

C220AL | C2050

C2052 | 31.75 | 9.40 | 5.08 | 11.9 | 31.3 | 33.1 |

C212A

C212AL | C2060

C2062 | 38.10 | 12.57 | 5.94 | 14.3 | 38.6 | 40.6 |

C212AH

C212AHL | C2060H

C2062H | 38.10 | 12.57 | 5.94 | 14.3 | 42.0 | 43.8 |

C216A

C216AL | C2080

C2082 | 50.80 | 15.75 | 7.92 | 19.1 | 50.3 | 53.3 |

C216AH

C216AHL | C2080H

C2082H | 50.80 | 15.75 | 7.92 | 19.1 | 53.5 | 55.0 |

C220A

C220AL | C2100

C2102 | 63.50 | 18.90 | 9.53 | 23.8 | 61.8 | 66.1 |

C220AH

C220AHL | C2100H

C2102H | 63.50 | 18.90 | 9.53 | 23.8 | 65.0 | 68.3 |

C224AH

C224AHL | C2120H

C2122H | 76.20 | 25.22 | 11.10 | 28.6 | 79.6 | 83.6 |

C232AH

C232AHL | C2160H

C2162H | 101.60 | 31.75 | 14.27 | 38.1 | 103.0 | 107.8 |

| CHAIN NO. | P | b1 | d2 | d3 | d4 | L3 | L |

| Cadena No | mm | mm | mm | mm | mm | mm | mm |

| C2052F2 | 31.75 | 9.40 | 5.08 | 6.00 | 7.0 | 20.0 | 39.8 |

| C2052F14 | 31.75 | 9.40 | 5.08 | 6.00 | 7.0 | 21.0 | 40.4 |

| C2062-D38 | 38.10 | 12.57 | 5.94 | 5.94 | 11.1 | 24.2 | 48.6 |

| C2062-D39 | 38.10 | 12.57 | 5.94 | 5.94 | 13.3 | 32.2 | 56.6 |

| C212AHL-D4 | 38.10 | 12.57 | 5.94 | 5.94 | 8.0 | 25.0 | 53.0 |

| C212AHF3 | 38.10 | 12.57 | 5.94 | 8.08 | 10.0 | 35.0 | 63.0 |

| C212AHF7 | 38.10 | 12.57 | 5.94 | 5.94 | 12.7 | 41.2 | 69.2 |

| C212AHF8 | 38.10 | 12.57 | 5.94 | 8.00 | 10.0 | 35.0 | 63.0 |

| C2060HF9 | 38.10 | 12.57 | 5.94 | 7.95 | 12.7 | 41.3 | 69.3 |

| C2060HF10 | 38.10 | 12.57 | 5.94 | 7.70 | 14.3 | 41.3 | 69.3 |

| C2060H-D23 | 38.10 | 12.57 | 5.94 | 8.80 | 12.7 | 41.3 | 69.3 |

| C2060H-D24 | 38.10 | 12.57 | 5.94 | 7.95 | 12.7 | 44.8 | 65.6 |

| C2060H-D31 | 38.10 | 12.57 | 5.94 | 7.95 | 16.0 | 45.0 | 73.0 |

| C2062H-D41 | 38.10 | 12.57 | 5.94 | 9.53 | 9.5 | 22.2 | 50.0 |

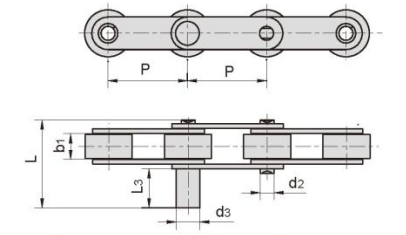

| CHAIN NO. | P | b1 | d2 | d3 | L3 | L |

| Cadena No | mm | mm | mm | mm | mm | mm |

| C2052DF1 | 31.75 | 9.40 | 5.08 | 7.50 | 14.15 | 33.6 |

| C210AF4 | 31.75 | 9.40 | 5.08 | 11.00 | 34.00 | 53.7 |

| C2052-D4 | 31.75 | 9.40 | 5.08 | 6.00 | 32.40 | 52.0 |

| C2050-D5 | 31.75 | 9.40 | 5.08 | 8.00 | 40.00 | 59.7 |

| C212AHL-D4 | 38.10 | 12.57 | 5.94 | 8.00 | 25.00 | 53.0 |

| C2062-D6 | 38.10 | 12.57 | 5.94 | 12.00 | 25.00 | 49.7 |

FAQ: Frequently Asked Questions

Q: Can I get custom pin lengths that aren't listed in your standard catalog?

A: Absolutely. Most of our extended pin orders are custom-to-print. You can specify the exact extension length required for your attachments, and we will manufacture them to your precise tolerance.

Q: Is it better to use Large Rollers or Standard Rollers for my conveyor?

A: If the chain is intended to roll along a rail or support-structure, Large Rollers (e.g., C2062) are superior as they reduce rolling friction. If the chain is simply pulling a load and the rollers aren't in contact with a track, Standard Rollers (e.g., C2060) are a lighter choice.

Q: How do I secure my attachments to the extended pins?

A: We offer pins with snap-ring grooves or cross-drilled holes for cotter pins. Alternatively, many customers use a press-fit or a simple set-screw fixture depending on the load and speed of the conveyor.

Q: How does the "Double Pitch" design affect the strength compared to a standard roller chain?

A: The tensile strength remains virtually identical to the standard pitch version because the pins and link-plate thicknesses are the same. However, because there are fewer joints per meter, it is often more reliable in long-distance conveyor applications.

Would you like me to generate a specific technical guide on how to calculate the maximum allowable load for your custom pin attachments?

English

Español

العربية

Français

Русский

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

አማርኛ

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Kiswahili

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

Հայերեն

עברית

Latine

Dansk

اردو

Shqip

বাংলা

Hrvatski

Afrikaans

Gaeilge

Eesti keel

Māori

සිංහල

नेपाली

Oʻzbekcha

latviešu

অসমীয়া

Aymara

Azərbaycan dili

Bamanankan

Euskara

Беларуская мова

भोजपुरी