Chinese High Quality Surface Blackening Treatment Sprocket

Blackened sprockets (sprocket surfaces treated with blackening processes) are widely used in mechanical transmission due to their unique surface treatment properties and performance advantages. Below is a detailed analysis of their core benefits:

1. Enhanced Corrosion Resistance to Delay Rust

The core of blackening treatment is forming a dense ferric oxide (Fe₃O₄) film on the sprocket surface through chemical reactions. This film effectively isolates the sprocket substrate from air, moisture, and some corrosive media, significantly slowing down metal rusting:

In dry or mildly humid environments, the blackened layer can protect the sprocket from rust for extended periods, reducing transmission jamming or precision degradation caused by corrosion.

When combined with subsequent oil immersion, the oil film penetrates the micropores of the oxide layer, further enhancing sealing and corrosion resistance to extend the sprocket’s service life.

2. Improved Surface Hardness and Wear Resistance

The hardness of the blackened oxide film (typically 200-300HV) is higher than that of the sprocket substrate (e.g., 45# steel substrate hardness is approximately 180HV), reducing surface wear during meshing between the sprocket and chain:

Minimizes friction loss between the sprocket teeth and chain rollers/links, reducing metal debris generated during transmission.

The dense oxide film adheres firmly to the substrate and is not easily peeled off, maintaining wear resistance over time and extending the overall lifespan of both the sprocket and chain.

3. No Impact on Dimensional Accuracy, Ensuring Transmission Stability

The blackened film is extremely thin (usually only 0.5-1.5 microns), barely altering the sprocket’s original dimensions, tolerances, or tooth profile accuracy:

For high-precision transmission systems (e.g., machine tools, precision conveyors), blackening does not affect the meshing clearance or transmission accuracy between the sprocket and chain, avoiding assembly issues caused by surface treatment.

Suitable for dimension-sensitive scenarios, allowing direct assembly without additional size corrections.

4. Low Cost and Simple, Scalable Process

Compared to surface treatments like electroplating, chrome plating, or spraying, blackening offers significant cost advantages:

Requires minimal equipment investment, has a short process flow (pre-treatment → blackening reaction → post-treatment), and low per-unit processing cost, making it ideal for mass production.

Avoids complex environmental treatment (e.g., wastewater handling in electroplating), making it more accessible for small and medium enterprises or low-cost demand scenarios, providing excellent value for money in surface protection.

5. Improved Surface Lubricity to Reduce Transmission Loss

The microporous structure of the blackened layer can adsorb small amounts of lubricants (e.g., machine oil), forming an oil film during transmission that reduces the friction coefficient between the sprocket and chain:

Lowers frictional resistance and power loss during transmission, improving efficiency.

Reduces meshing noise and enhances transmission smoothness.

6. Uniform Appearance for Versatile Applications

Blackened sprockets have a uniform blue-black or brown surface with a consistent industrial aesthetic:

Can be used directly as the final surface for non-highly decorative scenarios.

The surface is compatible with secondary treatments like painting or coating to further enhance protection or modify appearance (e.g., for color-coding needs).

7. Wide Material Compatibility

Blackening adapts well to common sprocket materials (e.g., 45# steel, 20# steel, 40Cr alloy structural steel), improving their performance:

Summary

The core advantages of blackened sprockets lie in their low-cost, cost-effective protective performance, while also offering wear resistance, dimensional stability, and process simplicity. They are particularly suitable for general mechanical transmission scenarios in dry or mildly humid environments (e.g., machine tools, conveyors, agricultural machinery). Although their corrosion resistance is weaker than electroplated or stainless steel alternatives, blackening remains an ideal choice for balancing performance, cost, and precision in non-extreme corrosive environments.

03-085sprocket.pdf

03-085sprocket.pdf

Chain Wheel Catalog.pdf

Chain Wheel Catalog.pdf

Application

High temperature environment, corrosive environment

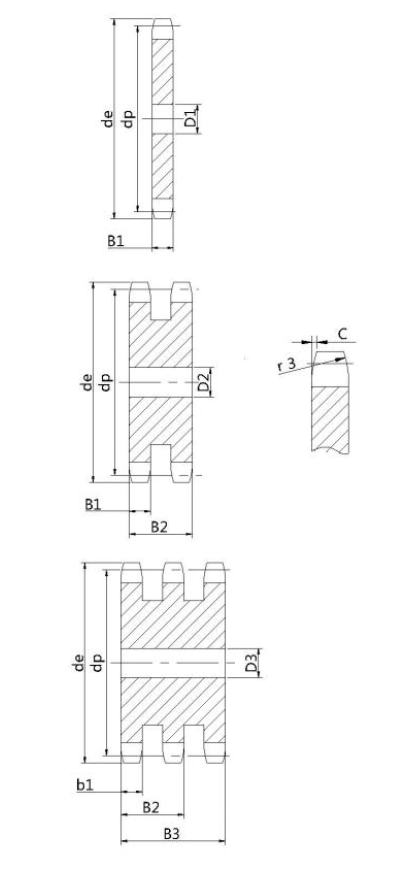

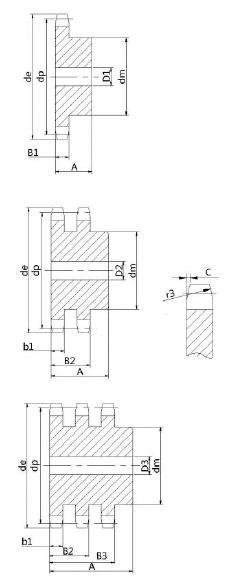

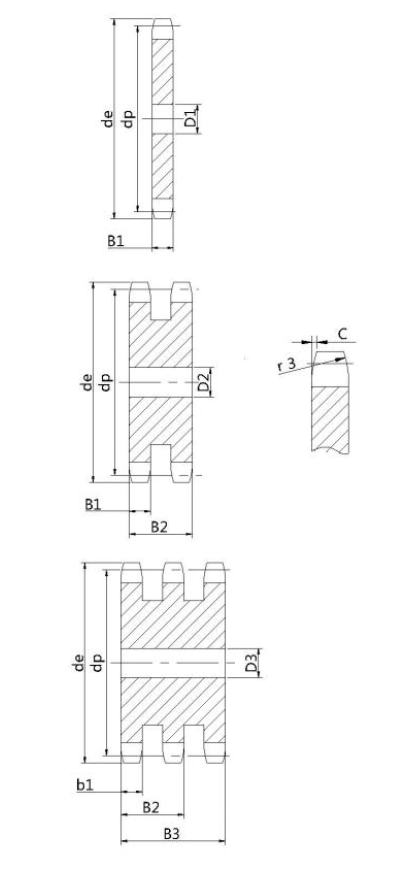

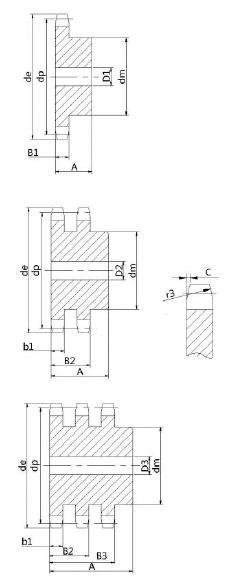

| Type | P | Roller | B1 | b1 | B2-b1 | Intermal width |

| 04C | 6.35 | 3.3 | 2.7 | 2.5 | 6.4 | 3.18 |

| 04B | 6 | 4 | 2.3 | | | 2.8 |

| 05B | 8 | 5 | 2.6 | 2.4 | 5.64 | 3 |

| 06C | 9.525 | 5.08 | 4.2 | 4 | 10.13 | 4.77 |

| 06B | 9.525 | 6.35 | 5.2 | 5 | 10.24 | 5.72 |

| 08A | 12.7 | 7.95 | 7.2 | 6.9 | 14.38 | 7.85 |

| 08B | 12.7 | 8.51 | 7.1 | 6.8 | 13.92 | 7.75 |

| 10A | 15.875 | 10.16 | 8.7 | 8.4 | 18.11 | 9.4 |

| 10B | 15.875 | 10.16 | 8.9 | 8.6 | 16.59 | 9.65 |

| 12A | 19.05 | 11.91 | 11.7 | 11.3 | 22.78 | 12.57 |

| 12B | 19.05 | 12.07 | 10.8 | 10.5 | 19.46 | 11.68 |

| 16A | 25.4 | 15.88 | 14.6 | 14.1 | 29.29 | 15.75 |

| 16B | 25.4 | 15.88 | 15.9 | 15.4 | 31.88 | 17.02 |

| 20A | 31.75 | 19.05 | 17.6 | 17 | 35.76 | 18.9 |

| 20B | 31.75 | 19.05 | 18.3 | 17.7 | 36.45 | 19.56 |

| 24A | 38.1 | 22.23 | 23.5 | 22.7 | 45.44 | 25.22 |

| 24B | 38.1 | 25.4 | 23.7 | 22.9 | 48.36 | 25.4 |

| 28A | 44.45 | 25.4 | 24.5 | 22.7 | 48.87 | 25.22 |

| 28B | 44.45 | 27.94 | 30.3 | 28.5 | 59.56 | 30.99 |

| 32A | 50.8 | 28.58 | 29.4 | 28.4 | 58.55 | 31.55 |

| 32B | 50.8 | 29.21 | 28.9 | 27.9 | 58.55 | 30.99 |

English

Español

العربية

Français

Русский

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

አማርኛ

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Kiswahili

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

Հայերեն

עברית

Latine

Dansk

اردو

Shqip

বাংলা

Hrvatski

Afrikaans

Gaeilge

Eesti keel

Māori

සිංහල

नेपाली

Oʻzbekcha

latviešu

অসমীয়া

Aymara

Azərbaycan dili

Bamanankan

Euskara

Беларуская мова

भोजपुरी