Product Description

In the fast-paced world of industrial manufacturing, the ability to pivot and adapt is the difference between leading the market and falling behind. Our High Precision Hollow Pin Chain is the engineer's "Swiss Army Knife" for power transmission. Imagine a conveyor system where you can reposition your carrying attachments in seconds rather than hours. This chain offers a tactile experience of pure industrial quality—its surface is a smooth, satin-finished steel, cold to the touch and reflecting the light of a well-ordered factory floor. When in motion, it operates with a rhythmic, quiet precision that signifies a perfectly balanced mechanical system.

Gone are the days of struggling with heavy, fixed-link chains that limit your creative solutions. Whether you are running a delicate electronics assembly line or a high-heat baking oven, our hollow pin chain feels like a natural extension of your machinery. It provides the freedom to design custom tray carriers or spacer bars that slide effortlessly into the hollow pins, held in place by the sheer accuracy of our manufacturing. By choosing this chain, you aren't just buying a component; you are investing in the agility of your entire production process, ensuring your facility remains whisper-quiet, incredibly efficient, and ready for any custom order that comes your way.

Product Features and Highlights

Our hollow pin chains are defined by four engineering pillars that ensure they outperform standard alternatives in high-precision environments:

Integrated Attachment Versatility: The hollow center of the pin is the star feature. It acts as a universal mounting point, allowing for the quick installation of cross-rods or side attachments. This eliminates the need for specialized "attachment links" (like A1 or K1), significantly reducing the cost and complexity of your conveyor design.

High-Tolerance Internal Geometry: We utilize advanced centerless grinding for the pins and precision-honed bores for the bushings. This ensures that the hollow pin maintains its structural integrity even under high tensile loads, preventing the "flattening" or distortion common in low-quality hollow chains.

Dynamic Load Balancing: Despite the hollow design, our chains are heat-treated using a specific carbonitriding process that gives the pins a hard, wear-resistant outer shell and a ductile core. This allows the chain to absorb the shock loads of frequent starts and stops without cracking.

Reduced System Weight: The hollow pin design naturally reduces the overall mass of the chain. For long conveyor runs, this weight saving translates directly into reduced motor strain and lower electricity costs, making your operation more sustainable and profitable.

Manufacturing Precision & Material Excellence

The "High Precision" in our product name is backed by a rigorous manufacturing protocol that prioritizes E-E-A-T (Experience, Expertise, Authoritativeness, and Trustworthiness). We understand that in a hollow pin chain, every millimeter of tolerance matters.

Certified Raw Materials: We source premium 40Mn carbon steel and 304/316L stainless steel. Every batch is tested for chemical purity and grain structure to ensure it meets our "Zero-Failure" mandate before production begins.

Cold-Drawn Seamless Technology: Our hollow pins are created using a cold-drawing process that ensures a perfectly smooth internal bore. This is critical because any internal burrs or irregularities can prevent the smooth insertion of cross-rods or cause premature pin failure.

Advanced Shot-Peening: All link plates undergo high-velocity shot-peening to introduce compressive surface stresses. This significantly enhances the fatigue life of the chain, ensuring it can withstand millions of cycles without stress fractures.

Isothermal Heat Treatment: We use a controlled-atmosphere furnace to ensure uniform hardness. This prevents the "brittleness" often found in chains that are rapidly quenched, resulting in a product that is both hard enough to resist wear and tough enough to resist snapping.

Attachment Integration & Cross-Rod Applications

The true value of a hollow pin chain is found in how it interacts with the rest of your system. It is designed to be the "skeleton" onto which you build your custom application.

Cross-Rod Conveyors: Perfect for bakery ovens or drying tunnels where mesh belts or trays are supported by rods passing through the chain links.

Spacer Bar Indexing: Ideal for packaging lines where items must be kept at a fixed distance; simply slide a spacer rod through the hollow pin to maintain perfect alignment.

Fixture Mounting: Use the pins as a base for custom-molded jigs or specialized electronic component carriers that require precise orientation.

Ease of Repair: Because attachments aren't riveted, you can replace a single cross-rod or fixture in minutes without needing to break the master link of the chain.

Maintenance & Operational Longevity

A precision instrument requires professional care. To ensure your hollow pin chain lasts for years of continuous service, we recommend the following maintenance protocols:

Initial Lubrication Penetration: Our chains are pre-lubricated with a high-tack industrial oil. For food-grade applications, we offer a specialized H1-certified dry-film lubricant that prevents flour or dust from clogging the hollow pins.

Alignment Accuracy: Ensure that your sprockets are aligned within a 0.5-degree tolerance. Hollow pin chains are particularly sensitive to "twisting" forces if the sprockets are misaligned.

Elongation Monitoring: Regularly check for chain "stretch." Once the chain reaches 2.0% elongation, it should be replaced to prevent damage to the sprocket teeth and to maintain the precision of your attachment indexing.

Cleaning the Bores: If operating in a dirty environment, periodically blow out the hollow pin centers with compressed air to prevent debris buildup that could seize your cross-rods.

Why Choose Us?

Partnering with us means gaining access to a legacy of engineering excellence. We don't just supply chains; we provide the mechanical foundation for your success.

Engineering Consulting: Not sure if a hollow pin chain can handle your specific payload? Our technical team can perform a "Load-Life Calculation" for you, ensuring you pick the right size for your cycle requirements.

Customization Without Borders: We can provide custom internal diameters ($d_1$) for the hollow pins if your existing cross-rods require a non-standard fit.

Proven Track Record: Our chains are currently powering high-speed assembly lines in the automotive, pharmaceutical, and food-processing industries globally.

Rapid Response Inventory: We maintain a vast stock of standard 08BHP to 16BHP and 40HP to 80HP sizes, allowing for immediate shipping to minimize your downtime during maintenance cycles.

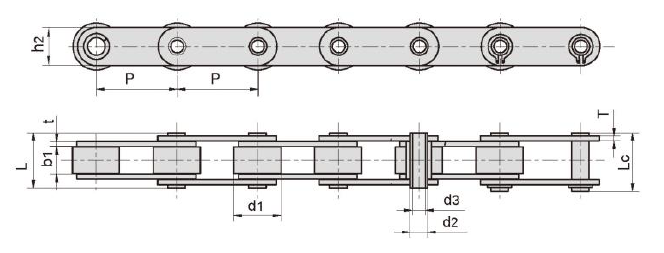

Technical Specifications & Parameter Table

CHAIN NO. | Pitch | Bush

diameter | Width

belween

inner plates | Pin

diameter | Pin length | Inner

Plate

depth | Plate

thickness | Ulimate

tensile

strength | Avcrage

tensilo

strength | Weight

Del

meter |

Cadena No. | Paso | Diametro

casquillo | Ancho

interior | Diametro

pasador | Longitud

pasador | Altura

placas | Ancho

placas | Resis.

rotura | Resis.

media

traccion | Peso

por

metro |

P | d

max | bt

min | d

max | d

min | L

max | Lc

max | h2

max | t/T

max | Q

min | Q。 | q |

mm | mm | mm | mm | mm | mm | mm | mm | mm | kN/LB | KN | kg/m |

08BHPF | 12.700 | 8.51 | 7.75 | 6.55 | 4.50 | 16.4 | 17.6 | 11.80 | 1.6/1.3 | 11.1/2523 | 12.1 | 0.56 |

08BHPF5 | 12.700 | 8.51 | 7.75 | 6.30 | 4.50 | 16.8 | 18.0 | 12.00 | 1.60 | 9.6/2182 | 10.6 | 0.62 |

10BHPF3 | 15.875 | 10.16 | 9.65 | 7.02 | 5.13 | 19.5 | 20.5 | 14.70 | 1.70 | 10.0/2272 | 11.5 | 0.86 |

10BHPF4 | 15.875 | 10.16 | 9.50 | 7.20 | 5.00 | 19.8 | 213 | 14.00 | 2.03/1.6 | 12.5/2840 | 14.0 | 0.82 |

12BHPF2 | 19.050 | 12.07 | 11.68 | 8.09 | 6.00 | 227 | 23.9 | 16.10 | 1.85 | 14.0/3180 | 16.0 | 0.82 |

12BHPF3 | 19.050 | 12.07 | 11.70 | 8.22 | 5.75 | 23.6 | 24.9 | 16.20 | 2.42/1.85 | 16.0/3636 | 18.0 | 1.14 |

16BHPF3 | 25.400 | 15.88 | 17.02 | 11.50 | 8.20 | 35.3 | 37.0 | 23.20 | 4.0/3.1 | 49.0/11136 | 25.2 | 2.26 |

16BHPF4 | 25.400 | 11.70 | 13.50 | 8.00 | 4.30 | 28.9 | 30.2 | 21.30 | 3.00 | 30.0/6818 | 33.0 | 1.81 |

40HP | 12.700 | 7.95 | 7.85 | 5.63 | 4.00 | 16.5 | 17.6 | 12.00 | 1.50 | 11.0/2500 | 12.2 | 0.54 |

08BHPF7 | 12.700 | 8.51 | 9.20 | 6.55 | 4.10 | 17.8 | 19.0 | 11.80 | 1.60 | 11.1/2523 | 12.1 | 0.64 |

08BHP | 12.700 | 8.51 | 7.75 | 6.55 | 4.50 | 16.4 | 17.6 | 11.80 | 1.30 | 11.1/2523 | 12.1 | 0.52 |

50HP | 15.875 | 10.16 | 9.40 | 7.03 | 5.13 | 20.7 | 219 | 15.09 | 2.03 | 20.0/4545 | 22.6 | 0.91 |

50HPF4 | 15.875 | 10.16 | 8.80 | 7.03 | 5.13 | 19.9 | 211 | 15.09 | 2.03 | 18.0/4180 | 19.2 | 0.89 |

50HP-HP | 15.875 | 10.16 | 9.40 | 7.03 | 5.13 | 22.6 | 23.7 | 15.09 | 2.42 | 20.0/4545 | 22.6 | 1.02 |

60HP | 19.050 | 11.91 | 12.70 | 8.31 | 6.00 | 25.8 | 26.8 | 18.00 | 2.42 | 24.0/5455 | 26.9 | 1.29 |

60HPF1 | 19.050 | 11.91 | 12.70 | 8.31 | 5.01 | 25.5 | 26.8 | 18.00 | 2.42 | 28.0/6364 | 30.9 | 1.37 |

80HP | 25.400 | 15.88 | 15.75 | 11.40 | 8.05 | 32.5 | 33.8 | 24.00 | 3.25 | 50.0/11364 | 52.0 | 2.26 |

80HPF1 | 25.400 | 11.70 | 13.50 | 7.80 | 4.00 | 27.0 | 28.4 | 21.50 | 2.42 | 27.44/6236 | 29.3 | 1.50 |

80HPF2 | 25.400 | 15.88 | 15.75 | 11.40 | 8.40 | 32.5 | 33.8 | 24.00 | 3.25 | 45.0/10227 | 48.0 | 2.23 |

80H-HP | 25.400 | 15.88 | 15.75 | 11.40 | 8.05 | 35.7 | 37.0 | 24.00 | 4.00 | 50.0/11364 | 52.0 | 2.63 |

80HPF3 | 25.400 | 15.88 | 15.88 | 11.40 | 7.96 | 324 | 33.8 | 23.24 | 3.25 | 50.0/11364 | 52.0 | 2.26 |

80HPF4 | 25.400 | 11.70 | 13.50 | 7.80 | 4.10 | 29.0 | 30.5 | 21.50 | 3.00 | 40.9/9091 | 43.2 | 1.77 |

HB41.75F5 | 41.750 | 17.11 | 19.90 | 14.11 | 10.30 | 39.0 | 40.4 | 25.26 | 4.00 | 49.0/11136 | 53.9 | 2.11 |

A2080HP | 50.800 | 15.83 | 15.75 | 11.40 | 8.05 | 32.4 | 33.8 | 24.00 | 3.25 | 42.3/9615 | 46.1 | 1.60 |

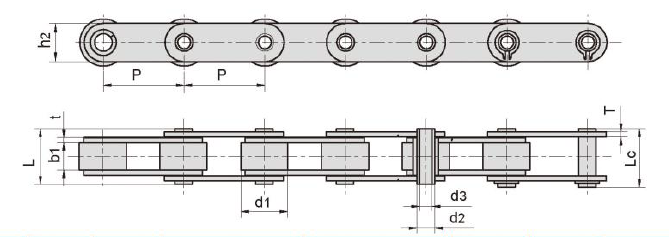

CHAN NO. | Pitch | Bush

diameto | Width

between

inner plates | Pin

diameter | Pin length | Inne

Plate

depth | Plate

thickness | Ullimate

tensile

strength | Average

tensile

strength | Weight

per

meter |

Cadena No | Paso | Diámetro

casquillo | Ancho

interior | Diámetro

pasador | Longitud

pasador | Altura

placas | Ancho

placas | Resis.

rotura | Resis.

media

tracción | Peso

por

metrO |

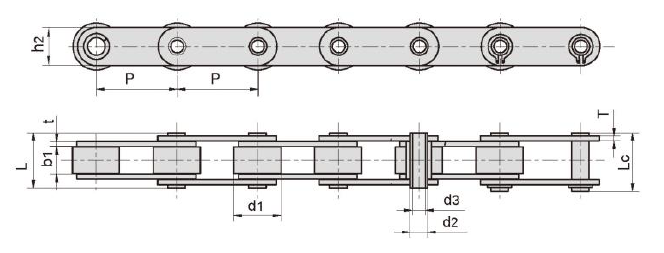

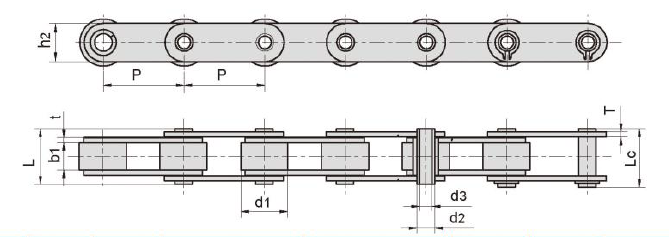

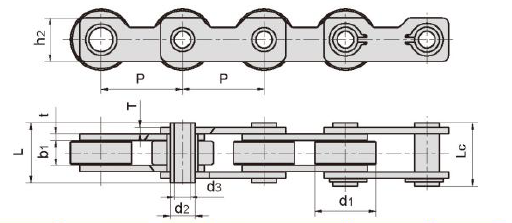

P | d1

max | b1

min | d2

max | d3

min | L

max | Lc

max | h2

max | T

max | Q

min | 8 | q |

mm | mm | mm | mm | mm | mm | mm | mm | mm | KN/LB | KN | kg/m |

C2040HP | 25.400 | 7.95 | 7.85 | 5.63 | 4.00 | 16.5 | 17.6 | 12.00 | 1.50 | 11.0/2500 | 12.6 | 0.46 |

C2040HPF1 | 25.400 | 7.95 | 7.85 | 5.63 | M4 | 16.5 | 17.6 | 12.00 | 1.50 | 9.0/2045 | 9.9 | 0.44 |

C2050HP | 31.750 | 10.16 | 9.40 | 7.22 | 5.12 | 20.5 | 21.8 | 15.00 | 2.03 | 20.4/4636 | 22.8 | 0.76 |

C2060HP | 38.100 | 11.91 | 12.70 | 8.31 | 6.00 | 25.8 | 26.8 | 17.00 | 2.42 | 24.0/5455 | 27.1 | 1.02 |

HP40F1 | 40.000 | 18.00 | 22.00 | 12.00 | 8.00 | 47.5 | 48.2 | 35.00 | 5.00 | 57.0/13049 | 63.8 | 5.38 |

HP40F2 | 40.000 | 18.00 | 22.00 | 12.00 | 8.20 | 47.5 | 48.2 | 35.00 | 5.00 | 57.0/13049 | 63.0 | 5.37 |

C2080HP | 50.800 | 15.88 | 15.75 | 11.40 | 8.05 | 32.5 | 33.8 | 24.00 | 3.25 | 50.0/11364 | 52.0 | 1.81 |

HP50F1 | 50.000 | 26.00 | 14.50 | 20.00 | 14.70 | 35.3 | 36.2 | 40.00 | 3.10 | 30.0/6818 | 33.6 | 3.98 |

C40HP | 12.700 | 7.95 | 7.85 | 5.63 | 4.00 | 16.5 | 17.6 | 12.00 | 1.50 | 110/2500 | 12.2 | 0.64 |

C50HP | 15.875 | 10.16 | 9.40 | 7.03 | 5.13 | 20.7 | 21.9 | 15.09 | 2.03 | 20.0/4545 | 22.6 | 1.05 |

C60HP | 19.050 | 11.91 | 12.70 | 8.31 | 6.00 | 25.8 | 26.8 | 18.00 | 2.42 | 24.0/5455 | 26.9 | 1.52 |

C80HP | 25.400 | 15.88 | 15.75 | 11.40 | 8.05 | 32.5 | 33.8 | 24.00 | 3.25 | 50.0/11364 | 52.0 | 263 |

C08EHP | 12.700 | 8.51 | 7.75 | 6.55 | 4.50 | 16.4 | 17.6 | 11.80 | 1.6/1.3 | 11.0/2500 | 11.5 | 0.62 |

HP125 | 12.500 | 8.51 | 8.20 | 6.65 | 4.50 | 16.4 | 17.6 | 11.60 | 1.5/1.3 | 8.0/1819 | 8.8 | 0.61 |

HP50F7 | 50.000 | 18.00 | 15.00 | 14.00 | 10.20 | 36.0 | 37.5 | 26.00 | 4.00 | 40/9091 | 43.2 | 2.56 |

HP50F10 | 50.000 | 18.00 | 22.00 | 12.10 | 8.30 | 39.5 | 40.6 | 30.00 | 3.00 | 45/10227 | 48.0 | 2.73 |

HB55 | 55.000 | 18.00 | 22.00 | 14.00 | 10.00 | 43.4 | 44.5 | 30.00 | 4.00 | 50/11364 | 52.0 | 3.31 |

HB55F1 | 55.000 | 24.00 | 24.00 | 17.00 | 12.00 | 52.0 | 53.5 | 40.00 | 5.00 | 90/20455 | 100.0 | 6.34 |

HB38.1F8 | 38.100 | 10.16 | 9.65 | 7.10 | 5.40 | 20.4 |

| 16.00 | 2.03 | 13/2954 | 14.3 | 0.67 |

C2060H-HP | 38.100 | 11.91 | 12.70 | 6.00 | 8.31 | 29.2 | 30.2 | 17.00 | 3.25 | 24/5455 | 27.1 | 1.29 |

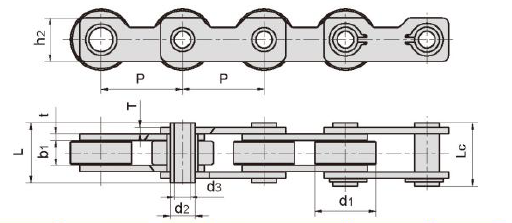

CHAIN NO. | Pitch | Roller

darneter | Width

between

inner plates | Pin

diameter | Pin length | Inner

Flate

dopth | Plate

thickness | Ultimate

tensle

strongth | Aretage

tensile

strength | Weight

per

meter | Type |

Cadena No | Paso | Diametro

casquillo | Ancho

intenor | Diametro

pasador | Longitud

pasador | Altura

placas | Ancho

placas | Resis.

rotura | Resis.

media

traccion | Peso

por

metro | Tipa |

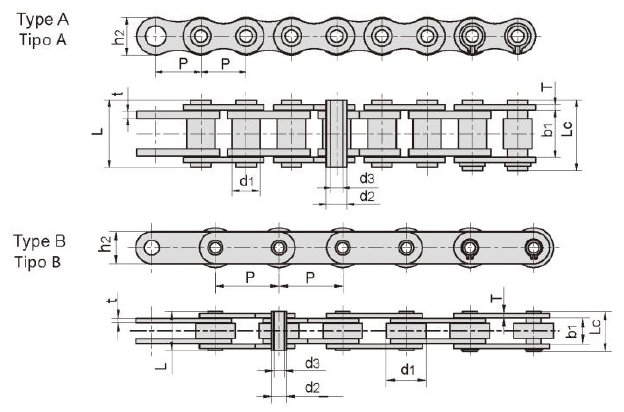

P | d1

max | b1

min | d2

max | d3

min | L

max | Lc

max | h2

max | t/T

max | Q

min | Q | q |

|

mm | mm | mm | mm | mm | mm | mm | mm | mm | kN/LB | kN | kg/m |

|

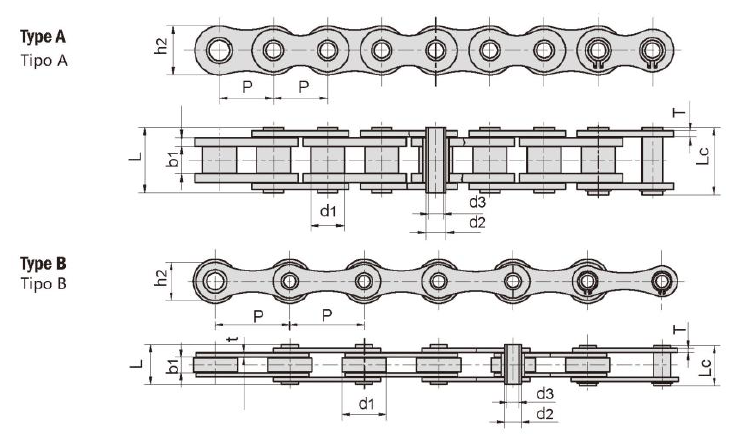

10BHB | 15.875 | 10.16 | 9.65 | 5.94 | 4.04 | 19.30 | 20.60 | 14.70 | 1.70 | 17.00/3864 | 20.80 | 0.86 | A |

12BHP | 19.050 | 12.07 | 11.68 | 6.50 | 4.00 | 21.60 | 22.80 | 15.90 | 1.85 | 23.60/5364 | 25.90 | 1.09 | A |

60HB | 19.050 | 11.91 | 12.70 | 7.00 | 5.01 | 25.50 | 26.60 | 18.00 | 2.42 | 20.00/4545 | 22.40 | 1.35 | A |

16BHBF1 | 25.400 | 15.88 | 12.70 | 9.53 | 7.05 | 30.80 | 32.20 | 23.00 | 4.15/3.1 | 40.00/9091 | 45.00 | 2.28 | A |

HB25.4 | 25.400 | 20.00 | 8.00 | 8.00 | 5.20 | 19.50 | 20.50 | 17.00 | 2.03 | 25.00/5680 | 28.00 | 1.30 | A |

HP35 | 35.000 | 20.00 | 16.00 | 13.35 | 10.20 | 30.40 | 31.60 | 26.30 | 2.50 | 23.52/5345 | 26.40 | 2.02 | A |

HB35 | 35.000 | 20.00 | 16.00 | 14.00 | 10.20 | 32.00 | 33.50 | 38.10 | 3.00 | 40.00/9091 | 45.00 | 2.39 | A |

HB38.1 | 38.100 | 20.00 | 8.00 | 8.00 | 5.30 | 19.60 | 20.70 | 17.30 | 2.03 | 28.00/5682 | 28.80 | 0.98 | B |

HB38.1F1 | 38.100 | 20.00 | 18.00 | 10.50 | 5.10 | 39.00 | 40.30 | 22.00 | 4.00 | 60.00/13636 | 64.30 | 2.59 | B |

HB38.1F3 | 38.100 | 25.40 | 12.70 | 12.00 | 8.30 | 27.00 | 28.60 | 38.10 | 2.50 | 25.00/5682 | 28.80 | 1.51 | B |

HB38.1F4 | 38.100 | 20.00 | 12.70 | 8.00 | 5.20 | 26.00 | 27.20 | 17.00 | 2.42 | 24.00/5455 | 26.90 | 1.48 | B |

HP40F4 | 40.000 | 26.00 | 10.00 | 11.40 | 8.20 | 26.50 | 28.00 | 24.00 | 3.00 | 50.00/11364 | 56.70 | 2.20 | B |

HP41.75F1 | 41.750 | 17.10 | 20.20 | 11.11 | 8.20 | 35.70 | 39.00 | 21.65 | 3.10 | 26.50/6022 | 29.20 | 1.60 | A |

HP41.75F2 | 41.750 | 17.10 | 20.20 | 11.11 | 8.20 | 35.70 | 41.00 | 25.26 | 3.10 | 49.00/11136 | 54.80 | 2.04 | A |

HP41.75F3 | 41.750 | 17.00 | 20.50 | 11.00 | 8.30 | 36.00 | 39.50 | 21.40 | 3.00 | 27.00/6136 | 28.00 | 1.62 | A |

HP50F2 | 50.000 | 31.00 | 15.00 | 13.20 | 10.20 | 36.50 | 38.00 | 25.00 | 4.00 | 40.00/9091 | 43.20 | 3.40 | B |

HB50.8 | 50.800 | 30.00 | 10.50 | 11.40 | 8.20 | 27.40 | 28.60 | 26.00 | 3.10 | 50.00/11364 | 53.60 | 2.56 | B |

CHAIN NO. | Pitch | Roller

diameter | Width

between

inner plates | Pin

diameter | Pin length | Inner

Flate

depth | Plate

thickness | Ultimate

tonile

strength | Average

tonsie

strength | Weight

per

meter | lype |

Cadena No | Paso | Diametro

rodillo | Ancho

interior | Diametro

pasador | Longitud

pasador | Altura

placas | Ancho

placas | Resis.

rotura | Resis.

media

traccion | Peso

por

metro | Tipo |

P | d1

max | bt

min | d2

max | d3

min | L

max | Lc

max | h2

max | t/T

max | Q

min | Qo | q |

|

mm | mm | mm | mm | mm | mm | mm | mm | mm | kN/LB | KN | kg/m |

|

HB50.8F4 | 50.80 | 30.00 | 10.50 | 13.6 | 8.20 | 27.40 | 28.90 | 26.0 | 3.10 | 42.00/9545 | 48.20 | 2.28 | B |

HB63 | 63.00 | 30.00 | 10.00 | 11.4 | 8.10 | 26.70 | 28.10 | 26.5 | 3.10 | 50.00/11364 | 53.60 | 2.07 | B |

HB63F1 | 63.00 | 40.00 | 10.00 | 11.4 | 8.10 | 26.70 | 28.10 | 26.5 | 3.10 | 50.00/11364 | 53.60 | 227 | B |

HB63F2 | 63.00 | 40.00 | 20.00 | 11.4 | 8.10 | 36.70 | 38.10 | 26.5 | 3.10 | 50.00/11364 | 53.60 | 3.20 | B |

HB63F3 | 63.00 | 40.00 | 15.00 | 11.4 | 8.20 | 35.60 | 37.00 | 26.5 | 4.00 | 35.00/7955 | 38.50 | 3.90 | B |

HB63F4 | 63.00 | 30.00 | 20.00 | 11.4 | 8.10 | 36.70 | 38.10 | 26.5 | 3.10 | 50.00/11364 | 53.60 | 2.97 | B |

HB63F6 | 63.00 | 30.00 | 10.00 | 11.7 | 8.20 | 26.70 | 28.10 | 26.5 | 3.10 | 50.00/11364 | 56.70 | 2.08 | B |

HB63F7 | 63.00 | 40.00 | 18.00 | 14.0 | 10.20 | 38.00 | 39.50 | 28.0 | 4.00 | 50.00/11364 | 56.70 | 4.26 | B |

HB63F8 | 63.00 | 30.00 | 20.00 | 11.7 | 8.10 | 36.50 | 38.00 | 26.5 | 3.10 | 50.00/11364 | 56.70 | 2.91 | B |

HB100 | 100.00 | 30.00 | 10.50 | 11.4 | 8.20 | 27.40 | 28.60 | 26.0 | 3.10 | 50.00/11364 | 53.60 | 1.56 | B |

12AHEF2 | 19.05 | 11.91 | 12.70 | 7.0 | 5.10 | 26.50 | 27.60 | 18.0 | 2.42 | 20/4545 | 22.40 | 1.39 | A |

12BHPF6SLR | 19.05 | 12.07 | 11.68 | 6.5 | 4.04 | 22.30 | 23.50 | 15.9 | 1.85 | 23.6/5364 | 25.96 | 1.12 | A |

HP38.1F9 | 38.10 | 22.20 | 12.70 | 11.0 | 8.15 | 26.50 | 27.50 | 18.0 | 2.50 | 22/5000 | 24.40 | 1.46 | B |

HDC16500HP | 50.00 | 30.00 | 10.50 | 11.4 | 8.20 | 27.40 | 28.60 | 26.0 | 3.10 | 50.00/11364 | 53.60 | 2.23 | B |

HB50F4 | 50.00 | 30.00 | 10.00 | 16.0 | 8.00 | 26.60 | 30.00 | 25.4 | 3.00 | 60/13635 | 67.20 | 2.03 | B |

HB50.8F14 | 50.80 | 30.00 | 10.00 | 16.0 | 8.00 | 26.60 | 30.00 | 25.4 | 3.00 | 60/13635 | 67.20 | 201 | B |

HB100F8 | 100.00 | 30.00 | 10.00 | 16.0 | 8.00 | 26.60 | 30.00 | 25.4 | 3.00 | 60/13635 | 67.20 | 1.37 | B |

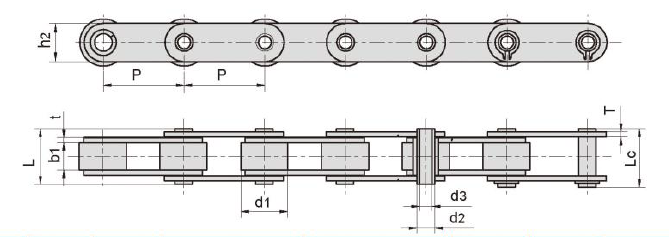

CHAIN NO. | Pitch | Roller

diamete | Width

between

inner plates | Pin

diameter | Pin length | Inner

Plate

depth | Plate

thickness | Ulimate

tensile

strength | Avelage

tensile

strength | Weight

per

meter |

Cadena No | Paso | Diametro

rodillo | Ancho

interior | Diametro

pasador | Longitud

pasador | Altura

placas | Ancho

placas | Resis.

rotura | Resis.

media

tracción | Peso

por

metro |

P | di

max | b1

min | dz

max | ds

min | L

max | Lc

max | h2

max | VT

max | Q

min | Q | q |

mm | mm | mm | mm | mm | mm | mm | mm | mm | KN/LB | KN | kg/m |

C2042HP | 25.40 | 15.88 | 7.85 | 5.63 | 4.00 | 16.5 | 17.6 | 12.00 | 1.50 | 11.0/2500 | 12.6 | 0.78 |

C2052HP | 31.75 | 19.05 | 9.53 | 7.22 | 5.12 | 20.5 | 21.8 | 15.00 | 2.03 | 20.4/4636 | 22.8 | 1.25 |

C2062HP | 38.10 | 22.23 | 12.70 | 8.31 | 6.00 | 25.8 | 26.8 | 17.00 | 2.42 | 24.0/5455 | 27.1 | 1.72 |

C2082HP | 50.80 | 28.58 | 15.75 | 11.40 | 8.05 | 32.4 | 33.8 | 24.00 | 3.25 | 50.0/11364 | 52.0 | 2.82 |

C2042H-HP | 25.40 | 15.88 | 7.85 | 5.63 | 4.00 | 18.8 | 19.9 | 12.00 | 2.03 | 11.0/2500 | 13.2 | 0.95 |

C2052HPF1 | 31.75 | 19.05 | 9.40 | 7.03 | 5.12 | 20.0 | 21.5 | 15.30 | 1.85 | 15.0/3409 | 17.3 | 1.21 |

C2052HPF3 | 31.75 | 19.05 | 9.53 | 7.02 | 5.13 | 20.1 | 21.6 | 15.09 | 2.03 | 19.6/4455 | 21.6 | 1.20 |

C2050H-HP | 31.75 | 19.05 | 9.53 | 7.22 | 5.12 | 22.1 | 23.4 | 15.00 | 2.42 | 20.4/4545 | 23.5 | 1.44 |

C2062H-HP | 38.10 | 22.23 | 12.70 | 8.31 | 6.00 | 29.2 | 30.2 | 17.00 | 3.25 | 24.0/5455 | 27.6 | 1.99 |

C2082H-HP | 50.80 | 28.58 | 15.75 | 11.40 | 8.05 | 35.7 | 37.0 | 24.00 | 4.00 | 50.0/11364 | 56.5 | 3.34 |

HP40 | 40.00 | 22.00 | 8.75 | 9.00 | 6.00 | 23.0 | 24.2 | 18.00 | 2.50 | 27.0/4545 | 28.0 | 1.49 |

HB40F1 | 40.00 | 22.00 | 9.00 | 9.00 | 6.00 | 23.0 | 24.5 | 18.00 | 2.50 | 20.0/4546 | 22.0 | 1.58 |

HB414 | 41.40 | 25.40 | 15.00 | 13.80 | 10.50 | 35.5 | 37.0 | 32.00 | 4.00 | 45.0/10227 | 48.0 | 4.20 |

HPS0 | 50.00 | 31.00 | 14.50 | 13.20 | 10.40 | 31.1 | 325 | 25.00 | 3.10 | 30.0/6818 | 34.2 | 3.29 |

HP50F4 | 50.00 | 31.00 | 15.00 | 13.20 | 10.20 | 36.5 | 38.0 | 25.00 | 4.00 | 40.0/9091 | 44.8 | 3.73 |

HB50 | 50.00 | 31.00 | 15.00 | 14.00 | 10.20 | 36.0 | 37.5 | 25.00 | 4.00 | 40.0/9091 | 43.2 | 3.98 |

HB50.8F8 | 50.80 | 32.00 | 20.00 | 19.10 | 12.40 | 44.6 | 46.4 | 40.00 | 5.0/4.0 | 100.0/22727 | 108.0 | 6.75 |

C1655HP | 50.80 | 30.00 | 10.50 | 13.00 | 8.20 | 27.4 | 28.9 | 26.00 | 3.10 | 42.0/9545 | 48.2 | 2.72 |

HP50.8 | 50.80 | 26.00 | 15.88 | 20.00 | 14.30 | 41.0 | 42.2 | 38.10 | 4.80 | 100.0/22727 | 108.0 | 5.32 |

HB50.8F9 | 50.80 | 35.00 | 12.00 | 15.50 | 10.20 | 36.0 | 37.3 | 30.00 | 5.00 | 70.0/15909 | 77.0 | 4.92 |

63HPF1 | 63.00 | 40.00 | 15.00 | 16.00 | 12.10 | 35.0 | 36.2 | 28.50 | 4.00 | 50.0/11364 | 56.7 | 4.20 |

HDC4202HP | 50.80 | 31.80 | 15.00 | 14.00 | 10.10 | 36.3 | 39.0 | 26.00 | 3.80 | 42.0/9545 | 51.6 | 3.75 |

HDC4203HP | 76.20 | 31.80 | 15.00 | 14.00 | 10.10 | 36.3 | 39.0 | 26.00 | 3.80 | 42.0/9545 | 47.1 | 3.01 |

CHAIN NO. | Pitch | Roller

diameter | Width

between

inner plater | Pin

diameter | Pin length | Inner

Plate

depth | Plate

thickress | Ultirnate

tenaile

strength | Avelage

tensie

strength | Weight

per

meter |

Cadena No | Paso | Diámetro

rcdillo | Ancho

interior | Diametro

pasador | Longitud

pasador | Altura

placas | Ancho

placas | Resis.

rotura | Resis

media

tracción | Pes0

por

metro |

P | d1

max | bt

min | d2

max | d3

min | L

max | Lc

max | h2

max | t/T

max | Q

min | QB | q |

mm | mm | mm | mm | mm | mm | mm | mm | mm | kN/LB | kN | kg/m |

HDC42035HP | 88.9 | 31.80 | 15.00 | 14.00 | 10.1 | 36.3 | 39.0 | 26.0 | 3.8 | 42.0/9545 | 51.1 | 2.79 |

HDC4204HP | 101.6 | 31.80 | 15.00 | 14.00 | 10.1 | 36.3 | 39.0 | 26.0 | 3.8 | 42.0/9545 | 51.6 | 2.63 |

HDC8403HP | 76.2 | 47.60 | 19.00 | 19.05 | 13.6 | 43.8 | 46.3 | 39.0 | 5.1/3.8 | 84.3/19159 | 130.3 | 6.81 |

HDC8404HP | 101.6 | 47.60 | 19.00 | 19.05 | 13.6 | 43.8 | 46.3 | 39.0 | 5.1/3.8 | 84.3/19159 | 130.3 | 5.78 |

HDC8406HP | 152.4 | 47.60 | 19.00 | 19.05 | 13.6 | 43.8 | 46.3 | 39.0 | 5.1/3.8 | 84.0/19091 | 130.3 | 5.18 |

HB38.1F2 | 38.1 | 25.40 | 12.70 | 9.50 | 6.6 | 26.6 | 28.0 | 19.1 | 23 | 20.0/4545 | 22.4 | 2.07 |

HB50.8F3 | 50.8 | 30.00 | 16.00 | 14.00 | 9.0 | 36.4 | 37.5 | 25.5 | 3.1 | 420/9545 | 47.0 | 3.20 |

HB75 | 75.0 | 40.00 | 22.00 | 18.00 | 12.2 | 42.0 | 44.0 | 35.0 | 4.0 | 60.0/13636 | 72.0 | 5.57 |

HB76.2 | 76.2 | 31.75 | 15.50 | 12.70 | 9.5 | 35.5 | 37.0 | 26.0 | 4.0 | 420/9545 | 49.2 | 3.25 |

HE76.2F2 | 76.2 | 47.60 | 20.00 | 24.00 | 18.5 | 44.5 | 46.1 | 40.0 | 5.0/4.0 | 79.0/17953 | 92.5 | 6.77 |

HB80 | 80.0 | 50.00 | 20.00 | 24.00 | 18.5 | 44.5 | 46.1 | 40.0 | 5.0/4.0 | 79.0/17953 | 92.5 | 6.81 |

HP100 | 100.0 | 45.00 | 22.00 | 16.00 | 12.0 | 46.0 | 47.5 | 35.0 | 5.0 | 75.0/17044 | 90.0 | 6.20 |

HP100F1 | 100.0 | 45.00 | 22.00 | 18.00 | 12.0 | 47.2 | 48.5 | 35.0 | 5.0 | 75.0/17044 | 90.0 | 6.15 |

CHAIN NO. | Pitch | Roller

diameter | Width

between

inner plates | Pin

dlameter | Pin length | Plate

depth | Plate

thickness | Ultimate

tensile

strength | Average

tensile

strength | Weight

per

meter |

Cadena No | Paso | Diámetro

rodillo | Ancho

interior | Diámetro

pasador | Longitud

pasador | Altura

placas | Ancho

placas | Resis.

rolura | Resis.

media

tracción | Peso

por

metro |

P | d1

max | bi

min | dz

max | d3

min | L

max | Lc

max | h2

max | t/T

max | Q

min | Qo | q |

mm | mm | mm | mm | mm | mm | mm | mm | mm | KN/LB | KN | kg/m |

HB50.8F1 | 50.8 | 38.1 | 15.7 | 15.5 | 10.3 | 35.2 | 36.7 | 27.2 | 4.00 | 55.46/51650 | 58.8 | 4.97 |

CHAIN NO. | Pitch | Roller

diameter | Width

between

inner plates | Pin

diameter | Pin length | Inner

Plate

depth | Plate

thickness | Ullimale

tefisle

strength | Average

tersile

strength | Weight

per

meter |

Cadena No | Paso | Diametro

rodillo | Ancho

interior | Diametro

pasador | Longitud

pasador | Altura

placas | Altura

placas | Ancho

placas | Resis.

media

tracción | Pesp

por

metro |

P | d1

max | b1

min | d

max | d3

min | L

max | Lc

max | h2

max | t/T

max | Q

min | Q | q |

mm | mm | mm | mm | mm | mm | mm | mm | mm | kN/LB | KN | kg/m |

HP101.6F1 | 101.60 | 47.60 | 19.00 | 19.00 | 13.20 | 46.2 | 48.0 | 40.0 | 5.0/4.0 | 53.0/12045 | 58.20 | 6.09 |

HP101.6F2 | 101.60 | 66.70 | 25.40 | 26.90 | 20.10 | 592 | 60.7 | 51.0 | 7.1/5.1 | 150.0/34088 | 160.00 | 14.23 |

HP152 | 152.40 | 66.70 | 25.40 | 26.90 | 19.56 | 57.2 | 59.5 | 50.8 | 7.1/5.1 | 94.0/21362 | 107.80 | 9.90 |

HP152.4F1 | 152.40 | 47.60 | 19.00 | 19.00 | 13.20 | 46.2 | 48.0 | 40.0 | 5.0/4.0 | 54.0/12270 | 59.50 | 5.00 |

C2102HP | 63.50 | 39.67 | 18.90 | 13.60 | 9.50 | 403 | 42.0 | 30.0 | 4.00 | 60.0/13636 | 72.00 | 5.13 |

C2062H-HPF3 | 38.10 | 22.23 | 12.70 | 8.31 | 6.00 | 25.8 | 26.8 | 17.0 | 2.42 | 24.0/5455 | 27.10 | 1.72 |

HP130 | 130.00 | 40.00 | 21.00 | 18.10 | 12.10 | 41.3 | 42.5 | 35.0 | 3.80 | 80.0/18183 | 89.60 | 4.21 |

HB50.8F12 | 50.80 | 28.58 | 16.00 | 14.00 | 9.00 | 36.4 | 37.5 | 25.5 | 3.50 | 42.0/9545 | 47.00 | 3.26 |

HB25.4F2 | 25.40 | 15.89 | 17.26 | 9.00 | 6.35 | 31.3 | 32.5 | 20.0 | 2.50 | 20.0/4545 | 22.40 | 1.97 |

HB50.8F11 | 50.80 | 38.10 | 16.00 | 13.80 | 9.70 | 37.2 | 39.5 | 25.4 | 3.90 | 57.0/12953 | 63.84 | 5.01 |

HB63F11 | 63.00 | 40.00 | 20.00 | 20.00 | 18.00 | 42.5 | 43.5 | 42.0 | 4.00 | 46.0/10454 | 50.60 | 5.83 |

HB65 | 65.00 | 45.00 | 20.00 | 25.00 | 18.00 | 38.0 | 40.0 | 40.0 | 3.00 | 46.0/10454 | 50.60 | 4.49 |

HB63.5F1 | 63.50 | 32.00 | 15.00 | 16.00 | 12.20 | 32.0 | 33.0 | 25.0 | 3.00 | 20.4/4636 | 22.80 | 2.69 |

HB63F12 | 63.00 | 30.00 | 10.00 | 11.40 | 8.10 | 26.7 | 28.1 | 26.5 | 3.10 | 50.0/11364 | 56.50 | 2.39 |

HB100F10 | 100.00 | 45.00 | 33.00 | 18.00 | 12.10 | 48.5 | 49.7 | 35.0 | 5.00 | 75.0/17046 | 84.70 | 6.05 |

HB100F11 | 100.00 | 40.00 | 20.60 | 16.00 | 12.50 | 42.1 | 43.4 | 35.0 | 4.00 | 75.0/17046 | 84.70 | 4.58 |

HB38.1F6-R | 38.10 | 25.40 | 15.20 | 14.00 | 10.20 | 34.5 | 36.5 | 27.0 | 3.70 | 45.0/10228 | 49.50 | 3.20 |

HB25.4F4 | 25.40 | 20.00 | 11.00 | 12.00 | 8.35 | 27.0 | 28.4 | 24.0 | 3.00 | 32.0/7273 | 35.80 | 2.48 |

HB100F9 | 100.00 | 45.00 | 32.80 | 18.00 | 12.40 | 49.0 | 49.0 | 35.0 | 5.00 | 75.0/17046 | 84.70 | 6.14 |

HB100F7 | 100.00 | 30.00 | 15.00 | 16.00 | 12.30 | 36.5 | 37.8 | 35.0 | 4.00 | 75.0/17046 | 84.70 | 3.49 |

HB100F3 | 100.00 | 30.00 | 24.00 | 1595 | 10.30 | 46.0 | 47.3 | 35.0 | 4.00 | 75.0/17046 | 84.70 | 4.04 |

HB50.42 | 50.42 | 37.30 | 15.00 | 14.00 | 10.20 | 36.0 | 37.5 | 26.2 | 4.00 | 40.0/9090 | 44.80 | 4.46 |

CHAIN NO. | Pitch | Roller

diameter | Width

betwocn

innet plates | Pin

diameter | Pin length | Inner

Plate

depth | Plate

thickness | Ultimate

tersle

strength | Average

tersile

strength | Weight

per

metel | Type |

Cadena No | Paso | Diametro

rodillo | Ancho

intenor | Diámetro

pasador | Longitud

pasador | Altura

placas | Ancho

placas | Resis

rotura | Resis

media

traccion | Peso

por

metro | Tipo |

P | d1

max | b1

min | 6

max | d3

min | L

max | lc

max | h2

max | t/T

max | Q

min | Q® | q |

|

mm | mm | mm | mm | mm | mm | mm | mm | mm | KN/LB | KN | kg/m |

|

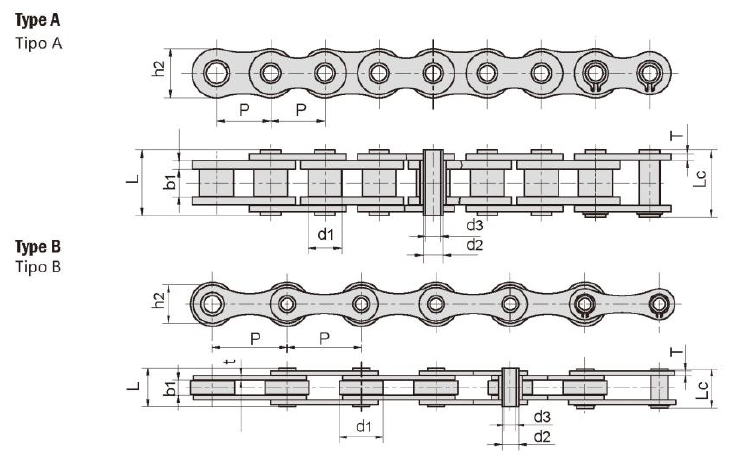

08BHPF2 | 12.700 | 8.51 | 13.20 | 6.65 | 5.20 | 18.0 | 19.2 | 11.8 | 1.6/1.3 | 10.0/2273 | 11.4 | 0.50 | A |

08BHPF3 | 12.700 | 8.51 | 13.40 | 6.65 | 4.00 | 19.0 | 20.2 | 11.8 | 1.70 | 14.0/3182 | 16.8 | 0.69 | A |

HB12.7 | 12.700 | 8.51 | 13.40 | 6.65 | 4.10 | 19.0 | 20.2 | 11.8 | 1.70 | 14.0/3182 | 16.8 | 0.69 | A |

08EHPF8 | 12.700 | 8.51 | 11.30 | 6.30 | 4.50 | 16.7 | 18.5 | 11.8 | 1.60 | 11.0/2500 | 12.1 | 0.80 | A |

40HPF1-D3 | 12.700 | 8.51 | 11.60 | 6.35 | 4.36 | 20.6 | 20.6 | 12.0 | 1.50 | 11.0/2500 | 12.1 | 0.77 | A |

10BHPF1 | 15.875 | 10.16 | 13.41 | 7.03 | 5.00 | 19.2 | 20.2 | 14.0 | 1.85 | 17.0/3864 | 20.6 | 0.83 | A |

10BHPF2 | 15.875 | 10.16 | 10.40 | 7.03 | 5.00 | 17.0 | 18.0 | 14.0 | 1.85 | 15.0/3409 | 17.3 | 0.74 | A |

12BHPF1 | 19.050 | 12.07 | 16.00 | 8.03 | 5.40 | 22.7 | 23.9 | 15.8 | 1.85 | 25.0/5682 | 28.8 | 1.09 | A |

16BHPF1 | 25.400 | 15.88 | 25.58 | 11.50 | 8.10 | 36.5 | 37.6 | 21.0 | 4.15/3.1 | 45.0/10227 | 52.2 | 2.21 | A |

50HPF1 | 15.875 | 10.16 | 13.60 | 7.03 | 5.13 | 20.7 | 21.9 | 14.4 | 2.03 | 18.0/4091 | 21.6 | 0.92 | A |

60HPF2 | 19.050 | 11.91 | 11.23 | 5.63 | 4.05 | 16.5 | 17.6 | 10.4 | 1.50 | 10.0/2273 | 10.8 | 0.62 | A |

C12BHPF9 | 19.050 | 12.07 | 15.80 | 8.03 | 5.00 | 22.4 | 23.9 | 16.1 | 1.85 | 25.0/5682 | 28.8 | 1.26 | B |

12BHPF9 | 19.050 | 12.07 | 15.80 | 8.03 | 5.00 | 22.4 | 23.9 | 16.1 | 1.58 | 25.0/5682 | 28.8 | 1.18 | A |

60HPF3 | 19.050 | 11.91 | 17.20 | 8.40 | 6.10 | 24.7 | 26.0 | 18.0 | 2.03 | 20.0/4546 | 24.0 | 1.54 | A |

63HP | 63.000 | 40.00 | 23.50 | 16.00 | 12.00 | 35.3 | 38.3 | 28.6 | 4.00 | 65.0/14773 | 71.5 | 4.14 | B |

63HPF2 | 63.000 | 40.00 | 25.80 | 14.00 | 8.08 | 39.1 | 41.1 | 20.0 | 5.00 | 50.0/11364 | 65.7 | 4.17 | B |

63HPF4 | 63.000 | 40.00 | 23.50 | 16.00 | 12.30 | 34.7 | 37.7 | 28.6 | 4.00 | 44.0/10000 | 57.2 | 4.13 | B |

63HPF6 | 63.000 | 40.00 | 28.94 | 16.00 | 10.30 | 41.8 | 43.4 | 28.6 | 4.00 | 44.0/10000 | 572 | 5.18 | B |

63HPF11 | 63.000 | 40.00 | 23.50 | 16.00 | 12.20 | 34.7 | 37.7 | 28.6 | 4.00 | 65.0/147333 | 71.5 | 4.25 | B |

63HPF12 | 63.000 | 40.00 | 23.50 | 16.00 | 12.20 | 34.7 | 37.7 | 28.0 | 4.00 | 44.0/10000 | 57.2 | 4.02 | B |

C2122HPF1 | 76.200 | 47.60 | 29.00 | 17.81 | 12.70 | 43.3 | 44.7 | 38.1 | 4.80 | 53.3/12123 | 59.2 | 7.05 | B |

FAQ: Frequently Asked Questions

Q: Does a hollow pin chain have the same tensile strength as a solid pin chain?

A: No, a hollow pin chain typically has about 15% to 20% less tensile strength than its solid pin counterpart of the same size. However, for conveyor applications where flexibility and attachment mounting are the priority, the strength-to-weight ratio is often superior.

Q: Can I use your hollow pin chain in high-temperature ovens?

A: Yes, we offer a specialized "High-Heat" series made from alloy steels that can withstand temperatures up to 250°C (480°F). For even higher temperatures, our stainless steel series is recommended.

Q: Are special sprockets required for hollow pin chains?

A: No, our hollow pin chains are designed to run on standard ANSI or ISO sprockets, provided the pitch and roller diameter match. This makes upgrading your current system simple and cost-effective.

Q: Is it possible to get the chain in a "self-lubricating" version?

A: Yes, we can manufacture the hollow pin chain with oil-impregnated sintered bushings (Lube-Free series), which is ideal for applications where external lubrication might contaminate the product, such as in paper or textile manufacturing.

Would you like me to create a comparison chart showing the performance differences between carbon steel and stainless steel hollow pin chains for your specific environment?

English

Español

العربية

Français

Русский

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

አማርኛ

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Kiswahili

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

Հայերեն

עברית

Latine

Dansk

اردو

Shqip

বাংলা

Hrvatski

Afrikaans

Gaeilge

Eesti keel

Māori

සිංහල

नेपाली

Oʻzbekcha

latviešu

অসমীয়া

Aymara

Azərbaycan dili

Bamanankan

Euskara

Беларуская мова

भोजपुरी