Product Description

In the world of mechanical power transmission, the cost of downtime far exceeds the cost of the chain itself. Our Short Pitch Precision Roller Chain is designed to mitigate this risk. Each link is a testament to precision metallurgy, crafted to transform raw power into smooth, rhythmic motion.

Imagine a production floor where the rhythmic "hum" of the conveyor replaces the jarring "clatter" of inferior chains. That is the experience we provide. Our chains feature seamless rollers and solid bushings, which significantly reduce the friction that leads to heat buildup and premature failure. By choosing this A-Series chain, you are investing in a product that feels substantial in the hand—smooth, cold-forged steel with a flawless finish—and performs even better under pressure. We don't just sell steel; we sell the peace of mind that comes from knowing your assembly line will never miss a beat.

Key Features and Highlights

Our A-Series chains are defined by four pillars of excellence that set them apart from standard market offerings:

Shot-Peened Resilience: Every side plate and roller undergoes a high-velocity shot-peening process. This creates a compressive stress layer that inhibits fatigue cracks, extending the fatigue life of the chain by up to 30%.

Four-Point Riveting: Our pins are secured using a proprietary four-point riveting technique. This ensures maximum side-plate security and prevents pin rotation even under extreme shock loads.

Solid Bushing Technology: Unlike curled bushings that can develop "flat spots," our solid bushings maintain perfect roundness, ensuring consistent contact with the pin and drastically reducing wear-related stretching.

High-Carbon 40Mn Steel: We utilize premium carbon steel, heat-treated in a controlled atmosphere to achieve the perfect balance of surface hardness and core toughness.

Manufacturing Mastery & Material Science

The secret to a high-performance roller chain lies beneath the surface. We utilize an advanced heat-treatment process known as Isothermal Quenching. This process ensures that the internal molecular structure of the steel is uniform, preventing the brittleness often found in cheaper alternatives.

Raw Material Selection: We source only certified 40Mn and 304/316 stainless steel, verifying the chemical composition before production begins.

Precision Cold Forging: Rollers and bushings are cold-forged to exact tolerances, ensuring the chain engages the sprocket teeth with surgical precision, reducing noise and vibration.

Automated Assembly: Using Swiss-designed automated assembly lines, we eliminate human error, ensuring every link is identical in tension and alignment.

The "Pre-Stretch" Protocol: Every meter of chain is subjected to a "breaking-in" load. This eliminates the "initial stretch" usually seen in the first few hours of operation, meaning you won't have to adjust your tensioners shortly after installation.

Versatile Application Dimensions

Our Short Pitch Precision Roller Chains are the preferred choice across a vast spectrum of industries. Their adaptability makes them a universal solution for modern engineering:

Food & Beverage Packaging: Used in high-speed filling machines where hygiene and precision timing are non-negotiable.

Automotive Assembly Lines: Providing the heavy-lifting capabilities required for chassis and engine transport systems.

Agricultural Machinery: Built to withstand the dust, grit, and varying temperatures of harvesting and tilling equipment.

Logistics & Material Handling: Driving the conveyor belts in massive distribution centers where 24/7 reliability is the only metric that matters.

Maintenance & Installation Guide

A precision chain deserves precision care. To maximize your ROI, follow these expert guidelines derived from decades of engineering experience:

Alignment is Critical: Ensure that sprockets are perfectly aligned. Misalignment causes side-plate wear and increases energy consumption.

Lubrication Schedule: Use high-quality non-detergent petroleum-based oil. In dusty environments, consider dry-film lubricants to prevent grit from sticking to the pins.

Wear Monitoring: Replace the chain when the total elongation reaches 1.5% to 2% of the original length to prevent damage to your expensive sprockets.

Proper Tensioning: A chain that is too tight will wear out bearings; a chain that is too loose will whip and vibrate. Aim for a mid-span slack of 2-4% of the center distance.

Why Choose Us?

Partnering with us means more than just buying a product; it means gaining a technical ally. We understand that in your industry, efficiency is the currency of success.

Global Compliance: Our products meet and often exceed ANSI, DIN, and ISO standards, ensuring seamless integration into your existing systems.

Decades of Expertise: Our engineering team brings over 20 years of specialized experience in power transmission, offering custom solutions for unique torque and environment challenges.

Rapid Fulfillment: We maintain a massive inventory of standard A-Series sizes, allowing for immediate dispatch to keep your project on schedule.

E-E-A-T Certified Quality: Our testing labs conduct salt spray tests, tensile strength tests, and hardness mapping on every batch, providing full traceability and absolute reliability.

Technical Specifications & Parameter Table

DIN/ISO

CHAIN NO. | ANSI

CHAIN NO. | Pitch | Roller

diameter | Width

between

inner plates | Pin

diameter | Pin length | Inner

plate

depth | Plate

thickness | Ultimate

tensile

strength | Average

tensile

strength | Weight

per meter |

DIN/ISO

Cadena

No | ANSI

Cadena

No | Paso | Diámetro

rodillo | Ancho

interior | Diámetro

pasador | Longitud pasador | Altura

placas | Ancho

placas | Resis.

rotura | Resis.

media

tracción | Peso

por

metro |

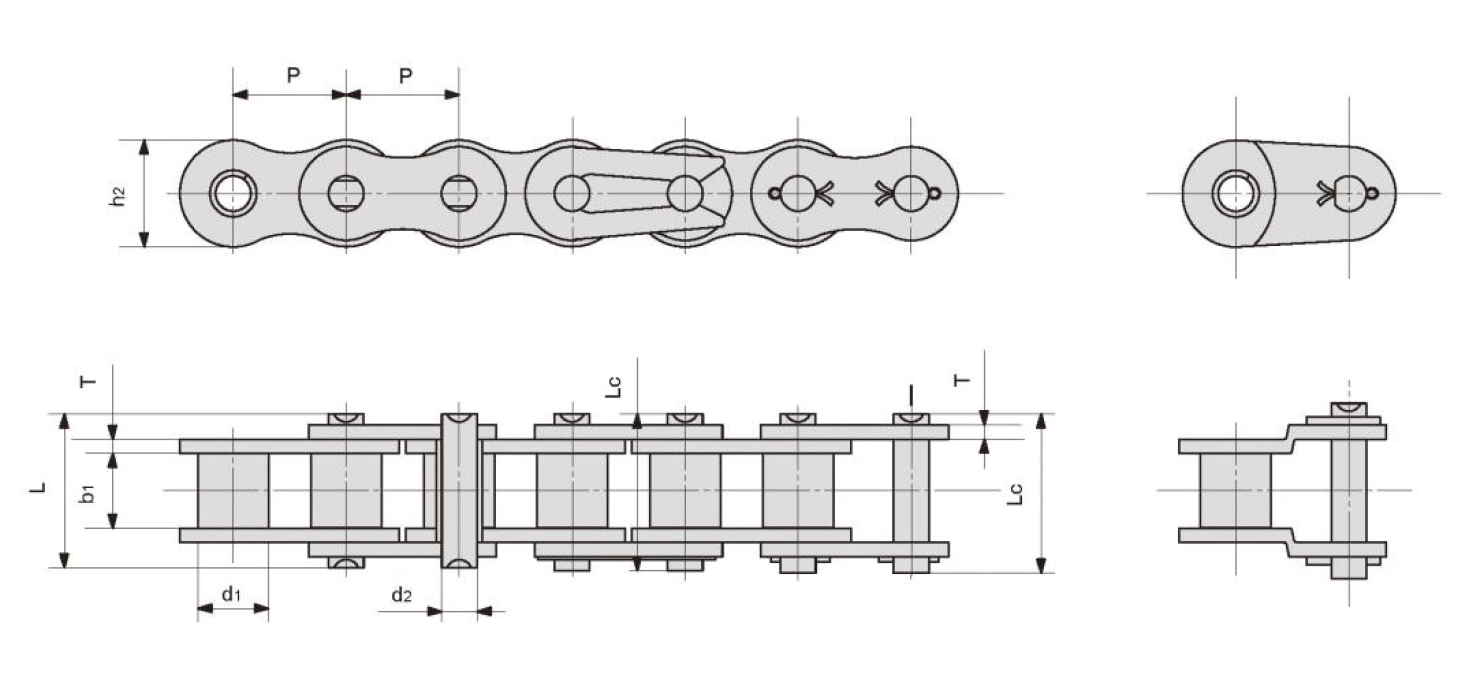

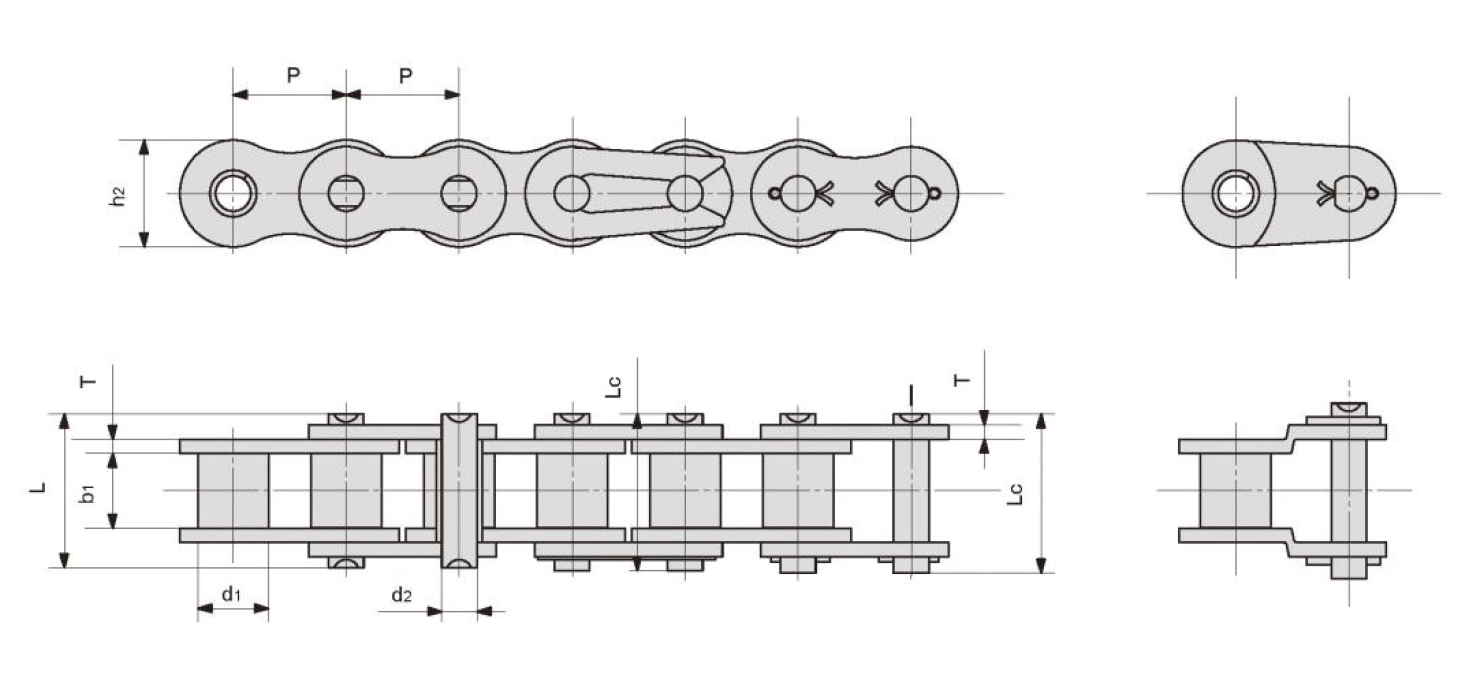

| P | d1

max | b1

min | d2

max | L

max | Lc

max | h2

max | T

max | Q

min | Qo | q |

| mm | mm | mm | mm | mm | mm | mm | mm | kN/LB | kN | kg/m |

| *03C | *15 | 4.7625 | 2.48 | 2.38 | 1.62 | 6.10 | 6.90 | 4.30 | 0.60 | 1.80/409 | 2.0 | 0.08 |

| *04C-1 | *25 | 6.350 | 3.30 | 3.18 | 2.31 | 7.90 | 8.40 | 6.00 | 0.80 | 3.50/795 | 4.6 | 0.15 |

| *06C-1 | *35 | 9.525 | 5.08 | 4.77 | 3.58 | 12.40 | 13.17 | 9.00 | 1.30 | 7.90/1795 | 10.8 | 0.33 |

| 085-1 | 41 | 12.700 | 7.77 | 6.25 | 3.58 | 13.75 | 15.00 | 9.91 | 1.30 | 6.67/1516 | 12.6 | 0.41 |

| 08A-1 | 40 | 12.700 | 7.95 | 7.85 | 3.96 | 16.60 | 17.80 | 12.00 | 1.50 | 14.10/3205 | 17.5 | 0.62 |

| 10A-1 | 50 | 15.875 | 10.16 | 9.40 | 5.08 | 20.70 | 22.20 | 15.09 | 2.03 | 22.20/5045 | 29.4 | 1.02 |

| 12A-1 | 60 | 19.050 | 11.91 | 12.57 | 5.94 | 25.90 | 27.70 | 18.00 | 2.42 | 31.80/7227 | 41.5 | 1.50 |

| 16A-1 | 80 | 25.400 | 15.88 | 15.75 | 7.92 | 32.70 | 35.00 | 24.00 | 3.25 | 56.70/12886 | 69.4 | 2.60 |

| 20A-1 | 100 | 31.750 | 19.05 | 18.90 | 9.53 | 40.40 | 44.70 | 30.00 | 4.00 | 88.50/20114 | 109.2 | 3.91 |

| 24A-1 | 120 | 38.100 | 22.23 | 25.22 | 11.10 | 50.30 | 54.30 | 35.70 | 4.80 | 127.00/28864 | 156.3 | 5.62 |

| 28A-1 | 140 | 44.450 | 25.40 | 25.22 | 12.70 | 54.40 | 59.00 | 41.00 | 5.60 | 172.40/39182 | 212.0 | 7.50 |

| 32A-1 | 160 | 50.800 | 28.58 | 31.55 | 14.27 | 64.80 | 69.60 | 47.80 | 6.40 | 226.80/51545 | 278.9 | 10.10 |

| 36A-1 | 180 | 57.150 | 35.71 | 35.48 | 17.46 | 72.80 | 78.60 | 53.60 | 7.20 | 280.20/63682 | 341.8 | 13.45 |

| 40A-1 | 200 | 63.500 | 39.68 | 37.85 | 19.85 | 80.30 | 87.20 | 60.00 | 8.00 | 353.80/80409 | 431.6 | 16.15 |

| 48A-1 | 240 | 76.200 | 47.63 | 47.35 | 23.81 | 95.50 | 103.00 | 72.39 | 9.50 | 510.30/115977 | 622.5 | 23.20 |

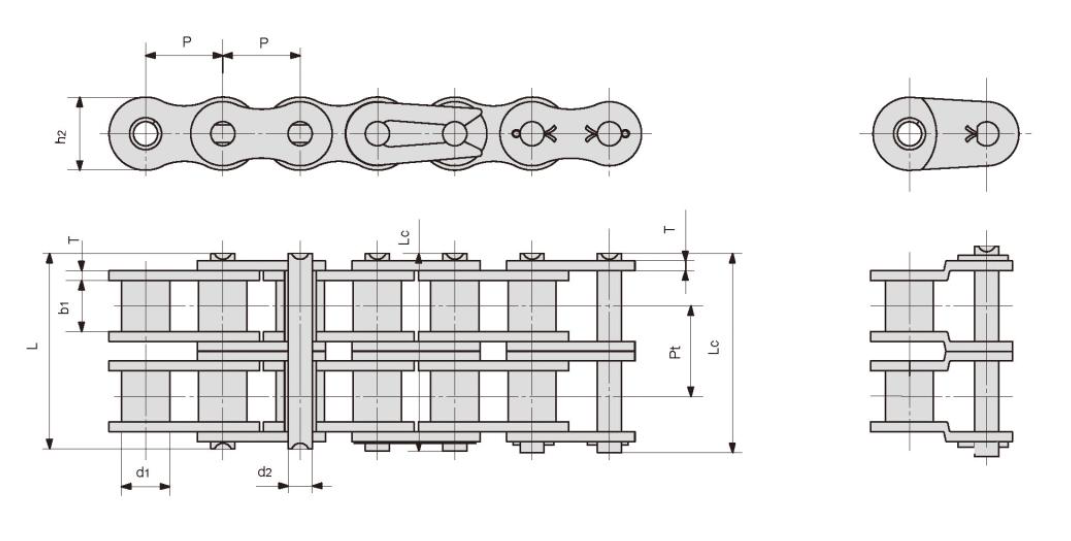

DIN/ISO

CHAIN NO. | ANSI

CHAIN NO. | Pitch | Roller

diameter | Width

between

inner plates | Pin

diameter | Pin length | Inner

plate

depth | Plate

thickness | Transverse

pitch | Ultimate

tensile

strength | Average

tensile

strength | Weight

per meter |

DIN/ISO

Cadena

No | ANSI

Cadena

No | Paso | Diámetro

rodillo | Ancho

interior | Diámetro

pasador | Longitud pasador | Altura

placas | Ancho

placas | Paso

transversal | Resis.

rotura | Resis.

media

tracción | Peso

por

metro |

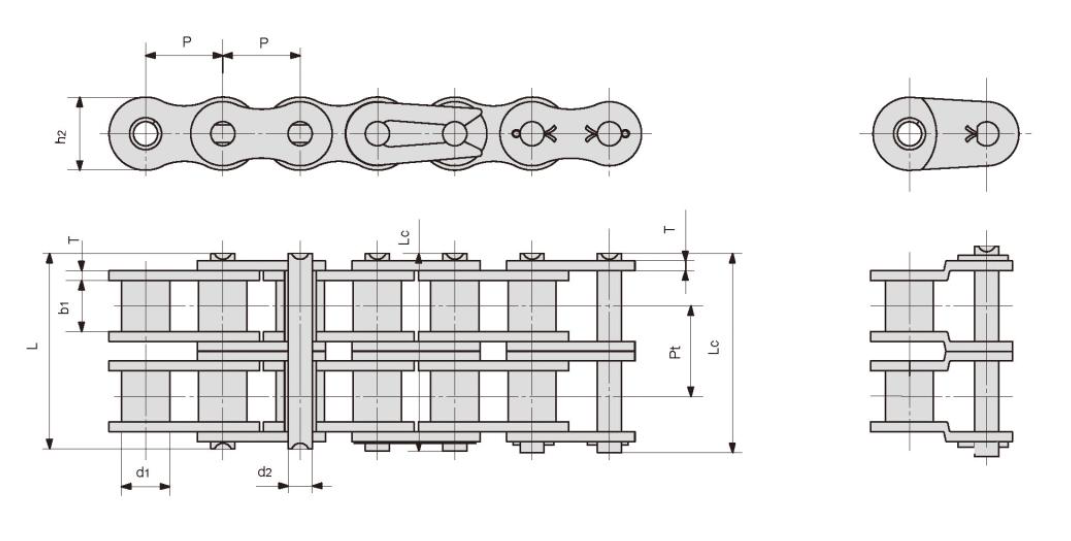

| P | d1

max | b1

min | d2

max | L

max | Lc

max | h2

max | T

max | Pt | Q

min | Qo | q |

| mm | mm | mm | mm | mm | mm | mm | mm | mm | kN/LB | KN | kg/m |

| *04C-2 | *25-2 | 6.350 | 3.30 | 3.18 | 2.31 | 14.5 | 15.0 | 6.00 | 0.80 | 6.40 | 7.00/1591 | 8.6 | 0.28 |

| *06C-2 | *35-2 | 9.525 | 5.08 | 4.77 | 3.58 | 22.5 | 23.3 | 9.00 | 1.30 | 10.13 | 15.80/3591 | 19.7 | 0.63 |

| 085-2 | 41-2 | 12.700 | 7.77 | 6.25 | 3.58 | 25.7 | 26.9 | 9.91 | 1.30 | 11.95 | 13.34/3032 | 16.9 | 0.81 |

| 08A-2 | 40-2 | 12.700 | 7.95 | 7.85 | 3.96 | 31.0 | 32.2 | 12.00 | 1.50 | 14.38 | 28.20/6409 | 35.9 | 1.12 |

| 10A-2 | 50-2 | 15.875 | 10.16 | 9.40 | 5.08 | 38.9 | 40.4 | 15.09 | 2.03 | 18.11 | 44.40/10091 | 58.1 | 2.00 |

| 12A-2 | 60-2 | 19.050 | 11.91 | 12.57 | 5.94 | 48.8 | 50.5 | 18.00 | 2.42 | 22.78 | 63.60/14455 | 82.1 | 2.92 |

| 16A-2 | 80-2 | 25.400 | 15.88 | 15.75 | 7.92 | 62.7 | 64.3 | 24.00 | 3.25 | 29.29 | 133.40/25773 | 141.8 | 5.15 |

| 20A-2 | 100-2 | 31.750 | 19.05 | 18.90 | 9.53 | 76.4 | 80.5 | 30.00 | 4.00 | 35.76 | 177.00/40227 | 219.4 | 7.80 |

| 24A-2 | 120-2 | 38.100 | 22.23 | 25.22 | 11.10 | 95.8 | 99.7 | 35.70 | 4.80 | 45.44 | 254.00/57727 | 314.9 | 11.70 |

| 28A-2 | 140-2 | 44.450 | 25.40 | 25.22 | 12.70 | 103.3 | 107.9 | 41.00 | 5.60 | 48.87 | 344.80/78364 | 427.5 | 15.14 |

| 32A-2 | 160-2 | 50.800 | 28.58 | 31.55 | 14.27 | 123.3 | 128.1 | 47.80 | 6.40 | 58.55 | 453.60/103091 | 562.4 | 20.14 |

| 36A-2 | 180-2 | 57.150 | 35.71 | 35.48 | 17.46 | 138.6 | 144.4 | 53.60 | 7.20 | 65.84 | 560.50/127386 | 695.0 | 29.22 |

| 40A-2 | 200-2 | 63.500 | 39.68 | 37.85 | 19.85 | 151.9 | 158.8 | 60.00 | 8.00 | 71.55 | 707.60/160818 | 877.4 | 32.24 |

| 48A-2 | 240-2 | 76.200 | 47.63 | 47.35 | 23.81 | 183.4 | 190.8 | 72.39 | 9.50 | 87.83 | 1020.60/213955 | 1255.3 | 45.23 |

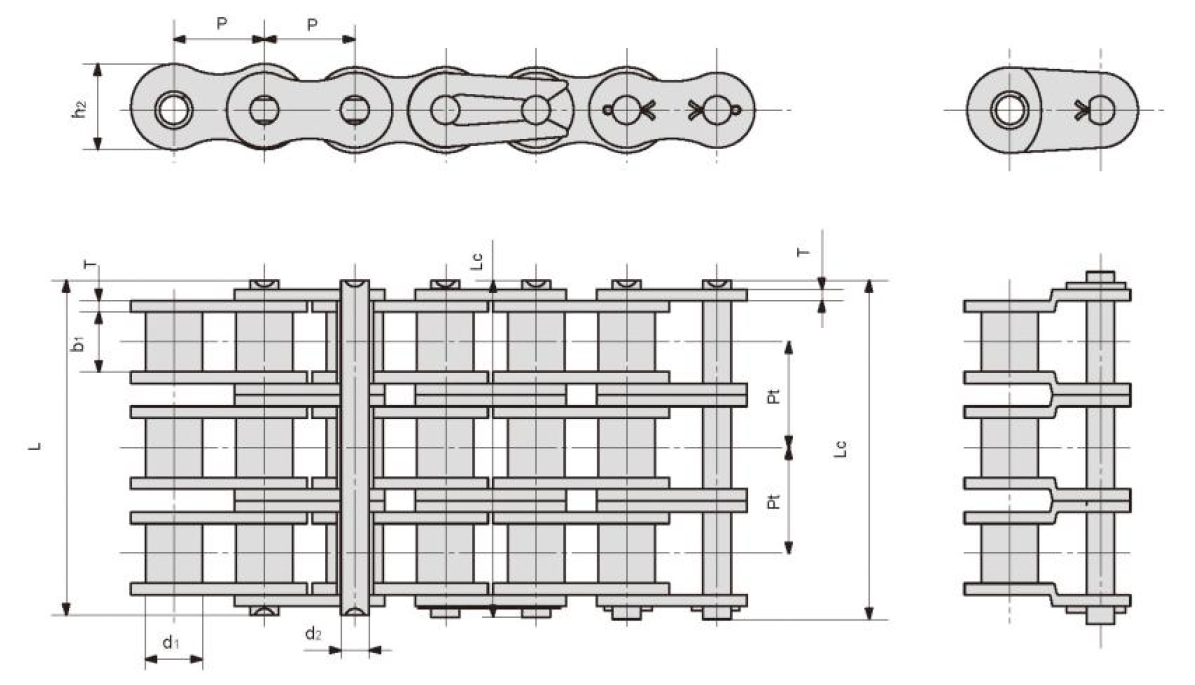

| DIN/ISO CHAIN NO. | ANSI CHAIN NO. | Pitch | Roller diameter | Width between inner plates | Pin diameter | Pin length | Inner plate depth | Plate thickness | Transverse pitch | Ultimate tensile strength | Average tensile strength | Weight per meter |

| DIN/ISO Cadena No | ANSI Cadena No | Paso | Diámetro rodillo | Ancho interior | Diámetro pasador | Longitud pasador | Altura placas | Ancho placas | Paso transversal | Resis. rotura | Resis. media tracción | Peso por metro |

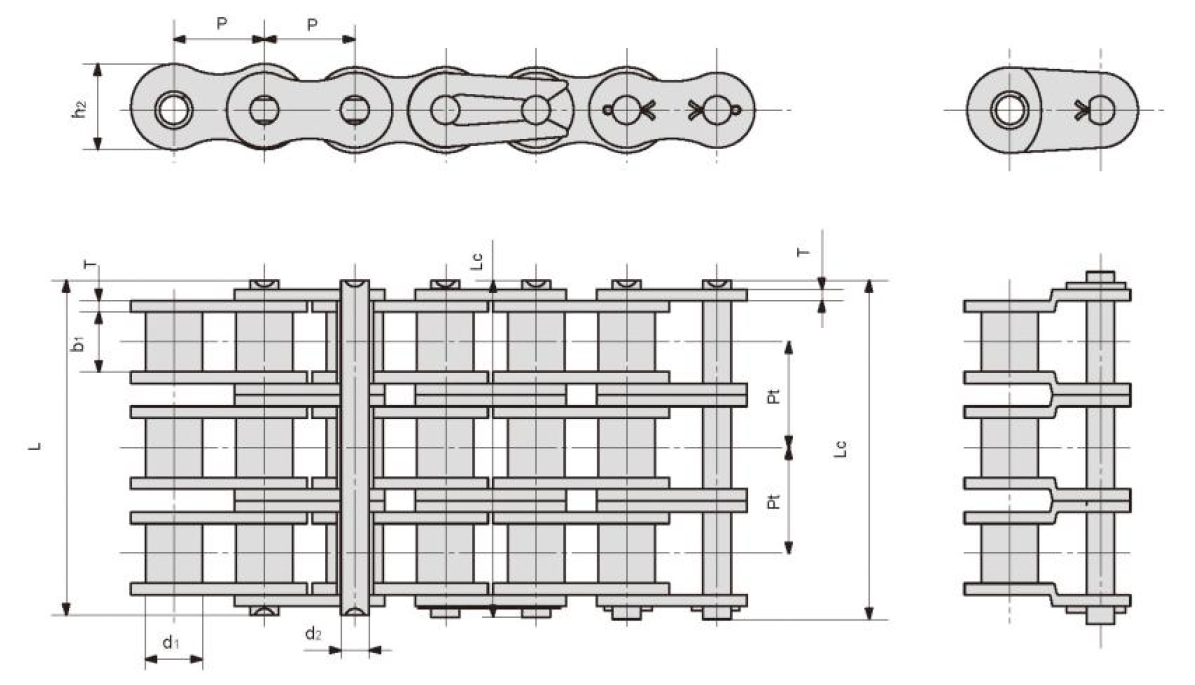

| P | d1 max | b1 min | d2 max | L max | Lc max | h2 max | T max | Pt | Q min | Q0 | q |

| mm | mm | mm | mm | mm | mm | mm | mm | mm | kN/LB | kN | kg/m |

| *04C-3 | *25-3 | 6.350 | 3.30 | 3.18 | 2.31 | 21.0 | 21.5 | 6.00 | 0.80 | 6.40 | 10.5/2386 | 12.6 | 0.44 |

| *06C-3 | *35-3 | 9.525 | 5.08 | 4.77 | 3.58 | 32.7 | 33.5 | 9.00 | 1.30 | 10.13 | 23.7/5386 | 28.6 | 1.05 |

| 08A-3 | 40-3 | 12.700 | 7.95 | 7.85 | 3.96 | 45.4 | 46.6 | 12.00 | 1.50 | 14.38 | 42.3/9614 | 50.0 | 1.90 |

| 10A-3 | 50-3 | 15.875 | 10.16 | 9.40 | 5.08 | 57.0 | 58.5 | 15.09 | 2.03 | 18.11 | 66.6/15136 | 77.8 | 3.09 |

| 12A-3 | 60-3 | 19.050 | 11.91 | 12.57 | 5.94 | 71.5 | 73.3 | 18.00 | 2.42 | 22.78 | 95.4/21682 | 111.1 | 4.54 |

| 16A-3 | 80-3 | 25.400 | 15.88 | 15.75 | 7.92 | 91.7 | 93.6 | 24.00 | 3.25 | 29.29 | 170.1/38659 | 198.4 | 7.89 |

| 20A-3 | 100-3 | 31.750 | 19.05 | 18.90 | 9.53 | 112.2 | 116.3 | 30.00 | 4.00 | 35.76 | 265.5/60341 | 309.6 | 11.77 |

| 24A-3 | 120-3 | 38.100 | 22.23 | 25.22 | 11.10 | 141.4 | 145.2 | 35.70 | 4.80 | 45.44 | 381.0/86591 | 437.2 | 17.53 |

| 28A-3 | 140-3 | 44.450 | 25.40 | 25.22 | 12.70 | 152.2 | 156.8 | 41.00 | 5.60 | 48.87 | 517.2/117545 | 593.3 | 22.20 |

| 32A-3 | 160-3 | 50.800 | 28.58 | 31.55 | 14.27 | 181.8 | 186.6 | 47.80 | 6.40 | 58.55 | 680.4/154636 | 780.6 | 30.02 |

| 36A-3 | 180-3 | 57.150 | 35.71 | 35.48 | 17.46 | 204.4 | 210.2 | 53.60 | 7.20 | 65.84 | 840.7/191068 | 983.6 | 38.22 |

| 40A-3 | 200-3 | 63.500 | 39.68 | 37.85 | 19.85 | 223.5 | 230.4 | 60.00 | 8.00 | 71.55 | 1061.4/241227 | 1217.8 | 49.03 |

| 48A-3 | 240-3 | 76.200 | 47.63 | 47.35 | 23.81 | 271.3 | 278.6 | 72.39 | 9.50 | 87.83 | 1530.9/347932 | 1756.5 | 71.60 |

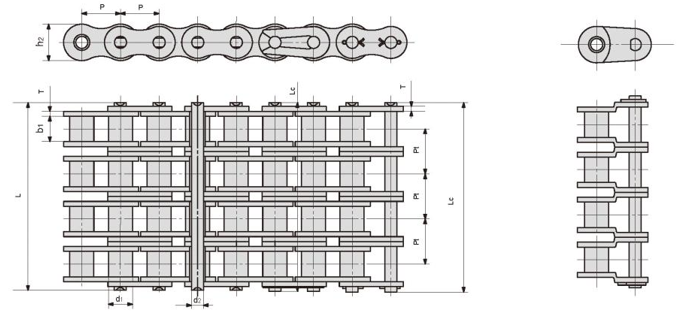

DIN/ISO

CHAIN NO. | ANSI

CHAIN NO. | Pitch | Roller

diameter | Width

between

inner plates | Pin

diameter | Pin length | Inner

plate

depth | Plate

thickness | Transverse

pitch | Ultimate

tensile

strength | Average

tensile

strength | Weight

per meter |

PLW

Cadena

No | ANSI

Cadena

No | Paso | Diámetro

rodillo | Ancho

interior | Diámetro

pasador | Longitud pasador | Altura

placas | Ancho

placas | Paso

transversal | Resis.rotura | Resis.

media

tracción | Peso

por

metro |

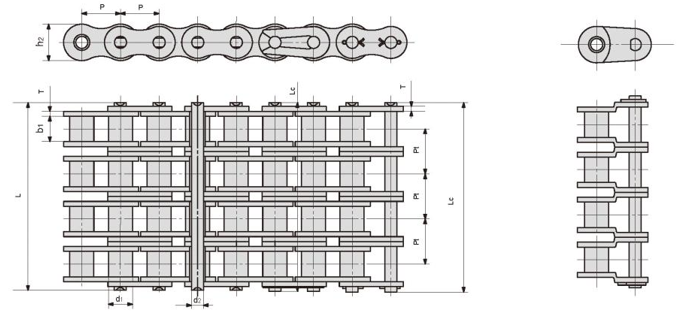

| P | d1

max | b1

min | d2

max | L

max | Lc

max | h2

max | T

max | Pt | Q

min | Qo | q |

| mm | mm | mm | mm | mm | mm | mm | mm | mm | Kn/LB | Kn | Kg/m |

| 08A-4 | 40-4 | 12.700 | 7.95 | 7.85 | 3.96 | 59.8 | 61.0 | 12.00 | 1.50 | 14.38 | 56.4/12687 | 62.04 | 2.57 |

| 10A-4 | 50-4 | 15.875 | 10.16 | 9.40 | 5.08 | 75.1 | 76.6 | 15.09 | 2.03 | 18.11 | 88.8/19976 | 97.68 | 4.30 |

| 12A-4 | 60-4 | 19.050 | 11.91 | 12.57 | 5.94 | 94.4 | 96.1 | 18.00 | 2.42 | 22.78 | 127.2/28614 | 139.92 | 6.21 |

| 16A-4 | 80-4 | 25.400 | 15.88 | 15.75 | 7.92 | 121.0 | 124.4 | 24.00 | 3.25 | 29.29 | 226.8/51020 | 249.48 | 10.37 |

| 20A-4 | 100-4 | 31.750 | 19.05 | 18.90 | 9.53 | 147.8 | 152.1 | 30.00 | 4.00 | 35.76 | 354/79635 | 389.40 | 15.60 |

| 24A-4 | 120-4 | 38.100 | 22.23 | 25.22 | 11.10 | 187.0 | 190.8 | 35.70 | 4.80 | 45.44 | 508/114278 | 558.80 | 23.56 |

| 08A-5 | 40-5 | 12.700 | 7.95 | 7.85 | 3.96 | 74.2 | 75.4 | 12.00 | 1.50 | 14.38 | 70.5/15859 | 77.55 | 3.19 |

| 10A-5 | 50-5 | 15.875 | 10.16 | 9.40 | 5.08 | 93.2 | 94.7 | 15.09 | 2.03 | 18.11 | 111/24970 | 122.10 | 5.37 |

| 12A-5 | 60-5 | 19.050 | 11.91 | 12.57 | 5.94 | 117.0 | 118.8 | 18.00 | 2.42 | 22.78 | 159/35768 | 174.90 | 7.75 |

| 16A-5 | 80-5 | 25.400 | 15.88 | 15.75 | 7.92 | 149.9 | 153.7 | 24.00 | 3.25 | 29.29 | 283.5/63775 | 311.85 | 12.96 |

| 20A-5 | 100-5 | 31.750 | 19.05 | 18.90 | 9.53 | 183.6 | 187.9 | 30.00 | 4.00 | 35.76 | 442.5/99543 | 486.75 | 19.46 |

| 24A-5 | 120-5 | 38.100 | 22.23 | 25.22 | 11.10 | 232.3 | 236.1 | 35.70 | 4.80 | 45.44 | 635/142848 | 698.50 | 29.40 |

| 08A-6 | 40-6 | 12.700 | 7.95 | 7.85 | 3.96 | 88.5 | 89.8 | 12.00 | 1.50 | 14.38 | 84.6/19031 | 93.06 | 3.83 |

| 10A-6 | 50-6 | 15.875 | 10.16 | 9.40 | 5.08 | 111.3 | 112.8 | 15.09 | 2.03 | 18.11 | 133.2/29964 | 146.52 | 6.43 |

| 12A-6 | 60-6 | 19.050 | 11.91 | 12.57 | 5.94 | 139.8 | 141.8 | 18.00 | 2.42 | 22.78 | 190.8/42921 | 209.80 | 9.31 |

| 16A-6 | 80-6 | 25.400 | 15.88 | 15.75 | 7.92 | 179.2 | 183.0 | 24.00 | 3.25 | 29.29 | 340.2/76530 | 374.22 | 15.50 |

| 20A-6 | 100-6 | 31.750 | 19.05 | 18.90 | 9.53 | 219.4 | 223.7 | 30.00 | 4.00 | 35.76 | 531/119452 | 584.10 | 23.36 |

| 24A-6 | 120-6 | 38.100 | 22.23 | 25.22 | 11.10 | 278.0 | 282.0 | 35.70 | 4.80 | 45.44 | 762/171417 | 838.20 | 35.30 |

| 08A-8 | 40-8 | 12.700 | 7.95 | 7.85 | 3.96 | 117.3 | 118.5 | 12.00 | 1.50 | 14.38 | 112.8/25375 | 124.08 | 5.11 |

| 10A-8 | 50-8 | 15.875 | 10.16 | 9.40 | 5.08 | 147.5 | 149.0 | 15.09 | 2.03 | 18.11 | 177.6/39952 | 195.36 | 8.59 |

Frequently Asked Questions (FAQ)

Q: What is the difference between A-Series and B-Series roller chains?

A: A-Series (ANSI) chains follow American standards and typically have a smaller pin diameter and different plate thickness compared to the European B-Series (ISO/DIN). They are generally preferred for higher-speed applications in North America and Asia.

Q: Can I use your carbon steel chain in a wash-down environment?

A: For environments with frequent moisture or chemical exposure, we recommend our Stainless Steel (304/316) series or our Dacromet-coated chains, which provide superior corrosion resistance compared to standard carbon steel.

Q: How do I know when it is time to replace my roller chain?

A: The most reliable method is measuring "stretch." If the chain has elongated by more than 2% of its original pitch length, it will no longer seat correctly on the sprocket teeth and should be replaced immediately to avoid system failure.

Q: Are your chains compatible with standard sprockets?

A: Yes, our A-Series chains are designed to be fully interchangeable with any standard ANSI-specification sprockets, ensuring a hassle-free replacement process.

Would you like me to generate a meta description and SEO title tags for this product to further enhance its search visibility?

English

Español

العربية

Français

Русский

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

አማርኛ

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Kiswahili

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

Հայերեն

עברית

Latine

Dansk

اردو

Shqip

বাংলা

Hrvatski

Afrikaans

Gaeilge

Eesti keel

Māori

සිංහල

नेपाली

Oʻzbekcha

latviešu

অসমীয়া

Aymara

Azərbaycan dili

Bamanankan

Euskara

Беларуская мова

भोजपुरी