Corrosion Resistant/Dacromet-Plated Chain (25DR, 35DR, 41DR, 50DR)

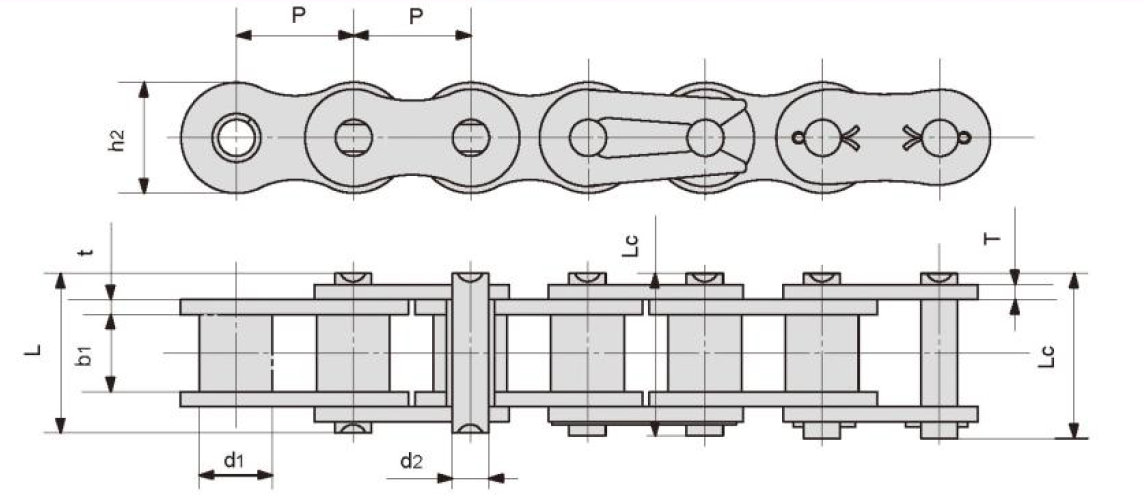

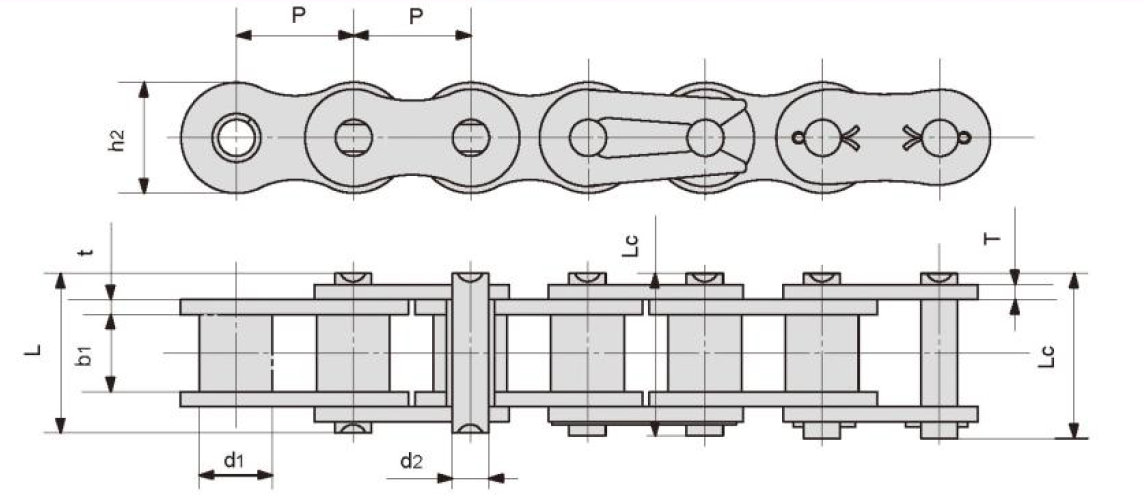

| CHAIN NO. | Pitch | Roller

diameter | Width

between

inner plates | Pin

diameter | Pin length | Inner

plate

depch | Plate

thickness | Breaking load | Weight

per meter |

| Cadena no | Paso | Diámetro

rodillo | Ancho

interior | Diámetro

pasador | Longitud pasador | Altura

placas | Ancho

placas | Carga rotura | Peso

por metro |

| P | d1

max | b1

min | d2

max | L

max | Lc

max | h2

max | t/T

max | Q | q |

| mm | mm | mm | mm | mm | mm | mm | mm | kN/LB | kg/m |

| *25DR | 6.350 | 3.30 | 3.18 | 2.31 | 7.90 | 8.40 | 6.00 | 0.80 | 3.50/795 | 0.15 |

| *35DR | 9.525 | 5.08 | 4.77 | 3.58 | 12.40 | 13.17 | 9.00 | 1.30 | 7.90/1795 | 0.33 |

| 41DR | 12.700 | 7.77 | 6.25 | 3.58 | 13.75 | 15.00 | 9.91 | 1.30 | 6.67/1516 | 0.41 |

| 40DR | 12.700 | 7.95 | 7.85 | 3.96 | 16.60 | 17.80 | 12.00 | 1.50 | 14.10/3205 | 0.62 |

| 50DR | 15.875 | 10.16 | 9.40 | 5.08 | 20.70 | 22.20 | 15.09 | 2.03 | 22.20/5045 | 1.02 |

| 60DR | 19.050 | 11.91 | 12.57 | 5.94 | 25.90 | 27.70 | 18.00 | 2.42 | 31.80/7227 | 1.50 |

| 80DR | 25.400 | 15.88 | 15.75 | 7.92 | 32.70 | 35.00 | 24.00 | 3.25 | 56.70/12886 | 2.60 |

| 100DR | 31.750 | 19.05 | 18.90 | 9.53 | 40.40 | 44.70 | 30.00 | 4.00 | 88.50/20114 | 3.91 |

| 120DR | 38.100 | 22.23 | 25.22 | 11.10 | 50.30 | 54.30 | 35.70 | 4.80 | 127.00/28864 | 5.62 |

| 140DR | 44.450 | 25.40 | 25.22 | 12.70 | 54.40 | 59.00 | 41.00 | 5.60 | 172.40/39182 | 7.50 |

| 160DR | 50.800 | 28.58 | 31.55 | 14.27 | 64.80 | 69.60 | 47.80 | 6.40 | 226.80/51545 | 10.10 |

| 04BDR | 6.000 | 4.00 | 2.80 | 1.85 | 6.80 | 7.80 | 5.00 | 0.60 | 3.00/682 | 0.11 |

| 05BDR | 8.000 | 5.00 | 3.00 | 2.31 | 8.20 | 8.90 | 7.10 | 0.80 | 5.00/1136 | 0.20 |

| 06BDR | 9.525 | 6.35 | 5.72 | 3.28 | 13.15 | 14.10 | 8.20 | 1.30 | 9.00/2045 | 0.41 |

| 08BDR | 12.700 | 8.51 | 7.75 | 4.45 | 16.70 | 18.20 | 11.80 | 1.60 | 18.00/4091 | 0.69 |

| 10BDR | 15.875 | 10.16 | 9.65 | 5.08 | 19.50 | 20.90 | 14.70 | 1.70 | 22.40/5091 | 0.93 |

| 12BDR | 19.050 | 12.07 | 11.68 | 5.72 | 22.50 | 24.20 | 16.00 | 1.85 | 29.00/6591 | 1.15 |

| 16BDR | 25.400 | 15.88 | 17.02 | 8.28 | 36.10 | 37.40 | 21.00 | 4.15/3.1 | 60.00/13636 | 2.71 |

| 20BDR | 31.750 | 19.05 | 19.56 | 10.19 | 41.30 | 45.00 | 26.40 | 4.5/3.5 | 95.00/21591 | 3.70 |

| 24BDR | 38.100 | 25.40 | 25.40 | 14.63 | 53.40 | 57.80 | 33.20 | 6.0/4.8 | 160.00/36364 | 7.10 |

| 28BDR | 44.450 | 27.94 | 30.99 | 15.90 | 65.10 | 69.50 | 36.70 | 7.5/6.0 | 200.00/45455 | 8.50 |

| 32BDR | 50.800 | 29.21 | 30.99 | 17.81 | 66.00 | 71.00 | 42.00 | 7.0/6.0 | 250.00/56818 | 10.25 |

1. Core Definition & Product Overview

Dacromet-plated chain (also referred to as "Dacromet anti-corrosion chain") is a high-performance corrosion-resistant variant of roller chains (including standard pitch, double pitch, and hollow pin chains) processed with the Dacromet surface treatment technology. Unlike traditional electroplating (e.g., zinc plating, nickel plating), Dacromet plating forms a dense, non-electrolytic inorganic coating on the chain’s metal surface (pins, bushings, rollers, link plates), providing superior corrosion resistance, high-temperature resistance, and anti-wear performance for harsh working environments.

2. Dacromet Plating Process & Coating Characteristics

2.1 Core Plating Process

The Dacromet coating is composed of zinc-aluminum flake powder (Zn-Al alloy, typical ratio: 80% Zn + 20% Al) and a special inorganic binder. The core process steps are:

Pre-treatment: Degreasing, derusting, and phosphatizing the chain components to remove surface oil, rust, and oxides, ensuring coating adhesion.

Dipping/Spin-Coating: Immersing or spin-coating the cleaned components in Dacromet coating liquid to form a uniform thin film.

Curing: Baking at 300±10℃ for 20-30 minutes to cross-link the coating and form a stable, dense protective layer (thickness: 8-12 μm for standard grade, 15-20 μm for heavy-duty grade).

Post-inspection: Testing coating thickness, adhesion, and corrosion resistance to meet industry standards (e.g., ISO 10683).

2.2 Key Coating Advantages (vs. Traditional Anti-Corrosion Treatments)

| Characteristic | Dacromet-Plated Chain | Zinc-Plated Chain | Hot-Dip Galvanized Chain |

| Corrosion Resistance | Salt spray test: ≥1000 hours (no red rust) | Salt spray test: 200-500 hours | Salt spray test: 500-800 hours |

| High-Temperature Resistance | Stable performance up to 300℃ (no coating peeling) | Decomposes at ≥120℃ (zinc oxide formation) | Peels at ≥200℃ |

| Coating Adhesion | Excellent (resists impact/abrasion, no peeling) | Poor (easy to peel under impact) | Brittle coating (prone to cracking) |

| Environmental Friendliness | Chromium-free (meets RoHS/REACH standards) | Contains hexavalent chromium (restricted in EU/US) | High zinc consumption, heavy pollution |

| Uniformity | Coating covers blind holes/gaps (e.g., pin-bushing fit) | Uneven coating in blind areas | Thick, uneven coating (affects chain fit) |

3. Core Performance Parameters

| Parameter Category | Specification/Value |

| Base Chain Compatibility | Standard roller chain (ANSI 35/40/50, ISO 06B/08B/10B), double pitch chain (08B-2/40H) |

| Coating Thickness | Standard grade: 8-12 μm; Heavy-duty grade: 15-20 μm |

| Tensile Strength | ≥95% of the base chain (coating does not reduce mechanical strength) |

| Working Temperature | -40℃ to +300℃ (continuous operation) |

| Corrosion Resistance | Neutral salt spray test (ASTM B117): ≥1000h (no red rust), ≥2000h (no white rust) |

| Wear Resistance | Coefficient of friction: 0.15-0.20 (10% lower than zinc-plated chain) |

| Chemical Resistance | Resistant to weak acids, alkalis, oil, and most industrial chemicals |

4. Typical Application Scenarios

Dacromet-plated chains are designed for harsh environments with high humidity, corrosive media, or temperature fluctuations, and are widely used in:

4.1 Industrial Conveying

Seafood processing line conveyors (saltwater corrosion resistance)

Chemical plant material conveyors (resistant to acid/alkali mist)

Outdoor conveyor systems (rain, UV, and atmospheric corrosion resistance)

4.2 Agricultural Machinery

Irrigation equipment transmission chains (humid soil/chemical fertilizer corrosion)

Greenhouse automation systems (high humidity, pesticide corrosion)

Livestock breeding equipment (ammonia gas, manure corrosion)

4.3 Automotive & Heavy Machinery

Automotive chassis auxiliary transmission chains (road salt, water, mud corrosion)

Construction machinery (outdoor construction, rain, and concrete slurry corrosion)

Marine equipment (saltwater spray, high humidity marine environment)

4.4 Food & Pharmaceutical Industry

5. Installation & Maintenance Notes

Storage: Store in a dry, ventilated warehouse; avoid direct contact with acidic/alkaline substances or sharp objects (to prevent coating damage).

Installation: Do not use excessive force during assembly (e.g., hammering pins) to avoid scratching the coating; ensure sprocket matching (same pitch/spec as base chain).

Lubrication: Use anti-corrosion lubricants (e.g., lithium-based grease with rust inhibitors) to further enhance protection; re-lubricate every 500 hours of operation in harsh environments.

Inspection: Regularly check for coating damage (repair with Dacromet touch-up paint for small areas); replace the chain if coating peeling or red rust occurs over ≥10% of the surface.

English

Español

العربية

Français

Русский

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

አማርኛ

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Kiswahili

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

Հայերեն

עברית

Latine

Dansk

اردو

Shqip

বাংলা

Hrvatski

Afrikaans

Gaeilge

Eesti keel

Māori

සිංහල

नेपाली

Oʻzbekcha

latviešu

অসমীয়া

Aymara

Azərbaycan dili

Bamanankan

Euskara

Беларуская мова

भोजपुरी