Hollow Pin Conveyor Chains(ZC Series)

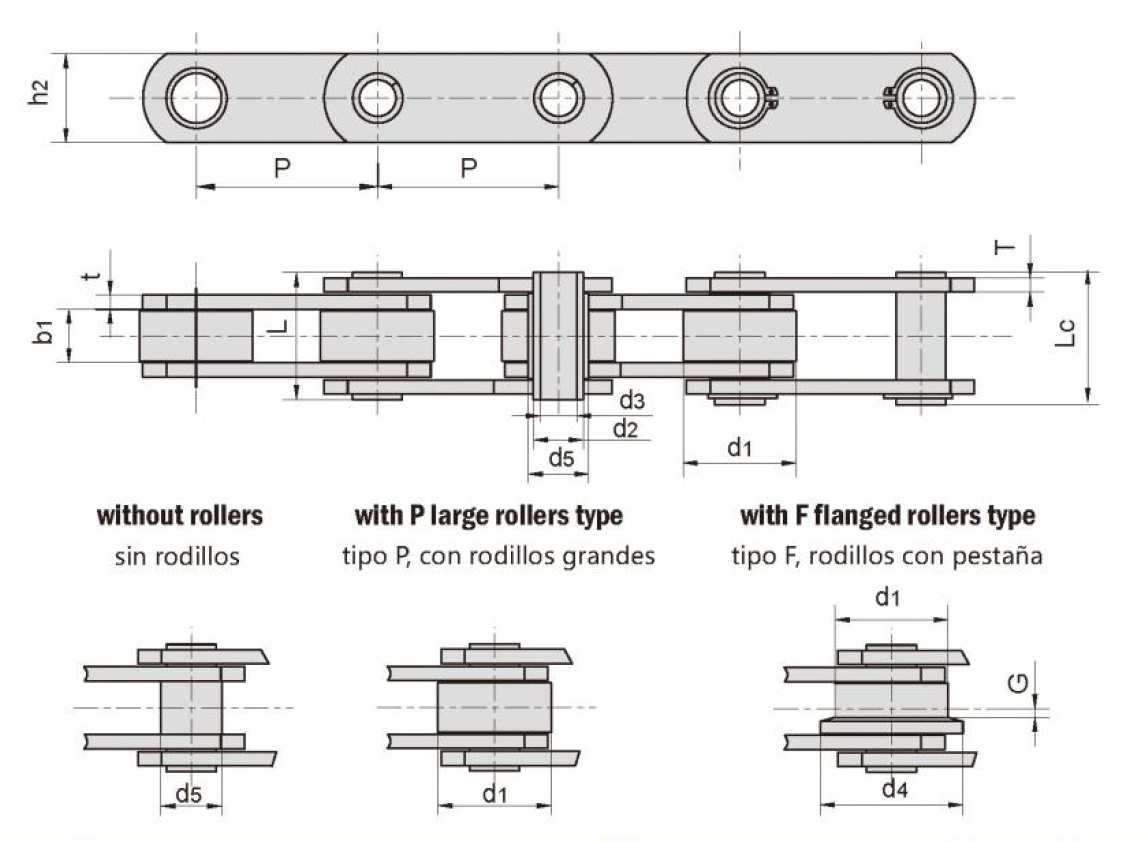

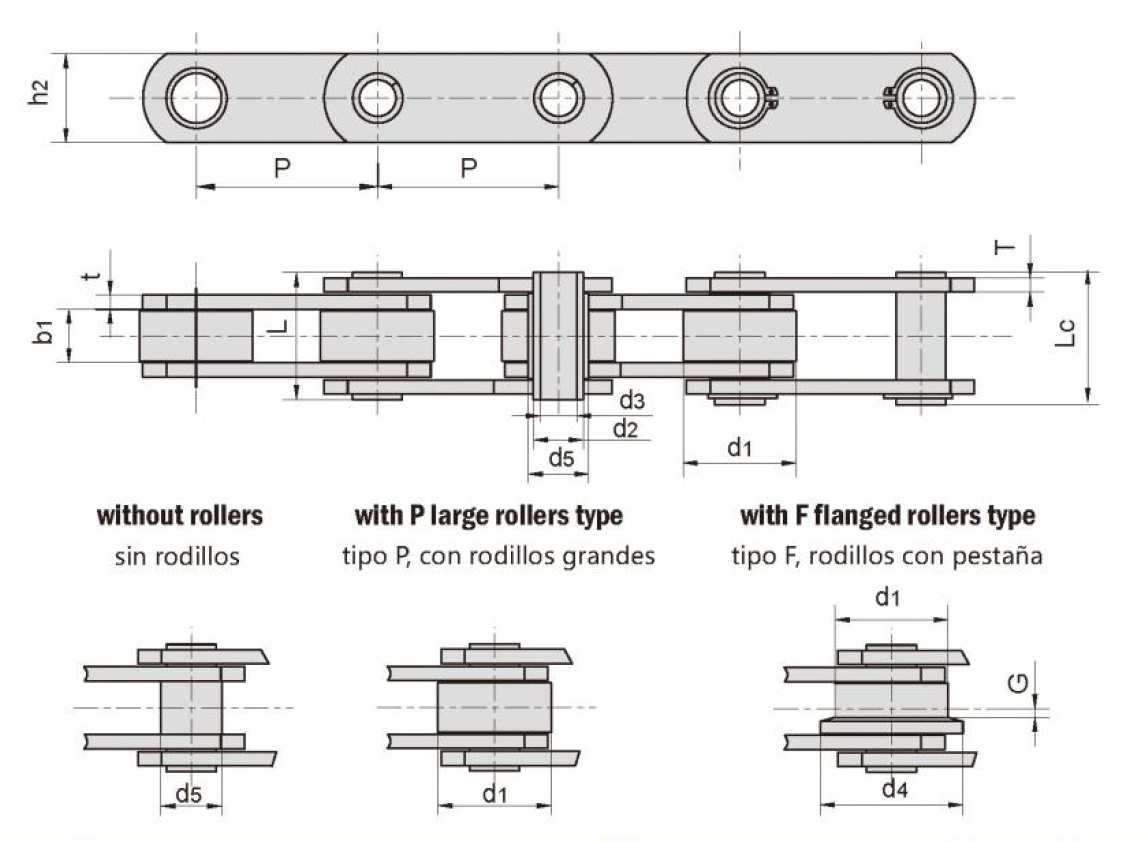

| CH AIN NO. | Pitch | Roller

dimension | Bush

diameter | Plate depth |

| Cadena No | Paso | Diametro

rodillo | Diametro

casquillo | Allura

placas |

| P | d1

max | d4

max | G | ds

max | h2

max |

| mm | mm | mm | mm | mm | mm |

| ZC21 | 38.1 | 50.8 | 63.5 | 76.2 | - | - | - | 25.40 | - | - | 11.0 | 18.0 |

| ZC40 | 50.8 | 63.5 | 76.2 | 88.9 | 101.6 | 127.0 | 152.4 | 31.75 | 40.0 | 2.5 | 17.0 | 25.0 |

| ZC60 | 76.2 | 88.9 | 101.6 | 127.0 | 152.4 | 177.8 | 203.2 | 47.50 | 60.0 | 3.5 | 23.0 | 40.0 |

| ZC150 | 101.6 | 127.0 | 152.4 | 177.8 | 203.2 | 228.6 | 254.0 | 66.70 | 82.0 | 4.0 | 33.0 | 50.0 |

| ZC300 | 152.4 | 177.8 | 203.2 | 254.0 | 304.8 | - | - | 88.90 | 114.0 | 8.5 | 38.0 | 60.0 |

| CH AIN NO. | Width

between

inner plates | Pin

diameter | Pin length | Plate thickness | Breaking load |

| Cadena No | Ancho

interior | Diámetro

pasador | Longitud

pasador | Ancho

placas | Carga de rotura |

b1

min | d2

max | d3

max | L

max | Lc

max | t/T

max | Q

min | *Q

min |

| mm | mm | mm | mm | mm | mm | kN/LB | kN/LB |

| ZC21 | 12.7 | 9.0 | 6.5 | 26.0 | 27.5 | 2.5 | 21.0/4772 | 27.1/6159 |

| ZC40 | 15.0 | 14.0 | 10.2 | 36.4 | 37.7 | 4.0 | 40.0/9091 | 50.0/11362 |

| ZC60 | 19.0 | 19.0 | 13.2 | 45.0 | 46.5 | 5.0/4.0 | 60.0/13636 | 120.0/27270 |

| ZC150 | 26.0 | 26.9 | 20.2 | 58.0 | 60.5 | 7.0/5.0 | 150.0/34087 | 190.0/43177 |

| ZC300 | 38.0 | 32.0 | 22.5 | 83.0 | 85.0 | 10.0/8.0 | 300.0/68175 | 380.0/86362 |

*Q Higher breaking load with hardened plates

*Q: Placas endurecidas, mayor carga de rotura

1. Core Definition & Product Overview

The ZC Series Hollow Pin Conveyor Chain is a specialized heavy-duty conveyor chain engineered for material handling and industrial conveying applications. Its defining feature is the hollow cylindrical pin (instead of solid pins in standard chains), which allows the insertion of custom attachments (e.g., pins, brackets, crossbars, or fixtures) through the pin’s central bore. Designed for high load capacity, easy customization, and reliable operation in harsh conveying environments, the ZC Series is widely used in automated production lines, bulk material handling, and heavy-duty transfer systems.

2. Key Design & Structural Features

2.1 Core Structural Components

The ZC Series chain consists of precision-machined components to ensure durability and compatibility with custom attachments:

Hollow Pins: Cold-drawn alloy steel (40Cr) with a smooth internal bore (tolerance ±0.02mm) and case-hardened surface (HRC 58-62) for wear resistance; available in bore diameters from 8mm to 30mm (per chain size).

Inner/Outer Link Plates: High-strength carbon steel (50Mn) with quenched and tempered heat treatment (HRC 40-45) to withstand impact and tensile loads; stamped with CNC dies for dimensional consistency.

Bushings & Rollers: Seamless steel bushings (interference-fit with inner plates) and hardened steel rollers (for low-friction engagement with sprockets); sealed lubrication options available for dust/waterproof performance.

Connecting Links: Drop-forged carbon steel connecting links with cotter pins or spring clips for easy installation/removal; compatible with all ZC Series chain sizes.

2.2 Unique Advantages (vs. Standard Solid Pin Conveyor Chains)

| Characteristic | ZC Series Hollow Pin Chain | Standard Solid Pin Conveyor Chain |

| Custom Attachment Flexibility | High (attachments mounted via hollow pins, no welding/modification) | Low (attachments require welding or specialized machining) |

| Weight-to-Load Ratio | Optimized (hollow pins reduce weight by 15-20% vs. solid pins) | Higher weight (solid pins add unnecessary mass) |

| Maintenance Accessibility | Easy (pins can be removed/replaced without disassembling the entire chain) | Difficult (solid pins require press fitting/extraction) |

| Attachment Stability | Superior (attachments secured through full pin bore, no lateral movement) | Poor (attachments welded/bracketed, prone to loosening) |

| Adaptability | Customizable for variable pitch/spacing of attachments | Fixed attachment spacing (limited flexibility) |

3. ZC Series Technical Specifications

| Model (ZC Series) | Pitch (mm) | Hollow Pin Bore Dia. (mm) | Tensile Strength (kN) | Working Load Limit (kN) | Plate Thickness (mm) | Recommended Sprocket Teeth |

| ZC32B | 50.8 | 12 | 125 | 25 | 4.0 | 8-24 |

| ZC40B | 63.5 | 16 | 180 | 36 | 5.0 | 8-24 |

| ZC50B | 76.2 | 20 | 250 | 50 | 6.0 | 10-28 |

| ZC60B | 95.25 | 25 | 380 | 76 | 7.5 | 10-28 |

| ZC80B | 127.0 | 30 | 600 | 120 | 10.0 | 12-32 |

Additional Performance Parameters

Operating Temperature: Standard grade: -20℃ to +150℃; High-temperature grade: -40℃ to +250℃ (with heat-resistant lubrication)

Lubrication Options: Oil bath, grease injection, sealed self-lubricating (PTFE-impregnated bushings)

Corrosion Resistance: Optional zinc plating, Dacromet plating, or stainless steel construction (for wet/corrosive environments)

Service Life: ≥8,000 hours (under rated load, proper lubrication, and alignment)

4. Typical Applications & Attachment Configurations

The ZC Series is designed for customizable material handling across industries, with common attachment setups and use cases:

4.1 Core Attachment Types (Easily Installed via Hollow Pins)

Crossbar Attachments: Steel bars inserted through hollow pins for conveying pallets, boxes, or bulk containers.

Cleat Attachments: Angled plates mounted on pins to prevent material sliding on inclined conveyors (e.g., grain, gravel).

Bracket Attachments: Custom brackets for holding fixtures, tooling, or product carriers in automated assembly lines.

Pin Stop Attachments: Removable pins for indexing or stopping workpieces at specific conveyor stations.

4.2 Industry Applications

Automotive Manufacturing: Conveying car body components, engine parts, and assembly line workpieces (custom bracket attachments).

Food & Beverage: Handling crates, pallets, and bulk ingredients (stainless steel ZC Series for washdown environments).

Construction & Mining: Conveying aggregates, gravel, and construction materials (heavy-duty ZC60B/ZC80B with cleat attachments).

Warehousing & Logistics: Pallet conveyors, automated storage/retrieval systems (AS/RS), and parcel sorting lines.

Recycling & Waste Management: Conveying mixed waste, plastic, or metal scrap (corrosion-resistant Dacromet-plated ZC Series).

Packaging Machinery: Indexing conveyors for carton filling, sealing, and labeling (precision crossbar attachments).

5. Installation & Maintenance Guidelines

5.1 Installation Best Practices

Sprocket Alignment: Ensure sprocket shafts are parallel (misalignment ≤0.8mm/m) to prevent uneven wear on pins and bushings.

Attachment Installation: Insert attachment pins through hollow bores with a press fit (avoid hammering to prevent pin deformation); secure with lock washers or cotter pins.

Tension Adjustment: Maintain slack of 1-2% of chain length (e.g., 10-20mm for 10m chain) to avoid excessive tension on hollow pins.

Sprocket Matching: Use ZC Series dedicated sprockets (tooth profile optimized for hollow pin chain engagement) to maximize service life.

5.2 Maintenance Protocols

Lubrication: For standard grades, apply high-viscosity conveyor chain oil (ISO VG 150) every 500 operating hours; for sealed grades, inspect lubricant levels every 2,000 hours.

Inspection:

Check hollow pin bore wear (replace if bore diameter increases by ≥0.1mm).

Inspect link plates for cracks (use magnetic particle testing for heavy-duty applications).

Verify attachment tightness (retorque/replace pins if loose) every 1,000 hours.

Replacement: Replace entire chain sections if ≥5% of pins show excessive wear; do not mix new/used chain segments (causes uneven load distribution).

6. Quality Assurance & Compliance

Manufacturing Standards: Produced to ISO 606 (Roller Chains and Bush Chains) and GB/T 1243 (Chinese National Standard for Conveyor Chains) with full traceability of raw materials.

Testing Requirements: Every batch undergoes:

Tensile strength testing (universal testing machine).

Dimensional inspection of hollow pin bore (CNC measuring equipment).

Wear resistance testing (accelerated life test rig).

Corrosion resistance testing (salt spray test for plated variants).

Certifications: CE (for EU market), RoHS (environmentally compliant), and ISO 9001 (quality management system).

English

Español

العربية

Français

Русский

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

አማርኛ

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Kiswahili

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

Հայերեն

עברית

Latine

Dansk

اردو

Shqip

বাংলা

Hrvatski

Afrikaans

Gaeilge

Eesti keel

Māori

සිංහල

नेपाली

Oʻzbekcha

latviešu

অসমীয়া

Aymara

Azərbaycan dili

Bamanankan

Euskara

Беларуская мова

भोजपुरी